This is an old revision of the document!

Table of Contents

MyCNC Screen Configuration

MyCNC GUI elements

Label

Display

BDisplay

RadioDisplay

KDisplay

KSpinBox

KSpinBox2

LED Display

SVG Display

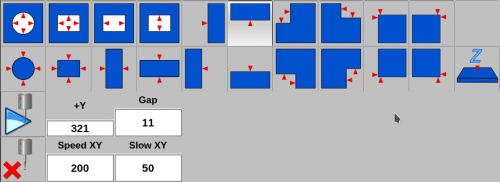

Myitems Widget

Button

A PushButton screen item can be used on myCNC screen. A typical button definition is shown below

<gitem where="main" position="160;0" width="80" height="80" image="button-refresh" action="file-refresh" type="button" />

Attributes description

- where - parent widget name the button placed to

- position - X and Y position of the button inside a parent widget

- width - button width in pixels

- height - button height in pixels

- type - type definitionof the item (should be type=“button”)

- image - a image (icon) file in SVG format for the button

- action - action for the button (which procedure will be executed if event triggered)

- event - event type the button is sensitive to. Event can be

- pressed - action is executed if the button pressed

- released - action is executed if the button released

- both - there are separate actions (“;” semicolon separated) for pressed and released events

- skinbase - besides the Image file for each button there is a common skin SVG file for all the buttons. For selected buttons skin file can be redefined with skinbase attribute. This SVG file will be used as a bottom layer for the button image.

XButton

XButton is a Push Button with built in Light indicator. Light is mostly used to show a current state of CNC controller input, output pin, CNC global variable register value etc.

A XButton XML definition example is shown below

<gitem where="x-mill" xattr="3;3;16;16;led;red;round" address="outputs" number="#OUTPUT_SPINDLE". position="720;10" width="70" height="70" image="M/button-m03" action="plc-run:M03/#5524" type="xbutton" />

Attributes description

- where - parent widget name the button placed to

- position - X and Y position of the button inside a parent widget

- width - button width in pixels

- height - button height in pixels

- type - type definitionof the item (should be type=“button”)

- image - a image (icon) file in SVG format for the button

- action - action for the button (which procedure will be executed if event triggered)

- event - event type the button is sensitive to. Event can be

- pressed - action is executed if the button pressed

- released - action is executed if the button released

- both - there are separate actions (“;” semicolon separated) for pressed and released events

- skinbase - besides the Image file for each button there is a common skin SVG file for all the buttons. For selected buttons skin file can be redefined with skinbase attribute. This SVG file will be used as a bottom layer for the button image.

- xattr - defines light positionm size and attributes - semicolon separated

- X,Y position of the led/light inside the button

- width and height of the led

- type of light (actually this field is always “led”, reserved for future options)

- shape of the standard led light. A standard shape can be “round” and “rect”

- address - defines CNC controller hardware the light attached to

- “inputs” - the light attached to input pin

- “outputs” - the light attached to output pin

- “number” - defines pin number the light attached to. A number can be assigned directly, for example

number=“0” for pin #0

number=“15” for ipn #15

or through pin definition file used in Hardware PLC - “pins.h”. In this case sign “#” and the pin name defined in “pins.h” should be instead of pin number. For example

number=“#OUTPUT_SPINDLE”

and “pins.h should contain this name definition, for example#define OUTPUT_SPINDLE 7

GLView

NCView

2D Visualization widget.

- Basic setup.

<gitem where="olicut" name="ncview" type="ncview" position="100;100" width="880" height="440" />

- Advanced setup.

<gitem where="olicut" name="ncview" type="ncview" position="100;100" width="880" height="440" singlepath="yes" bgColor="#00E0E0" ColorT0="gray:1" ColorT1="#D000D0:5" ColorT2="#D05000:5" ColorT3="red:2" ColorT4="green:2" ColorT5="#0000D0:2" />

Logview

NCList

CentringView

Rotation2View

MyCNC Actions

All button-like screen components (button, xbutton, bdisplay, kspinbox2) runs Handler procedure when “Pressed” or “Released” avent activated by mouse click or touch screen tap. The Handler defined in “action” attribute of xXML configuration item.

List of actions is shown below

| Action Name | Description |

|---|---|

| advanced-config | |

| basic-config | |

| toggle-button-coordinates | |

| toggle-button-jog-enable | |

| toggle-button-soft-limits | |

| toggle-button-mist | |

| toggle-button-flood | |

| toggle-button-spindle | |

| toggle-button-ccw-spindle-spindle | |

| toggle-item: | |

| laser-marker- |

Player actions

| Action Name | Description |

|---|---|

| player-play | |

| player-play-confirm | |

| player-play-edge | |

| player-play-edge-confirm | |

| player-jump1 | |

| player-pause | |

| player-stop | |

| player-skip-forward | |

| player-skip-forward-10 | |

| player-skip-backward | |

| player-skip-backward-10 | |

| player-skip-part-f | |

| player-skip-part-b | |

| player-nc-reset | |

| player-nc-reset-confirm | |

| player-back-to-path | |

| player-back-to-path-confirm | |

| player-play-back | |

| player-nc-tie | |

| player-play-step | |

| player-play-step-backward | |

| mdi-play | |

| mdi-open |

Jog actions

| Action Name | Description |

|---|---|

| jog-0-plus, jog-1-plus, jog-2-plus, jog-3-plus, jog-4-plus, jog-5-plus, jog-6-plus, jog-7-plus jog-8-plus | Jog Positive direction in Axis X, Y, Z, A, B, C, U, V, W |

| jog-0-minus, jog-1-minus, jog-2-minus, jog-3-minus, jog-4-minus, jog-5-minus, jog-6-minus, jog-7-minus, jog-8-minus | Jog Negative direction in Axis X,Y,Z,A,B,C,U,V,W |

| jog-0-plus-1-plus | Simultaneous two-axes Jog X+ Y+ |

| jog-0-plus-1-minus | Simultaneous two-axes Jog X+ Y- |

| jog-0-minus-1-plus | Simultaneous two-axes Jog X- Y+ |

| jog-0-minus-1-minus | Simultaneous two-axes Jog X- Y- |

| jog-overspeed-inc jog-overspeed-dec | Increment/Decrement Jog Overspeed value (%) |

| jog-overspeed-set: | Set given Jog Overspeed value (%) |

Motion Settings Actions

| Action Name | Description |

|---|---|

| step-float-inc step-float-dec | Increase/decrease Jog Step Size |

| step-size-inc step-size-dec | Increase/decrease Jog Step Size |

| motion-linear-acceleration-inc motion-linear-acceleration-dec | Increase/decrease Motion Linear Acceleration value |

| motion-linear-jog-speed-inc motion-linear-jog-speed-dec motion-linear-jogspeed-inc motion-linear-jogspeed-dec | Increase/decrease Motion Linear Jog Speed value |

