This is an old revision of the document!

Table of Contents

Rotary encoder connection and setup

There are 2 types or rotary encoders widely used in Pendants and operator panels -

- Simple rotary encoder based on 2 switches. This type of encoders usually generate 10-40 pulses per revolution (PPR) and used as fancy style “endless multi-turn potentiometer”.

Both types can be connected to myCNC controller and used in operator control panel.

EN11 rotary encoder connection

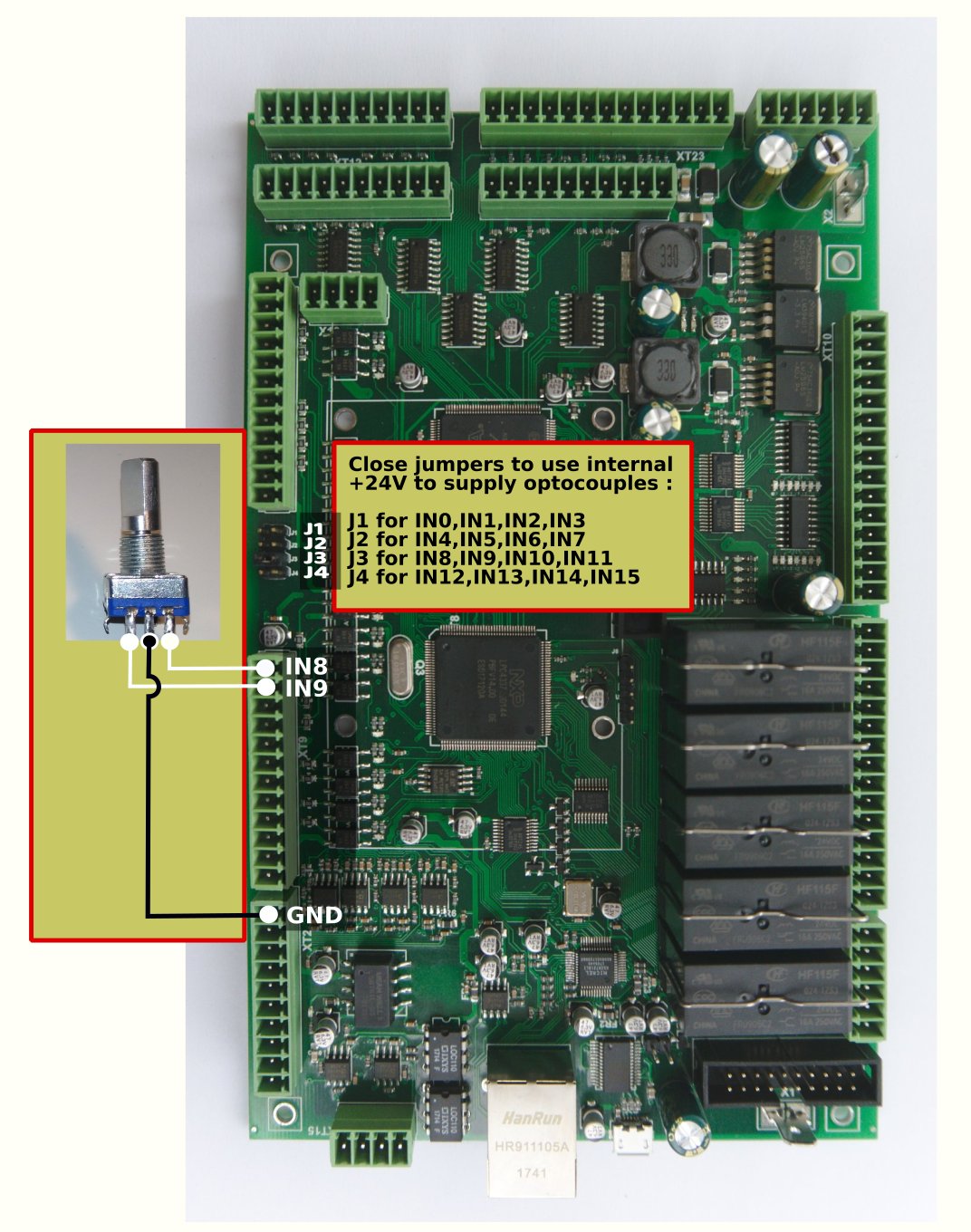

Encoders can be connected to galvanic isolated binary inputs. 2 Inputs are used to connect each encoder.

