Arc/Hole Speed

Arc speed control can be used on holes or when cutting arcs (such as rounded corners).

The following global variables are used:

| Global Variable number | Description |

|---|---|

| 7606 | Arc Speed |

| 7609 | Arcs Slow % |

| 9790 | Arc Speed enable/disable flag |

| 9791 | Arcs Diameter |

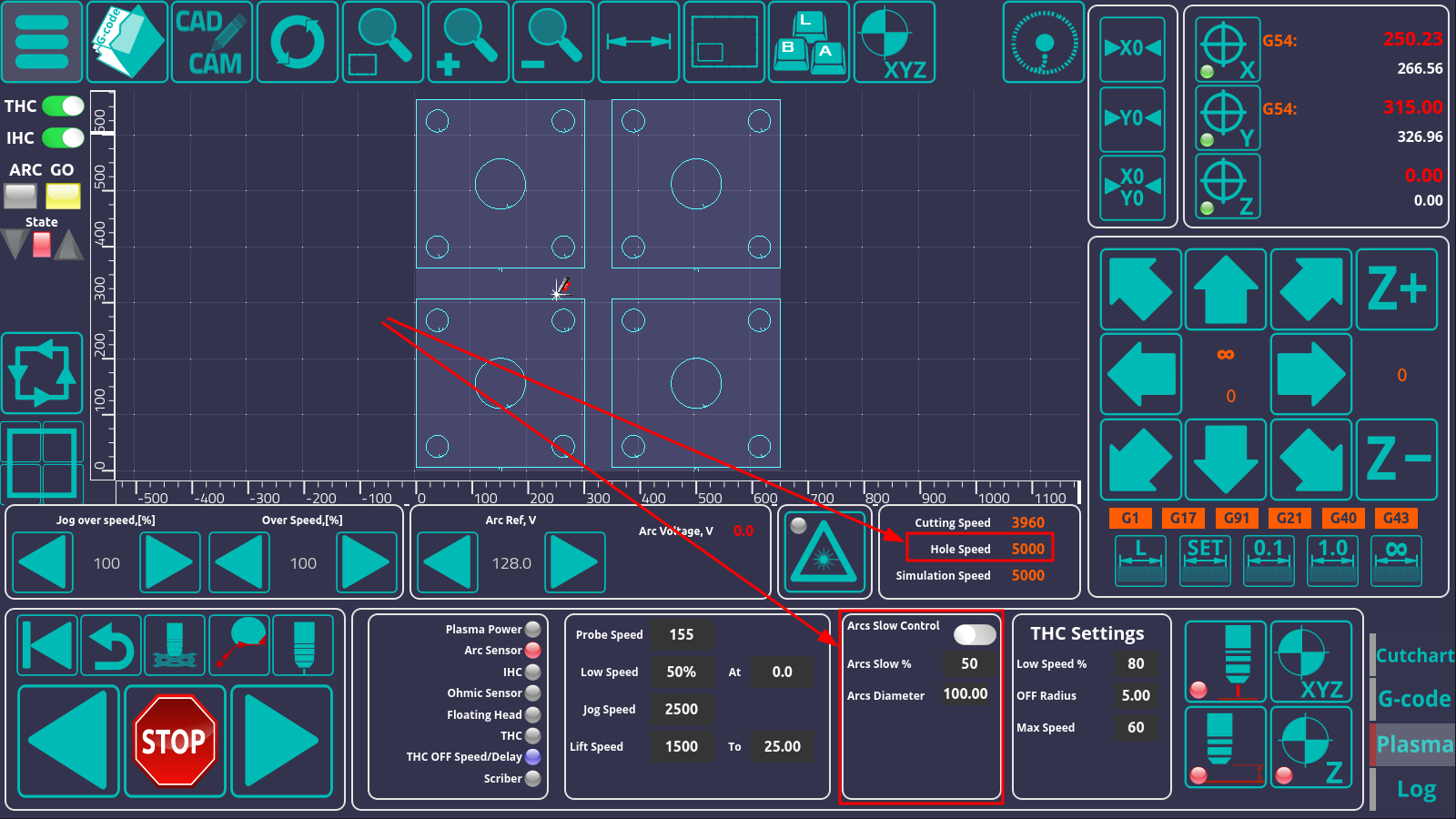

These settings are available on the main screen of some myCNC profiles (such as the default X1366P profile):