| motion-jog-speed-x-inc, motion-jog-speed-x-dec, motion-jog-speed-y-inc, motion-jog-speed-y-dec, motion-jog-speed-z-inc, motion-jog-speed-z-dec, motion-jog-speed-a-inc, motion-jog-speed-a-dec, motion-jog-speed-b-inc, motion-jog-speed-b-dec, motion-jog-speed-c-inc, motion-jog-speed-c-dec, motion-jog-speed-u-inc, motion-jog-speed-u-dec, motion-jog-speed-v-inc, motion-jog-speed-v-dec, motion-jog-speed-w-inc, motion-jog-speed-w-dec, motion-jog-speed-xy-inc, motion-jog-speed-xy-dec, motion-jog-speed-xyz-inc, motion-jog-speed-xyz-dec | Increase/decrease Motion Jog Speed value for given Axis |

| motion-rapid-speed-x-inc, motion-rapid-speed-x-dec, motion-rapid-speed-y-inc, motion-rapid-speed-y-dec, motion-rapid-speed-z-inc, motion-rapid-speed-z-dec, motion-rapid-speed-a-inc, motion-rapid-speed-a-dec, motion-rapid-speed-b-inc, motion-rapid-speed-b-dec, motion-rapid-speed-c-inc, motion-rapid-speed-c-dec, motion-rapid-speed-u-inc, motion-rapid-speed-u-dec, motion-rapid-speed-v-inc, motion-rapid-speed-v-dec, motion-rapid-speed-w-inc, motion-rapid-speed-w-dec, motion-rapid-speed-xy-inc, motion-rapid-speed-xy-dec, motion-rapid-speed-xyz-inc, motion-rapid-speed-xyz-dec | Increase/decrease Motion Rapid Speed value for given Axis |

| motion-feed-speed-x-inc, motion-feed-speed-x-dec motion-feed-speed-y-inc motion-feed-speed-y-dec motion-feed-speed-z-inc motion-feed-speed-z-dec motion-feed-speed-a-inc motion-feed-speed-a-dec motion-feed-speed-b-inc motion-feed-speed-b-dec motion-rapid-speed-c-inc motion-rapid-speed-c-dec motion-rapid-speed-u-inc motion-rapid-speed-u-dec motion-rapid-speed-v-inc motion-rapid-speed-v-dec motion-rapid-speed-w-inc motion-rapid-speed-w-dec motion-rapid-speed-xy-inc motion-rapid-speed-xy-dec motion-rapid-speed-xyz-inc motion-rapid-speed-xyz-dec | Increase/decrease Motion Rapid Speed value for given Axis |

| motion-overspeed-inc motion-overspeed-dec motion-overspeed | Increase/decrease/set Motion Overspeed value (%) |

| spindle-speed-inc spindle-speed-dec spindle-speed | Increase/decrease/set Current Spindle Speed (S) for current operation. New “S” value in running g-code will overwrite Current Spindle Speed |

| spindle-speed-restore | Restore Default Spindle Speed (S) |

| spindle-overspeed-inc spindle-overspeed-dec spindle-overspeed | Increase/decrease/set Spindle Speed (S) |

Built-in Editor Actions

| Action Name | Description |

|---|---|

| editor-arrow-up | |

| editor-arrow-down | |

| editor-ncline-edit | |

| editor-ncline-insert | |

| editor-ncline-remove | |

| editor-font-inc | |

| editor-font-dec | |

| editor-numbers-toggle | |

| editor-selection-begin | |

| editor-selection-end | |

| editor-selection-remove | |

| editor-selection-insert | |

| editor-new | |

| editor-save-as | |

| editor-save |

File Manipulation Actions

| Action Name | Description |

|---|---|

| save | |

| open | |

| load-file: | |

| load-macro: | |

| file-close | |

| file-close | |

| dxf-import | |

| file-close | |

| image-import |

Visualization Actions

| Action Name | Description |

|---|---|

| zoom-in | |

| zoom-out | |

| fit-to-view | |

| zoom-in | |

| zoom-in | |

| 3dview-xy | 3D Visualization: show XY view |

| 3dview-xz | 3D Visualization: show XZ view |

| 3dview-yz | 3D Visualization: show YZ view |

| 3dview-iso | 3D Visualization: show ISO view |

| 3dview-custom: | 3D Visualization: show Custom view, defined by Alfa,Beta,Gamma angles for rotation matrix |

Widget Manipulations Actions

| Action Name | Description |

|---|---|

| show-inputbox | |

| show-widget-centring | |

| show-widget-rotation | |

| show-widget-sawcutting | |

| show-widget-diagnose | |

| show-widget-config | |

| show-widget-edit | |

| show-widget-lib | |

| show-widget-tools | |

| show-widget-lof | |

| show-widget-report | |

| show-widget-support | |

| show-widget-user | |

| show-widget-work | |

| mywidget-show: | |

| mywidget-hide: | |

| mywidget-toggle: | |

| pendant-widget-open | |

| measure-surface | |

| toggle-virtual-keyboard | |

| mywidget: |

Application Actions

| Action Name | Description |

|---|---|

| close-application | Close myCNC Control software |

| cnc-config-save | Save myCNC configuration files to disk |

Hardware Manipulation actions

| Action Name | Description |

|---|---|

| servo-pid-on | |

| servo-pid-off | |

| hw-pwm-inc | |

| hw-pwm-dec | |

| hw-dac-inc | |

| hw-dac-dec | |

| hw-direct- | |

| thc-arc-voltage-ref-inc | |

| thc-arc-voltage-ref-dec | |

| thc-jog-speed-dec | |

| thc-jog-speed-inc | |

| thc-jog-pos | |

| thc-jog-neg | |

| dev-thc-jog-pos | |

| dev-thc-jog-neg |

| toggle-widget-centring | |

| toggle-widget-rotation | |

| toggle-widget-sawcutting | |

| toggle-widget-user |

| toggle-button-flood | |

| toggle-button-coolant | |

| toggle-button-spindle | |

| toggle-button-ccw-spindle | |

| toggle-button-mist | |

| |

PLC Actions

| Action Name | Description |

|---|---|

| soft-plc-run: | |

| soft-plc-stop: | |

| *soft-plc-stop: | |

| plc-run: | |

| direct-plc: | |

| multidev-plc-run: | |

| switch-cnc-gvariable |

Job Actions

| Action Name | Description |

|---|---|

| direct-run: | |

| direct-run-confirm: | |

| radio-confirm | |

| mode-cutting-ignore | |

| mode-cutting-accept |

| mdi-save-list |

| mode-show-ruler |

| mode-show-dimension |

| mode-show-workarea |

OS/System Actions

| Action Name | Description |

|---|---|

| system-cmd | Run system command |

| application-close | Close MyCNC application |

| application-close-confirm | Run confirmation dialog to Close MyCNC application |

| application-minimize | Minimize MyCNC Application |

CNC Variables manupulation Actions

| Action Name | Description |

|---|---|

| direct-set-cnc-var | |

| cnc-variable: | |

| cnc-gvariable-dec, cnc-gvariable-inc | |

| cnc-variable-dec, cnc-variable-inc, cnc-variable-change, cnc-variable-toggle, cnc-variable-set, cnc-variable-clear, cnc-variable-vset, cnc-variable-switch | |

| cnc-vm-variable-dec, cnc-vm-variable-inc | |

| device-variable-dec, device-variable-inc |

| item-switch: | |

| run-numpad: | |

| item: | |

| load-item: | |

| cnc-nvariable- | |

| cnc-nvariable: |

| fake | Empty Handler Action. Nothing happpens if run this action |

| myitem-value-inc, myitem-value-dec | Increement/Decrement XML Item value by name |