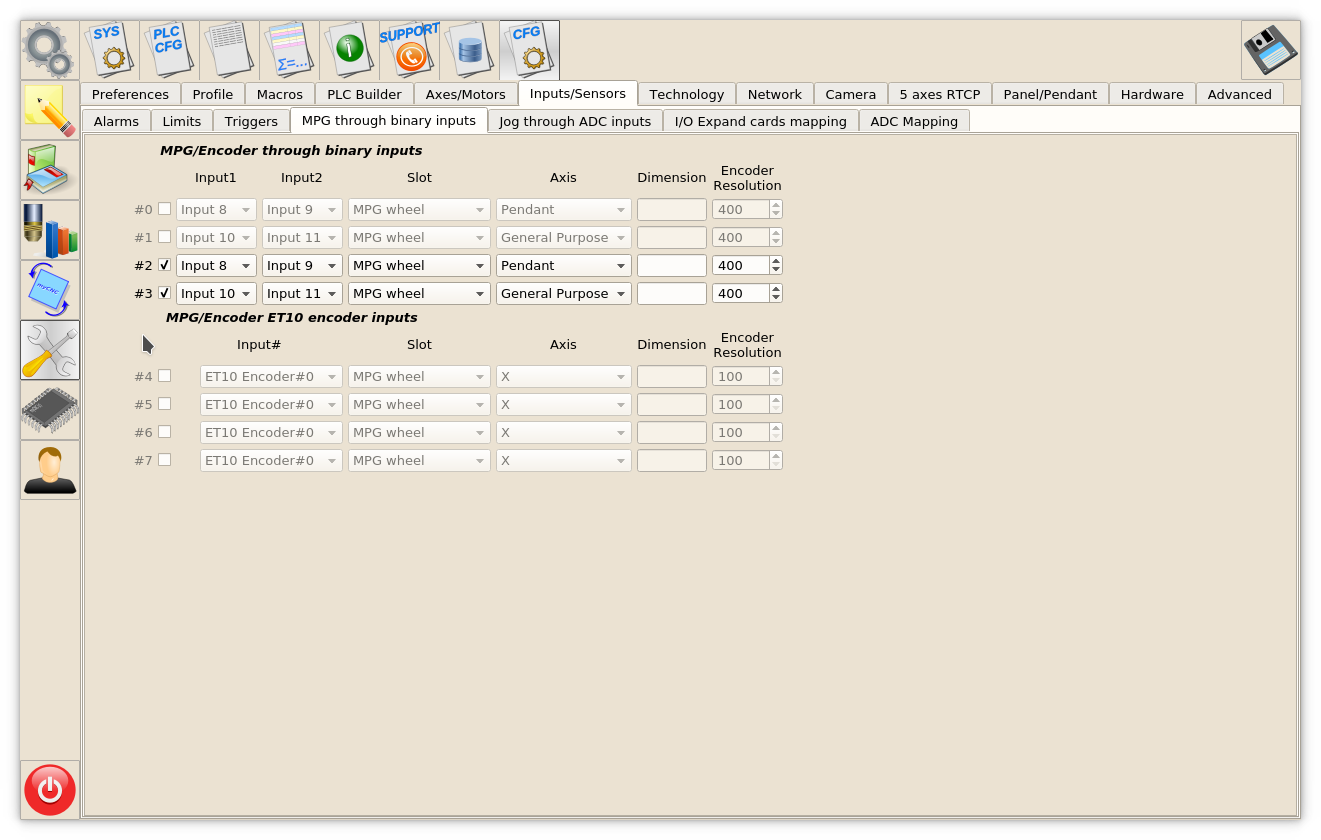

Encoder should be setup in Cfg→Inputs/Sensors→MPG through binary inputs configuration dialog.

myCNC controllers support up to 4 software encoders defined through binary inputs.