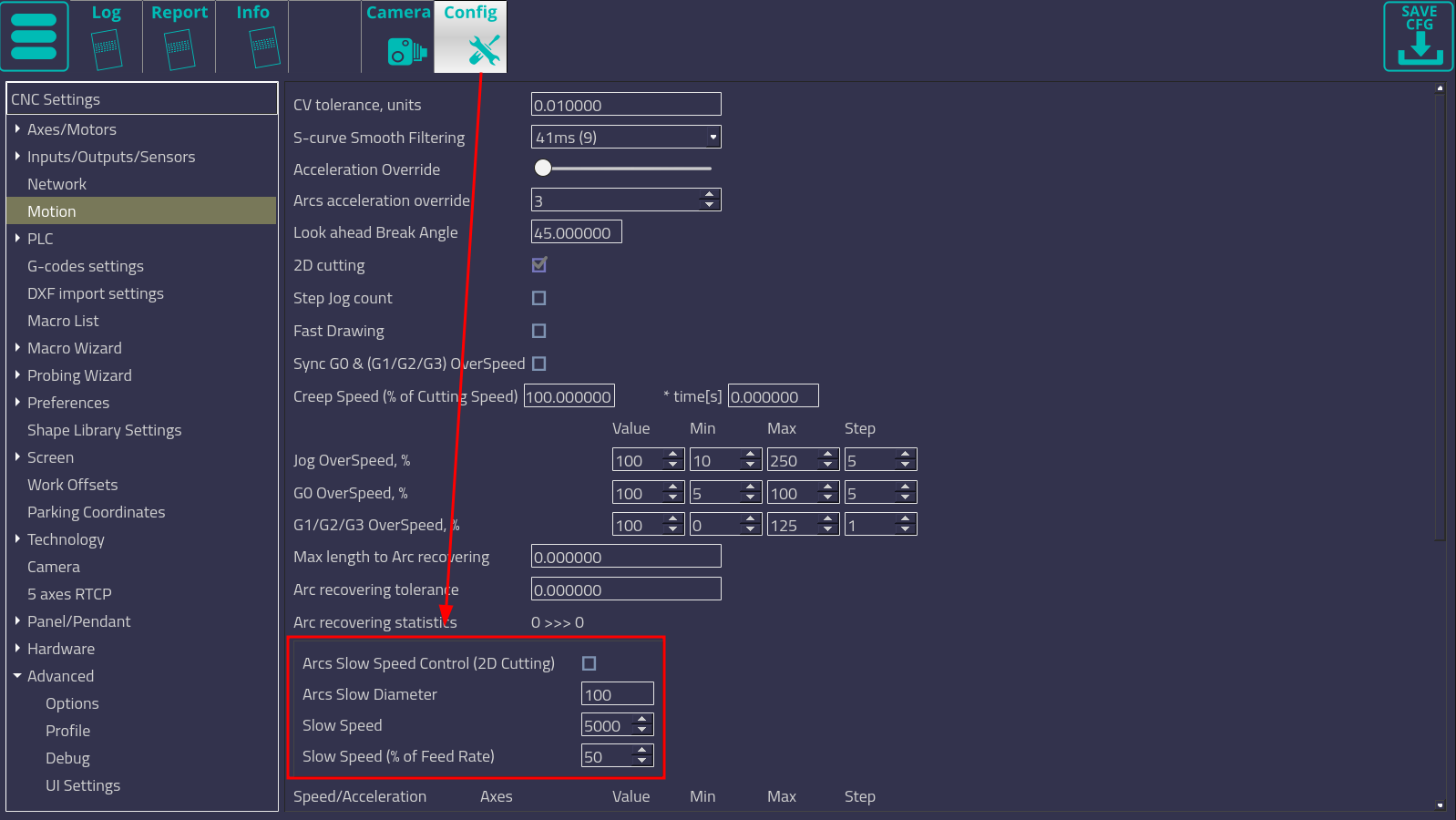

Additionally, this information can also be accessed via the Motion tab in the Configuration section of the myCNC software:

- Enable/disable arc speed control. Note that enabling arc speed control will overwrite the speed F-codes that may be present in the G-code program. For more info on speed priorities, see the following manual: Speed Priority

- Arc Slow Diameter. This specifies the maximum diameter for the arc to automatically enable arc / hole cutting speed. If the system sees an arc/hole with a diameter equal to or smaller than the specified Arc Slow Diameter, it will travel at a reduced speed (as compared to the default cutting speed). There are two possible methods for setting this slower speed on arcs:

- Arcs Slow %. This specifies the percentage of the Cutting Speed that the speed on arcs/holes will be equal to. For instance, if the cutting speed is equal to 4000, and Arcs Slow % is equal to 50, then the actual arc speed will be (4000*50%) = 2000.

- Arcs Slow Speed. If the Arcs Slow % is equal to 0, then a set Arcs Slow Speed can be used. This value will not change depending on the main cutting speed.

Depending on which method of setting the arc speed is preferred by the user, either the Arcs Slow % (global variable 7609) or the Arcs Slow Speed (global variable 7606) are supposed to be set to 0. Utilizing both at the same time (for instance, setting Arcs Slow % to 50 and Arcs Slow Speed to 2000) may lead to unintended behaviour in certain cases. It is therefore recommended to utilize either one or the other method alone.