HMI Actions

| Action Name | Description |

|---|---|

| search-nc-position | Open dialog to define line number for Run From Here command |

| file-refresh | |

| row-n-column | Open Row And Column Multiplication/Nesting Dialog |

| dialog-rotate | Open Dialog for NC-program rotation |

| mypopup-show: | Show custom defined Popup widget |

| mypopup-toggle: | Toggle custom defined Popup widget |

| mode-jog-unlimited | Switch to Unlimited Jog Mode |

| show-simple-edit | Show simple text editor window (Ver #1) |

| show-simple2-edit | Show simple text editor window (Ver #2) |

| rotate-nc-last | Rotage NC program to previously defined angle |

| cnc-cutchart-save | Save current cutting data to Cutchart |

| cnc-cutchart-load | Load cutting data for selected Cutting Mode |

| run-from-here | Run From Here command - start job file from selected line |

MyCNC screen configuration examples

Add "Servo On" - "Servo Off" buttons

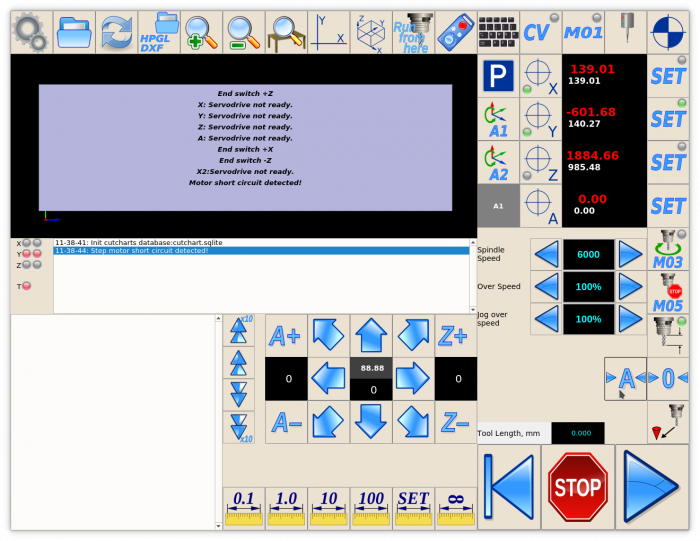

We need to add buttons for Servo On/Servo Off to 1280M5 profile

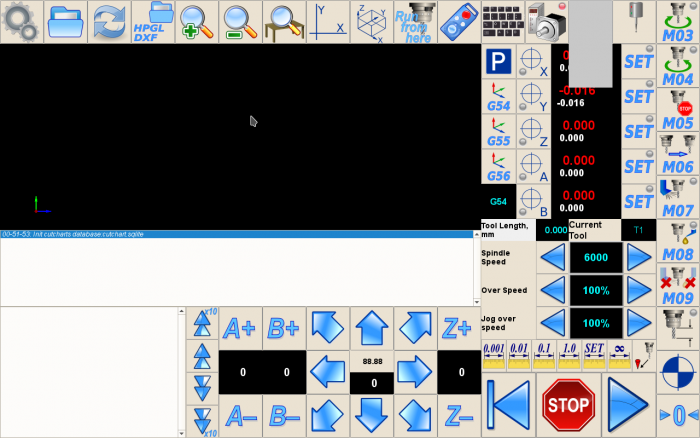

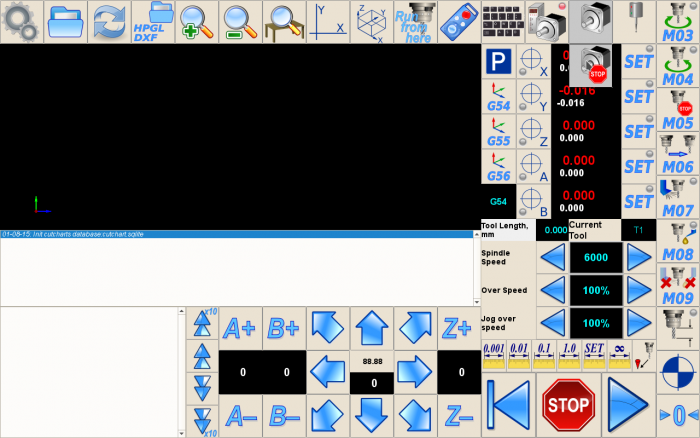

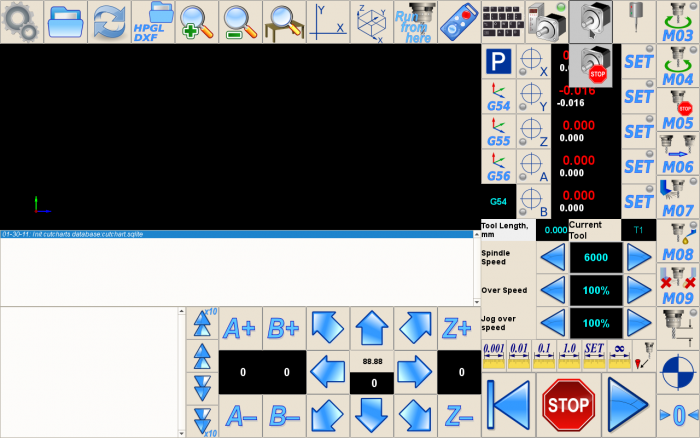

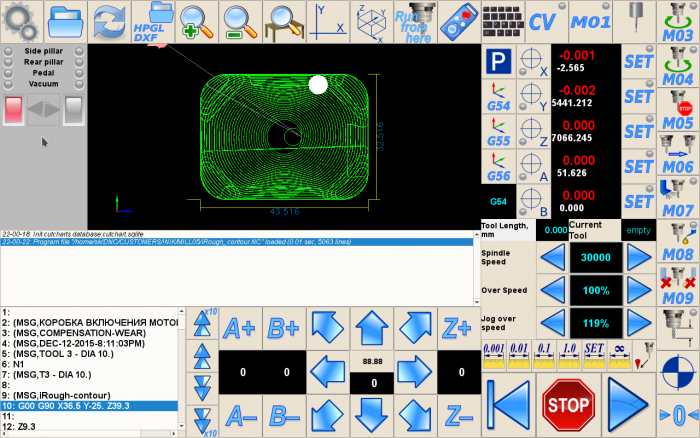

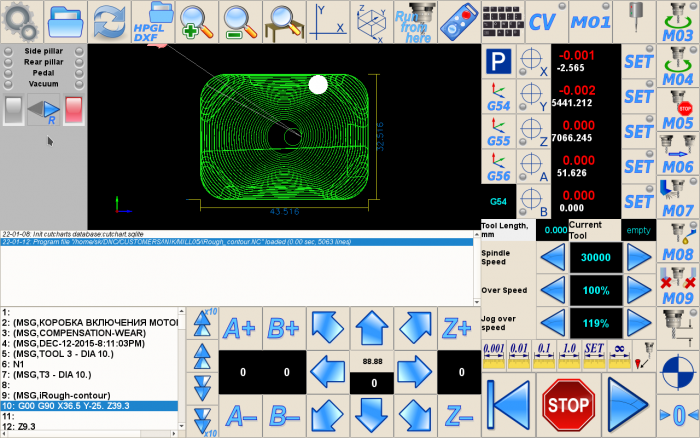

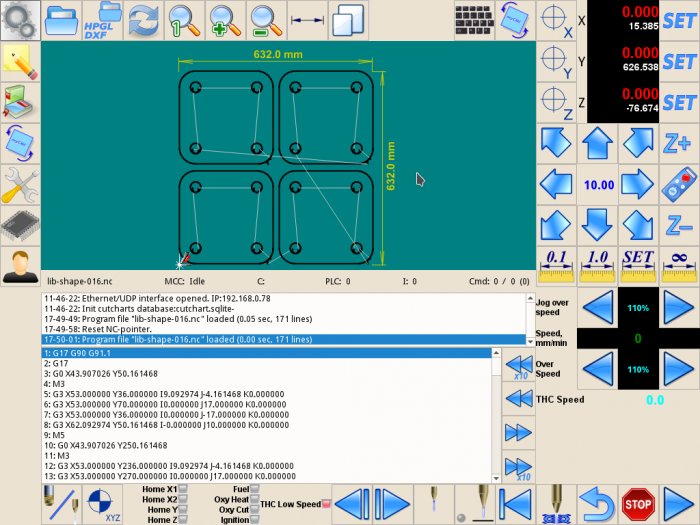

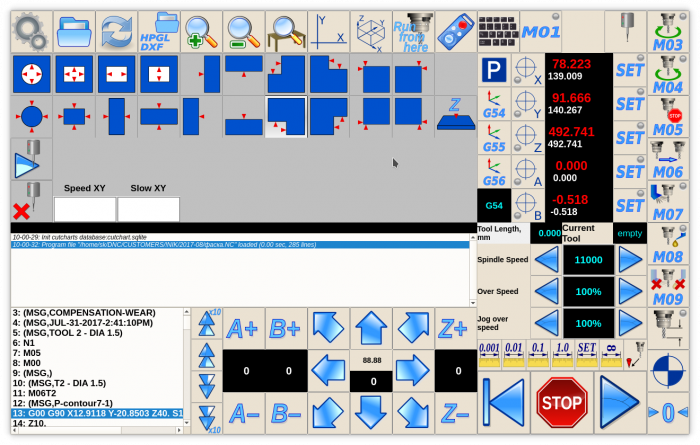

Original screen is shown below-

Put our new buttons instead of CV button

1. Find cnc-screen.xml configuration file in 1280M5 profile folder

2. Edit the file (in Midnight commander press F4 on the cnc-screen.xml file)

3. Find in the file section with CV button definition (F7, search “CV”)

Here it is-

<gitem where="magic" position="960;0" width="80" height="80" image="CV/CV" action="cnc-gvariable-toggle-5710" xattr="60;4;16;16;led;red;round" name="display-gvariable-5710" type="xbutton" />

4. Put under this button small popup window which will be a container for two buttons - Servo ON & Servo Off. Add quick-popup-layout section with popup window definition -

<quick-popup-layout> <current>popup-servo</current> <layout stretch="0" name="popup-servo" wa="80;160;right" orientation="vertical" skin="skin/metal-01"> <widget stretch="1" spacing="0" name="toolbar-servo" orientation="vertical">myitems</widget> </layout> </quick-popup-layout>

- Layout for Servo buttons named “popup-servo”, size of layout is 80×160, layout placed to the right side of the button that activates the popup (wa means “Window Attributes”).

- Layout contains a Window named “toolbar-servo”.

5. Fix CV button to show/hide popup-servo -

image=“CV/CV” action=“cnc-gvariable-toggle-5710”

image=“motor/servo-driver-wide” action=“mypopup-toggle:popup-servo”

<gitem where="magic" position="960;0" width="80" height="80" image="motor/servo-driver-wide" action="mypopup-toggle:popup-servo" xattr="60;4;16;16;led;red;round" name="display-gvariable-5710" type="xbutton" />

6. Save cnc-screen.xml, restart the software and press new button wit Servo driver. Small popup grey colour window will be shown on the right side of the button.

7. Add two buttons definition in the popup window

<gitem where="toolbar-servo" image="motor/motor-start" action="plc-run:M62/3" height="80" event="pressed-delay-1000" type="button"/> <gitem where="toolbar-servo" image="motor/motor-stop" action="plc-run:M63/3" height="80" type="button"/>