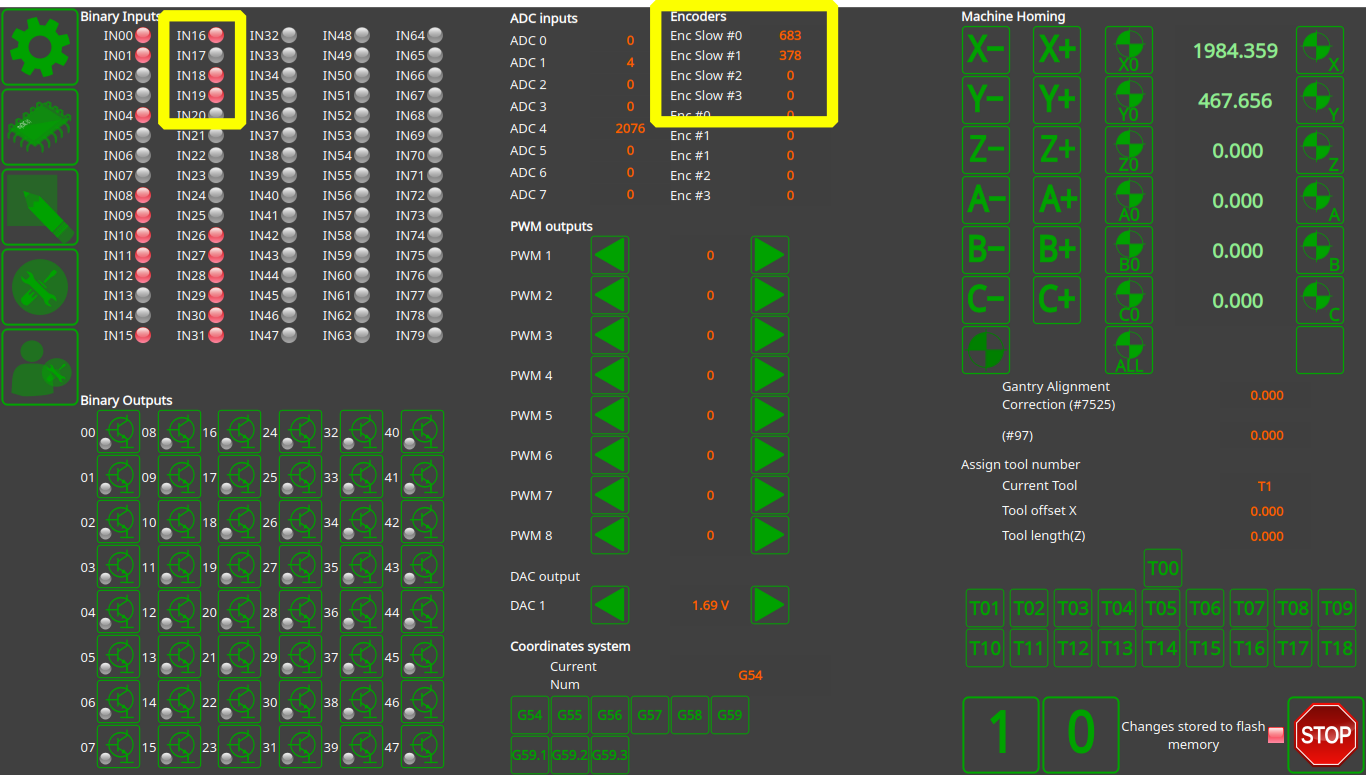

ET7 controller slow encoders setup

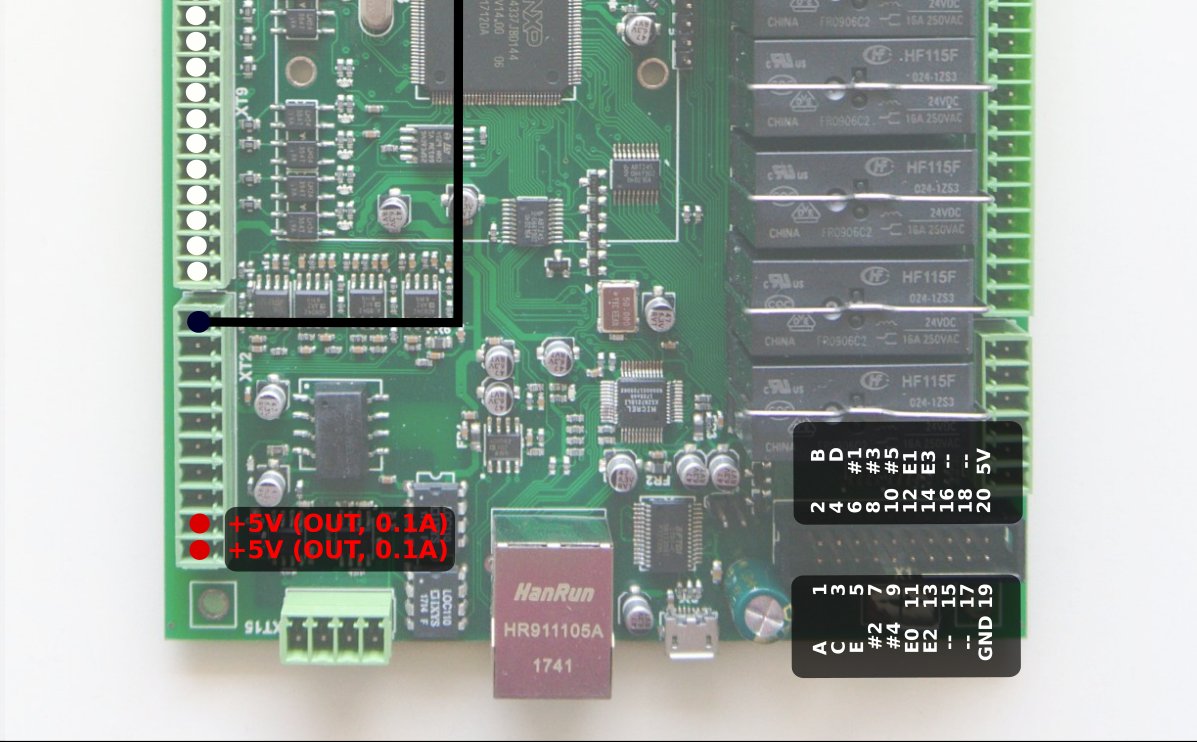

However myCNC-ET7 control board has 2 encoders (Encoder #0, #1) defined permanently. These encoders are supposed to be installed on ET7-Key keyboard panel and connected to the 20-pin X4 connector on ET7 control board. It's possible to use external encoders without ET7-key panel board and connect it directly to X4 pins 11,12,13,14 and 19. See the table below.

ET7 connector X4 pinout table

| X4 connector to External 25-keys keyboard | ||

|---|---|---|

| Pin# | Name | Comments |

| 11 | E#0 | Binary input #16, En#0 A |

| 12 | E#1 | Binary input #17, En#0 B |

| 13 | E#2 | Binary input #18, En#1 A |

| 14 | E#3 | Binary input #19, En#1 B |

| 19 | GND |

These pins are actually Binary inputs #16, #17, #18, #19 which are permanently configured as Encoder#0 and Encoder#1 in myCNC-ET7 controller firmware. This is the reason Slow Encoders #0, #1 configuration for ET7 controller in myCNC software is ignored and can be skipped. However, Encoder #2, Encoder#3 can be attached to any or binary inputs and configured accordingly.

For all other control boards ET6, ET10, ET15 all slow encoders configuration #0 - #3 is active and can be used by users.

Rotary encoders setup example is shown on a picture below

There are 2 encoders attached on Inputs #8,9,10,11 and set up in the dialog.

- Encoder #2 is attached to inputs #8 and #9 and used as a Pendant MPG/Wheel.

- Encoder #3 is attached to inputs #10 and #11 and used as a general purpose encoder.

For ET7 controller Encoders #0, #1 connected to X4 connector pins 11-14 (or through ET7-KEY keyboard) are configured despite on disabled settings.