to prevent accidental servo driver activation add 1 sec delay for start button -

event="pressed-delay-1000"

action function will be started only if the button press and hold for 1 sec (1000 msec). On button will ON relay #3 (M62.plc procedure) Off button will Off relay #3 (M63.plc procedure)

For more complicated configurations special PLC procedure can be written to handle Servo ON/OFF (for example turn On servo power, wait some time and then check servo Fault/Alarm inputs before turn On Servo On)

Result should be like this -

button & xbutton types

Difference between button and xbutton push-button types easy to see if compare “Servo” button that shows/hide popup window and “Servo-On”/“Servo-Off” buttons. Main “Servo” button contains LED display. XButton is simple Push button with added LED display on the top. Led parameters are given in attribute xattr.

xattr="60;4;16;16;led;red;round" name="display-gvariable-5710" type="xbutton" />

In xattr programmed start x, y positions of Led inside the button, width and height of Led, defines led type, led colour (red, green, blue, yellow) and led shape (round, square).

Custome defines skin from SVG file is possible too and will be described in other examples.

Attribute name=“display-gvariable-5710” setup LED display to show current state of CNC Global variable #5710 (0 - Led is OFF, 1 or more - LED is ON)

Attributes address=“outputs” number=“3” setup LED display to show current state of output pin #3

To complete this example change led to show output pin #3 to show current servo state and resize the led -

<gitem where="magic" position="960;0" width="80" height="80" image="motor/servo-driver-wide" action="mypopup-toggle:popup-servo" xattr="56;4;20;20;led;green;round" address="outputs" number="3" type="xbutton" />

Add "Servo On" - "Servo Off" buttons (Version 2)

Just another way to add 2 buttons widget containers with 2 buttons. The same 1280M5 profile

Original screen is shown below-

Put our new buttons instead of CV button

1. Find cnc-screen.xml configuration file in 1280M5 profile folder

2. Edit the file (in Midnight commander press F4 on the cnc-screen.xml file)

3. Find in the file section with CV button definition (F7, search “CV”)

Here it is-

<gitem where="magic" position="960;0" width="80" height="80" image="CV/CV" action="cnc-gvariable-toggle-5710" xattr="60;4;16;16;led;red;round" name="display-gvariable-5710" type="xbutton" />

4. Put under this button small popup window which will be a container for two buttons - Servo ON & Servo Off. Add mywidget item - custom small widget with given attributes -

<gitem where="magic" position="1120;80" height="160" width="80" type="myitems" name="toolbar-servo" bgColor="#d0d0d0" hidden="1" />

widget name: toolbar-servo

widget size: 80×160 exactly to fit 2 80×80 buttons in

built-in led to show output#0 state

5. Fix CV button to show/hide popup-servo -

image=“CV/CV” action=“cnc-gvariable-toggle-5710”

image=“motor/servo-driver” action=“mywidget-toggle:toolbar-servo”

<gitem where="magic" width="80" height="80" position="1120;0" image="motor/servo-driver" action="mywidget-toggle:toolbar-servo" xattr="56;4;20;20;led;green;round" address="outputs" number="0" type="xbutton" ></gitem>

6. Save cnc-screen.xml, restart the software and press the new button with Servo driver. Small popup grey colour window will be shown on the right side of the button.

7. Add two buttons definition in the popup window. Definition is very similar to previous example but need to add button position attribute inside widget and button width/height attributes.

<gitem where="toolbar-servo" position="0;0" width="80" height="80" image="motor/motor-start" action="servo-pid-on" event="pressed-delay-1000" type="button" /> <gitem where="toolbar-servo" position="0;80" width="80" height="80" image="motor/motor-stop" action="servo-pid-off" type="button" />

to prevent accidental servo driver activation add 1 sec delay for start button -

event="pressed-delay-1000"

action function will be started only if the button press and hold for 1 sec (1000 msec). On button will run Servo-Pid-ON procedure Off button will run Servo-Pid-Off procedure

Result should be like this -

Add Window with some LEDs display

We need to add to the main screen a window with 8 led displays and some text labels to show the current state of inputs & outputs. We take 1280M5 profile as a base

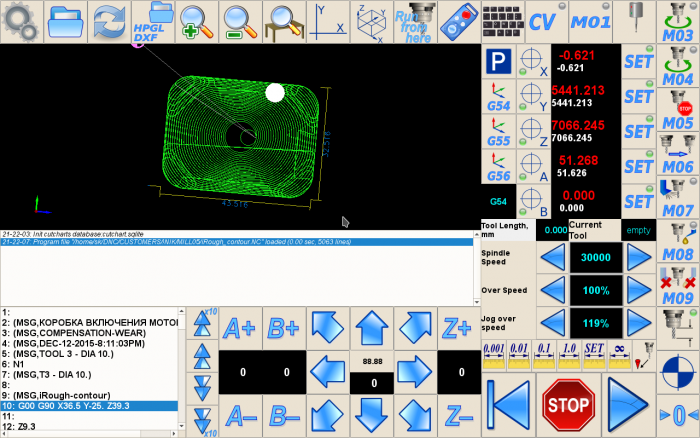

Original screen is -

Make the visualisation widget a little narrow and put the new window to the left side from visualization. Find “glview” section in cnc-screen.xml and fix from:

<gitem where="magic" position="0;80" width="880" height="340" bgColor="0xff353535" name="glview" type="glview" />

to:

<gitem where="magic" position="160;80" width="820" height="340" bgColor="#ff353535" name="glview" type="glview" /> <gitem where="magic" position="0;80" width="160" height="340" bgColor="#ffbbbbbb" name="led-panel" type="myitems" />

Result is -

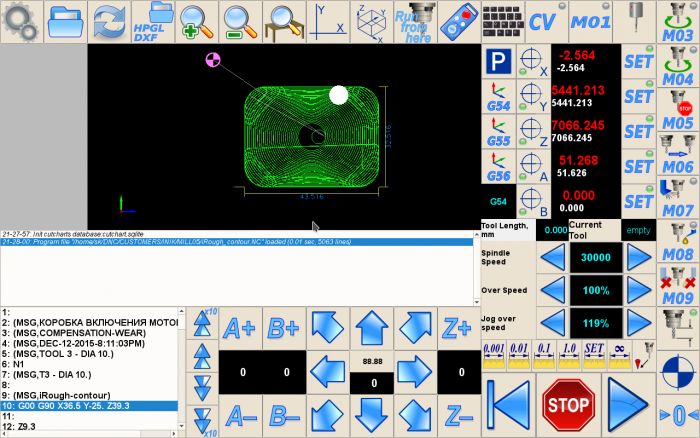

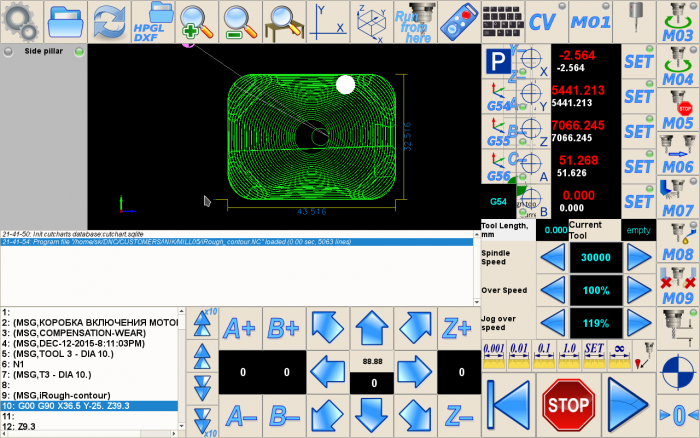

Add 1st line label and leds from laft and right sides:

<gitem inversion="no" where="led-panel" position="5;5" width="20" displayWidth="20" height="20" address="outputs" number="11" shape="round" color="green" type="led" /> <gitem inversion="no" where="led-panel" position="25;5" width="130" labelWidth="110" displayWidth="20" height="20" labelAlignment="hcenter" labelFontSize="14" address="outputs" number="14" shape="round" color="green" type="led"> <message>Side pillar</message> <message_ru>Боковой упор</message_ru> </gitem>

where=“led-panel” - LEDs will be added to window named “led-panel” which was added before

address=“outputs” - Leds will show state of Outputs

<gitem inversion=“no” where=“led-panel” position=“5;5” width=“20” displayWidth=“20” height=“20” address=“outputs” number=“11” shape=“round” color=“green” type=“led” /> - fisrt (left) led is single, no text label assigned

<message_ru>Боковой упор</message_ru> - second (right) led assosiated with text label