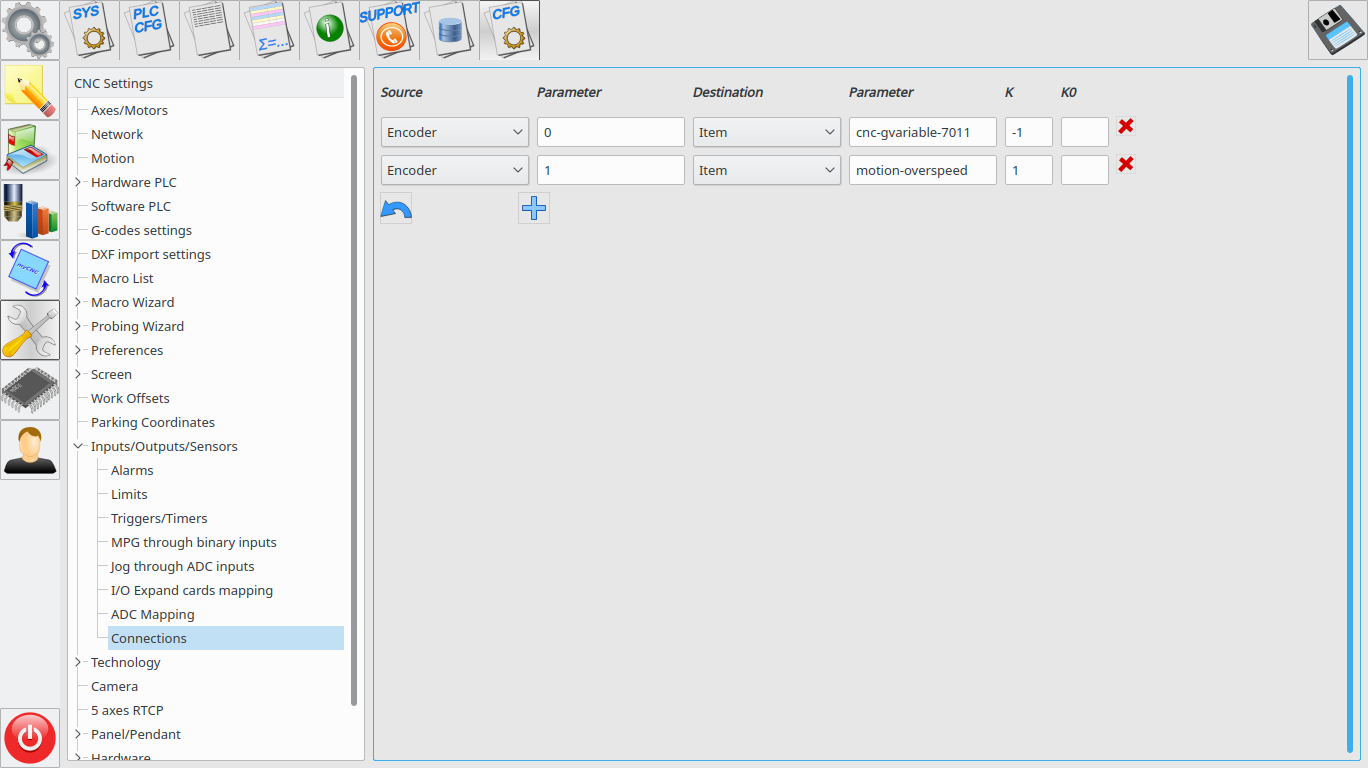

Encoder connection setup through configuration dialog.