position=“5;5” - led is placed to position inside parent widget

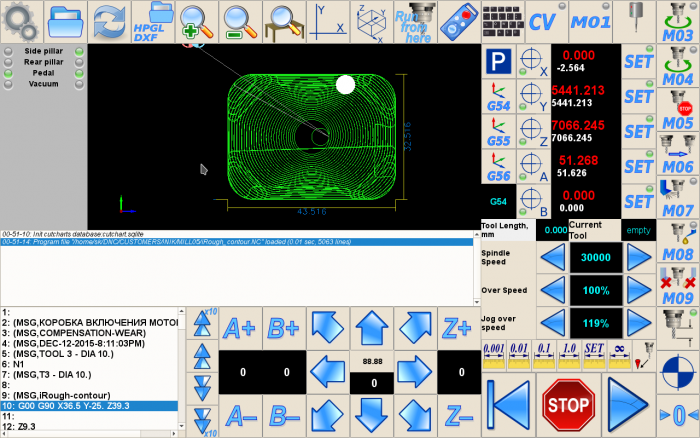

Add some more LEDs to the widget. Complete code for the widget is -

<gitem where="magic" position="0;80" width="160" height="340" bgColor="#ffbbbbbb" name="led-panel" type="myitems" /> <gitem inversion="no" where="led-panel" position="5;5" width="20" displayWidth="20" height="20" address="outputs" number="11" shape="round" color="green" type="led" /> <gitem inversion="no" where="led-panel" position="25;5" width="130" labelWidth="110" displayWidth="20" height="20" address="outputs" number="14" labelAlignment="hcenter" labelFontSize="14" shape="round" color="green" type="led"> <message>Side pillar</message> <message_ru>Боковой упор</message_ru> </gitem> <gitem inversion="no" where="led-panel" position="5;25" width="20" displayWidth="20" height="20" address="outputs" number="22" shape="round" color="green" type="led" /> <gitem inversion="no" where="led-panel" position="25;25" width="130" labelWidth="110" displayWidth="20" height="20" address="outputs" number="23" labelAlignment="hcenter" labelFontSize="14" shape="round" color="green" type="led"> <message>Rear pillar</message> <message_ru>Задний упор</message_ru> </gitem> <gitem inversion="no" where="led-panel" position="5;45" width="20" displayWidth="20" height="20" address="inputs" number="13" shape="round" color="green" type="led" /> <gitem inversion="no" where="led-panel" position="25;45" width="130" labelWidth="110" displayWidth="20" height="20" address="inputs" number="14" labelAlignment="hcenter" labelFontSize="14"shape="round" color="green" type="led"> <message>Pedal</message> <message_ru>Педаль</message_ru> </gitem> <gitem inversion="no" where="led-panel" position="5;65" width="20" displayWidth="20" height="20" address="outputs" number="10" shape="round" color="green" type="led" /> <gitem inversion="no" where="led-panel" position="25;65" width="130" labelWidth="110" displayWidth="20" height="20" address="outputs" number="15" labelAlignment="hcenter" labelFontSize="14" shape="round" color="green" type="led"> <message>Vacuum</message> <message_ru>Присоски</message_ru> </gitem>

Result is -

Add Button with led display, that toggles Global Variable value and shows the current state

For described example machine runs the same g-code on left and right sides of the machine table. To increase a performance operator remove ready parts and install a new blank on one side of the table while the machine cuts new parts on another side.

Global variable #500 contains Current active side machine works (or going to work) with. Variable value-

0 - means machine works (or will start to work) with the left side,

1 - means machine works on the right side.

We add a button to toggle current side. We add on-button indication and add LED displays to show current working side.

Button definition is shown below -

<gitem where="led-panel" type="xbutton" position="50;90" width="60" height="60" image="left-right" action="direct-run:G90 G10 L186 P500 Q1" /> </code Led displays to the left and right sides from button - <code xml> <gitem inversion="no" where="led-panel" position="5;90" width="40" height="60" name="display-cnc-gvariable-500" shape="square" color="red" type="led" /> <gitem inversion="yes" where="led-panel" position="115;90" width="40" height="60" name="display-cnc-gvariable-500" shape="square" color="red" type="led" />

Result is -

To add “Current Side” indication on the button -

change type <del>"button"</del> "xbutton add xattr="xattr="0;0;60;60;led;green;round" add name="display-cnc-gvariable-500" to show current state of Variable #500 add image files array - images="--left;--right"

images to show Variable state have the same size as the button itself, so image –left or –right will be drawn on the top of the button image.

Images for button base, “the left state” and “the right state” are

code for button definition is -

<gitem where="led-panel" position="50;90" width="60" displayWidth="60" height="60" image="left-right" type="xbutton" action="direct-run:G90 G10 L186 P500 Q1" images="--left-right;left--right" name="display-cnc-gvariable-500" xattr="0;0;60;60;led;green;round"/>

Result screen is -

Add Buttons with LED display that runs PLC procedures and shows Output pin state

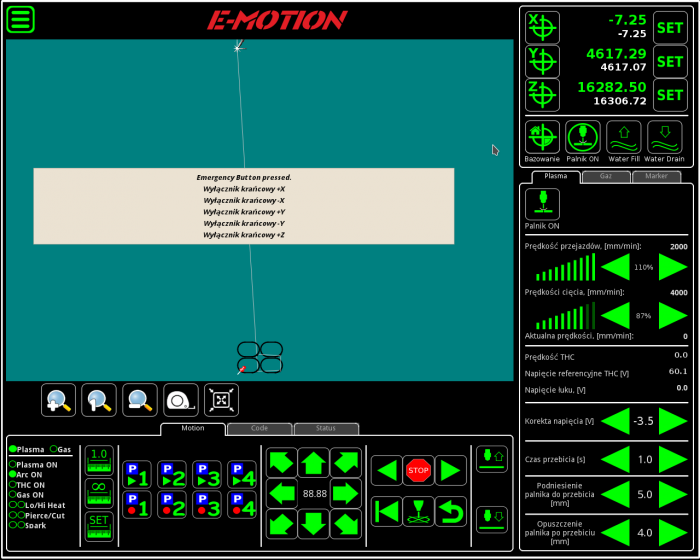

We need to add 2 buttons on GUI main screen to fill up and drain water from plasma cutting machine water table.

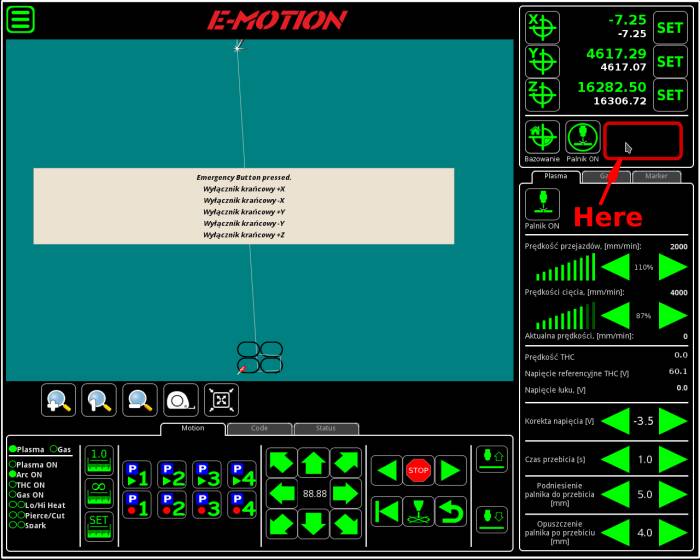

Need to add the button to the right from Palnik ON button -

Goto cnc-screen.xml in profile folder, find “Palnik ON” line. Here it is: definition of Palnik ON button and a a text label under it -

<gitem where="ecocut-coordinates" position="80;205" width="60" height="60" image="Ecocut/2a;Ecocut/1a" action="cnc-mode-cutting-ignore" type="toggle-switch" /> <gitem where="ecocut-coordinates" position="80;265" width="60" height="20" type="label" fgColor="white" labelFgColor="white" labelFontFamily="sans-serif" labelFontSize="12" fontSize="12" fontStyle="bold" labelAlignment="vcenter;hcenter"> <message>Test Plasma</message> <message_ru>Поджиг</message_ru> <message_pl>Palnik ON</message_pl> </gitem>

where=“ecocut-coordinates” - widget where button & label are placed

position=“80;205” width=“60” height=“60” - position, width and height of the button

We need to add 2 buttons just after it -

<gitem where="ecocut-coordinates" position="150;205" width="60" height="60" image="Ecocut/water-up" action="direct-plc:M240/1" type="button" /> <gitem where="ecocut-coordinates" position="145;265" width="70" height="20" type="label" fgColor="white" labelFgColor="white" labelFontFamily="sans-serif" labelFontSize="12" fontSize="12" fontStyle="bold" labelAlignment="vcenter;hcenter" > <message>Water Fill</message> <message_pl>Water Fill</message_pl> </gitem> <gitem where="ecocut-coordinates" position="220;205" width="60" height="60" image="Ecocut/water-down" action="direct-plc:M240/0" type="button" /> <gitem where="ecocut-coordinates" position="215;265" width="70" height="20" type="label" fgColor="white" labelFgColor="white" labelFontFamily="sans-serif" labelFontSize="12" fontSize="12" fontStyle="bold" labelAlignment="vcenter;hcenter" > <message>Water Drain</message> <message_pl>Water Drain</message_pl> </gitem>

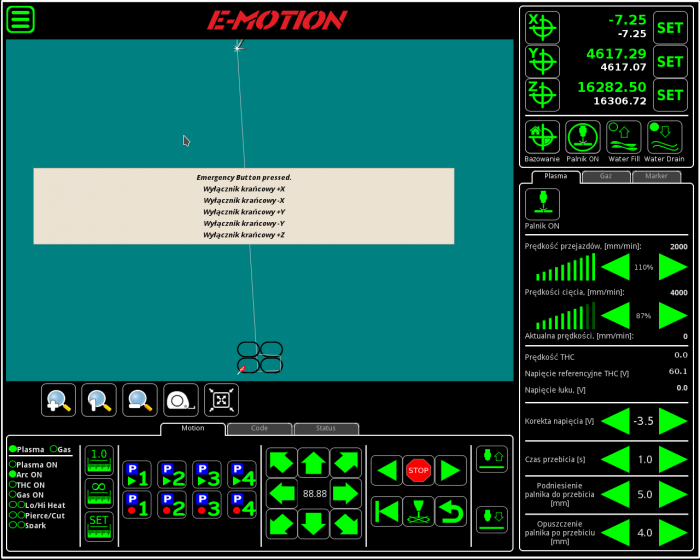

Result is -

Out pin #13 controls Water Fill, Out pin #12 controls Water Drain

Add LEDs display to the buttons -

1. Change type from “button” to “xbutton” 2. Add xatrr attribute to buttons definition with LEDs position, width, height, colour and shape 3. Add to button definition attribute address=“outputs” and number=“12” (or number=“13”) to show output pin state

<gitem where="ecocut-coordinates" position="150;205" width="60" height="60" image="Ecocut/water-up" action="direct-plc:M240/1" type="xbutton" xattr="4;4;16;16;led;green;round" address="outputs" number="13"/> <gitem where="ecocut-coordinates" position="220;205" width="60" height="60" image="Ecocut/water-down" action="direct-plc:M240/0" type="xbutton" xattr="4;4;16;16;led;green;round" address="outputs" number="12" />

Result is -

To control Water Fill/Drain PLC procedure M240 with parameter “1” (to Fill) or “0” (to Drain) is used. PLC procedure M240 is described Here

Add display to show current PLC status for Gas Cutting

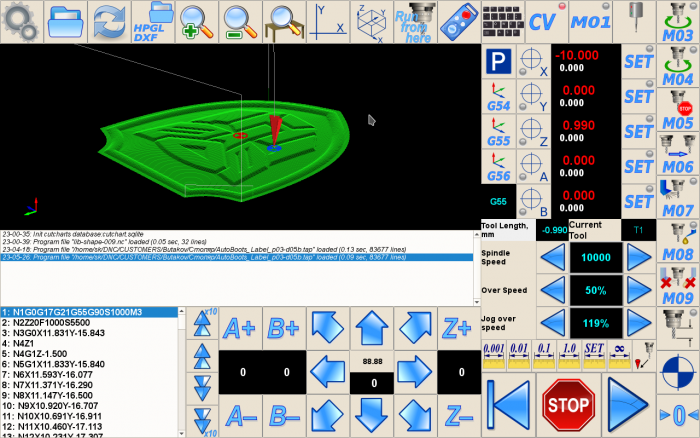

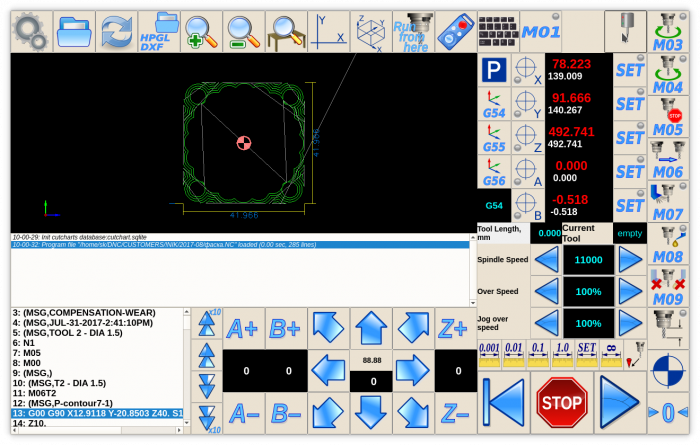

We will fix 1024G profile. The main screen of the profile is shown below.

Put PLC process display to the top of the empty area next to “THC Speed” display.

To add the display -

- find and open to edit “cnc-screen.xml” file in profile folder

- find reference “THC Speed” display -

<gitem fgColor="cyan" where="w-operate" labelFontStyle="bold" format="%5.1f" K="1." height="30" type="display" deviation="0.01" name="display-gvariable-5493" bgColor="transparent" displayWidth="140" labelWidth="100" fontStyle="bold" fontSize="20" orientation="horizontal"> <message>THC Speed</message> <message_ru>Z Слежение</message_ru> </gitem></code * Add new display (easy way to copy-paste "THC Speed" display and edit it. * Remove "name", "K" attributes * Add "address" attribute to organize process display - <code>address="plc-proc"

- Change type -

type="radio-display"

- Edit “format” attribute -

format="No Cutting=0;Ignition=50;PreHeat=51;Cutting=60"

- Translate text inside format attribute if need local language messages -

format="Ожиидание=0;Поджиг=50;Подогрев=51;Резка=60

- Edit bgColor, fgColor, fontSize attributes to get nice looking display

A complete code -

<gitem fgColor="cyan" where="w-operate" labelFontStyle="bold" type="radio-display" address="plc-proc" format="Ожидание=0;Поджиг=50;Подогрев=51;Резка=60" height="30" displayWidth="140" labelWidth="100" bgColor="black" fontStyle="bold" fontSize="16" orientation="horizontal"> <message>Proc</message> <message_ru>Процесс</message_ru> </gitem>