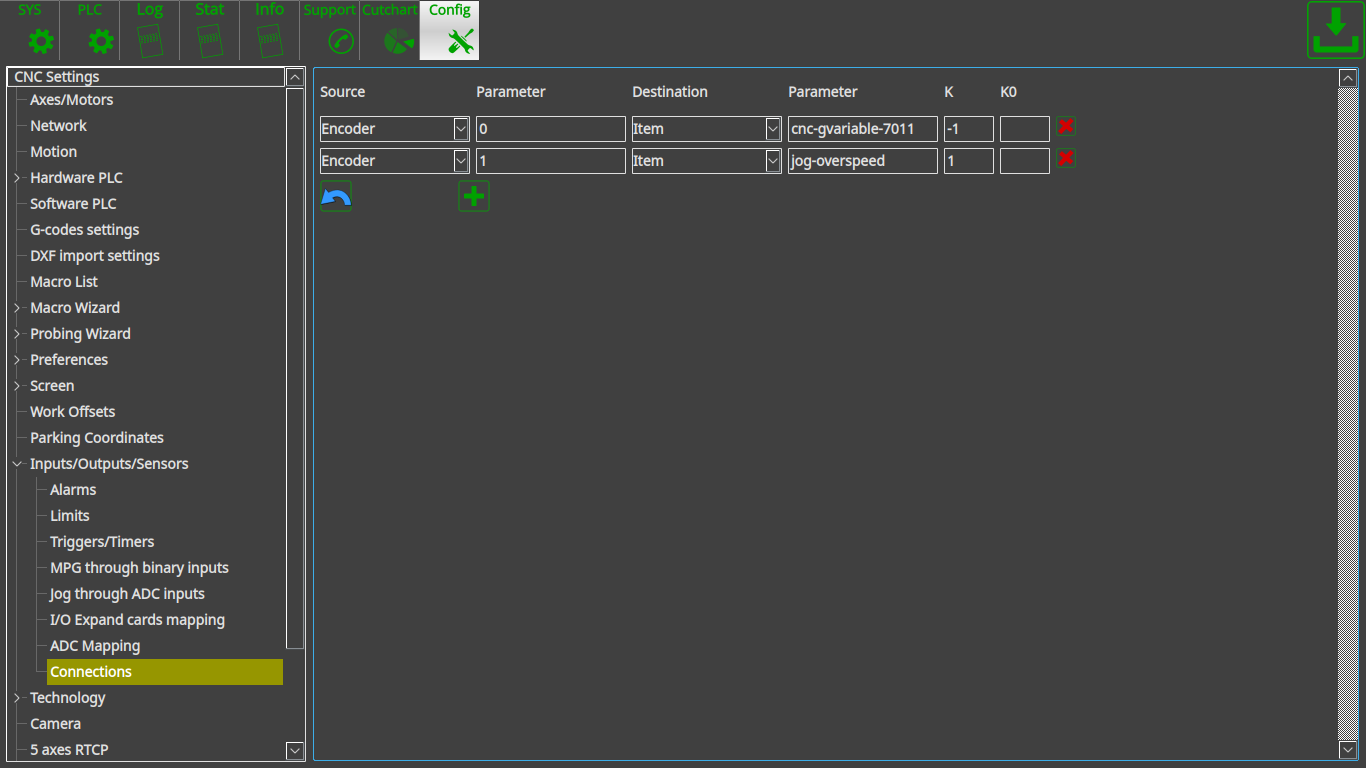

A general purpose encoder can be connected to one of the system variables for convenient control.

There is configuration dialog to set up connection between slow encoder values and CNC parameters.

- Source - source of connection - can be Encoder, ADC, input/output pin, PWM, global variable or other parameters

- Source/Parameter - address of source. It can be Encoder number, input pin number, global variable address etc

- Destination - destination connection

- Destination/Parameter - destination address

- K - destination ratio. For example, Spindle speed will be increased 100RPM every encoder click if “K=100”.

On-panel rotary encoders mostly used to control on-the-fly

- Overspeed [%]

- THC Arc reference voltage [V] (actually cutting height)

- Spindle speed

A rotary encoder should be connected to XML configuration Item “motion-overspeed” to control Overspeed [%]

Global variable register 7011 is used to change on-the-fly Cutting height (THC Arc reference voltage)

To change Spindle speed XML Item “spindle-default-speed” can be used.

| Name | Destination type | Parameter |

|---|---|---|

| Overspeed [%] | Item | motion-overspeed |

| THC Arc voltage reference | Item | cnc-gvariable-7011 |

| Spindle Speed | Item | spindle-default-speed |

Obsolete method to establish connection through "cnc-variables.xml" configuration file.

(this method was used before the dialog described above was issued)

The connection assignment can be written directly in cnc-variables.xml configuration file . For example

<value name="cnc-connection-item-002" source="encoder:3" dest="item:motion-overspeed" >0</value>

- source=“encoder:3” - encoder #3 defined as a source

- dest=“item:motion-overspeed” - motion-overspeed defined as destination

Encoder #3 connected to motion-overspeed variable. Overspeed (%) value will be changed by rotating the encoder.

<value name="cnc-connection-item-003" source="encoder:2" dest="item:cnc-gvariable-7012">0</value>

- source=“encoder:2” - encoder #2 defined as a source

- dest=“item:cnc-gvariable-7012” - Global variable for THC Arc Voltage Adjustment value is a destination for the connection

Encoder #2 connected to THC Arc voltage adjustment. Adjustment Arc value will be changed “+1” or “-1” every encoder click.