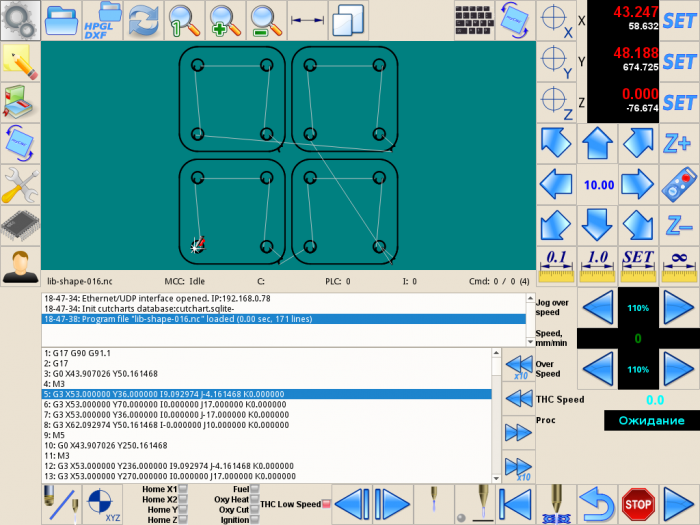

Screen result is -

Add "Move A to 0" button to run macro with confirmation

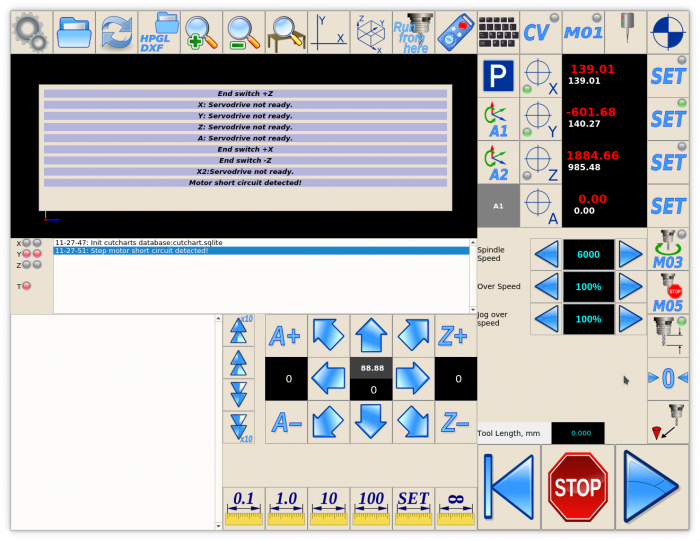

For 3 axes machine we have a button >0< to moves machine to work 0 position.

For machines with rotational axes it is convenient to have similar button to move rotational axis A to work 0.

For 3 axes machine we have a button >0< to moves machine to work 0 position.

For machines with rotational axes it is convenient to have similar button to move rotational axis A to work 0.

We add this button to the main screen on the left of >0< button. Here is Move To 0 definition -

<gitem type="button" where="magic" image="parking/move-to-0" action="direct-run-confirm:M333" position="1200;640" width="80" height="80"> <message-confirm>Move to Work (0,0,Tool Lift) position (macro M333). Are you sure?</message-confirm> <message-confirm_ru>Переместить в положение (0,0, Tool Lift) (макро M333)?</message-confirm_ru> </gitem>

Add on the left Move To A definition -

<gitem type="button" where="magic" image="parking/move-to-A" action="direct-run-confirm:M335" position="1120;640" width="80" height="80"> <message-confirm>Move to A=0 position (macro M335). Are you sure?</message-confirm> <message-confirm_ru>Вернуть в А=0 (макро M335)?</message-confirm_ru> </gitem>

- type=“button” - Button definition

- where=“magic” - Name of Parent Widget

- image=“parking/move-to-A” - Button skin image filename (SVG format, folder relative to /myCNC/art/buttons-no-theme/)

- action=“direct-run-confirm:M335” - What to do if button pressed -

- direct-run-confirm: - Open Message box to confirm, then

- run G-code sequence (”;“ is used as separator of g-code blocks)

- position=“1120;640” width=“80” height=“80” - button position on Parent Widget, width and height of button

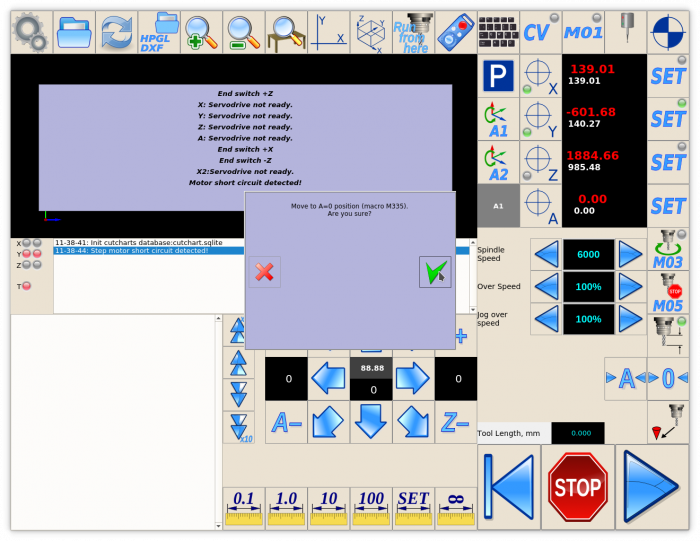

- <message-confirm>Move to A=0 position (macro M335). Are you sure?</message-confirm> - message to show in Message Box

- <message-confirm_ru>Вернуть в А=0 (макро M335)?</message-confirm_ru> - message to show for Russian language

Message Box when Move To A button pressed

Message Box when Move To A button pressed

If button OK pressed on Message Box, g-code line M335 (which is macro actually) will be executed to move A axs to zero.

Add Centring Widget on main GUI screen

myCNC software has Centring widget to work with probing sensor and find internal and external centers, edges, corners on parts.

Fig. Centring Widget

Fig. Centring Widget

There is just 1 line to configure Centring Widget in cnc-screen.xml configuration file.

<gitem type="centringview" where="magic" bsize="80" position="0;80" width="880" height="320" hidden="1" bgColor="#c0c0c0">centringview</gitem>

- type=“centringview” - Centring Widget definition

- where=“magic” - name of Parent Widget

- bsize=“80” - size of buttons

- position=“0;80” width=“880” height=“320” - Position of Centring Widget on the Parent WIdget, width and height of Centring Widget

- hidden=“1” - Centring Widget is hidden on the start of GUI

- bgColor=”#c0c0c0“ - Backgroundcolor of Centring Widget

Centring Widget takes a lot of space on the GUI screen, so it's convenient to have it hidden while normal work and show the widget only when work with Probe sensor. To show/hide Centring Widget usually used on-screen button.

<gitem type="button" image="probing/centring-unit" action="toggle-widget-centring" where="magic" position="1120;0" width="80" height="80" />

- type=“button” - Button definition

- image=“probing/centring-unit” - image for the button skin (in SVG format, relative to images folder ”/myCNC/art/buttons-no-theme/

- action=“toggle-widget-centring” - Action definition for pressing the button - Show/Hide Centring Widget

- where=“magic” - name of Parent Widget

- position=“1120;0” width=“80” height=“80” - Button position on the Parent Widget, width and height on the button in pixels