Table of Contents

THC Troubleshooting

This troubleshooting guide is part of a larger Torch Height Control manual - please consult the full manual for a detailed description of the THC setup.

Check the ADC channel number

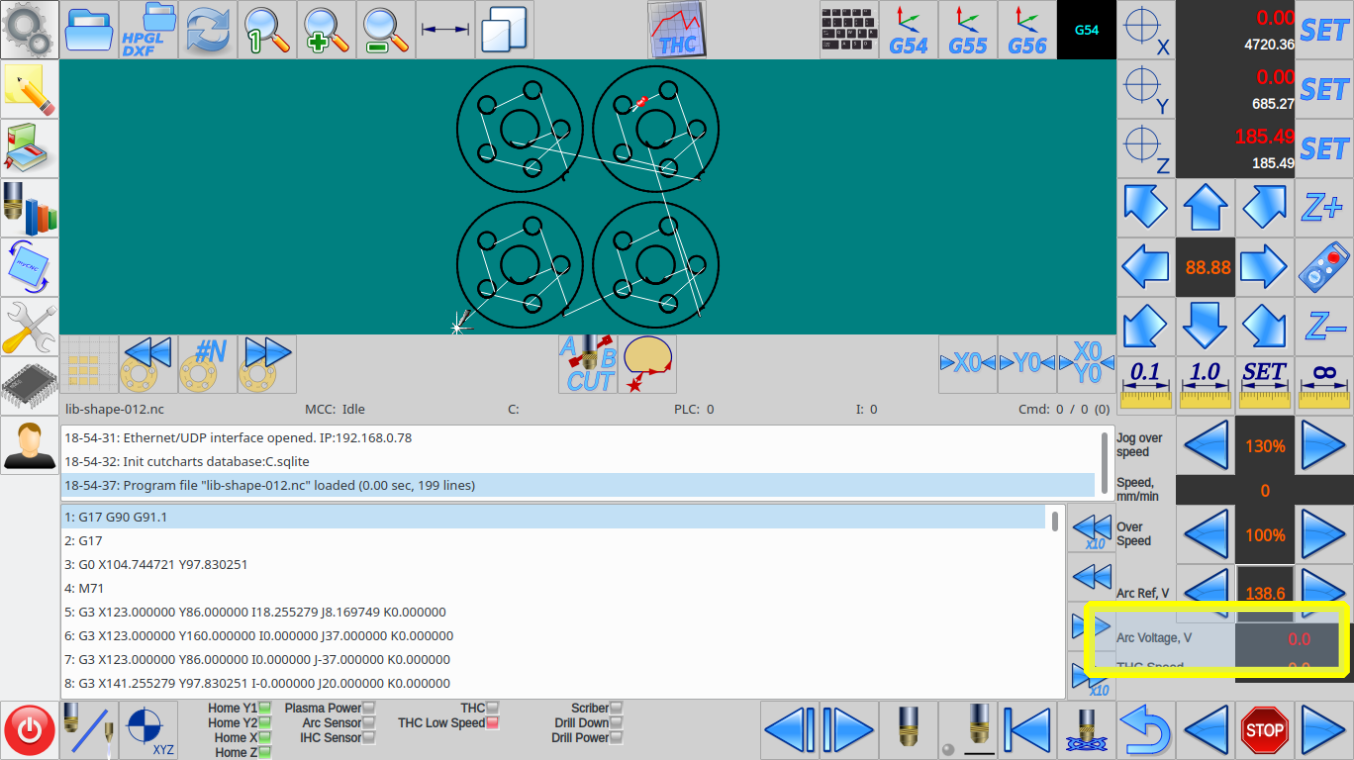

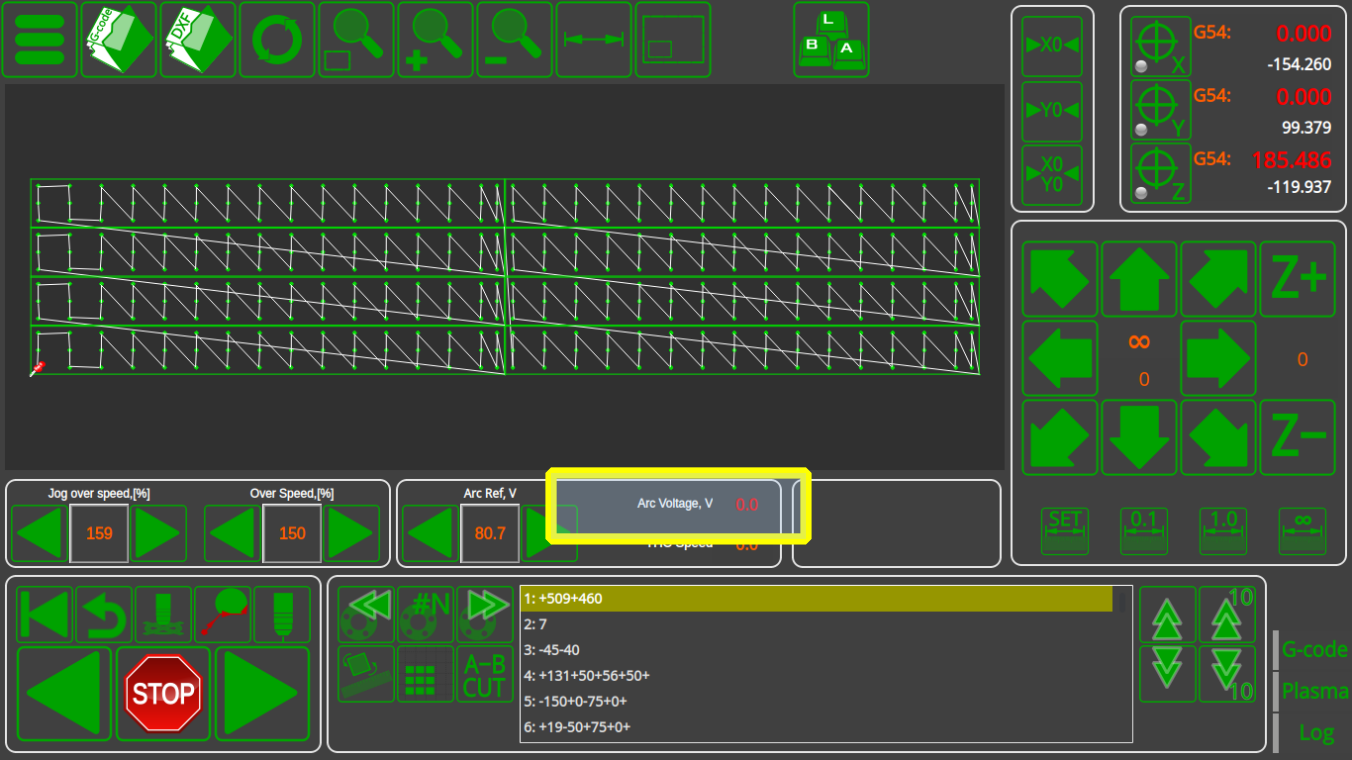

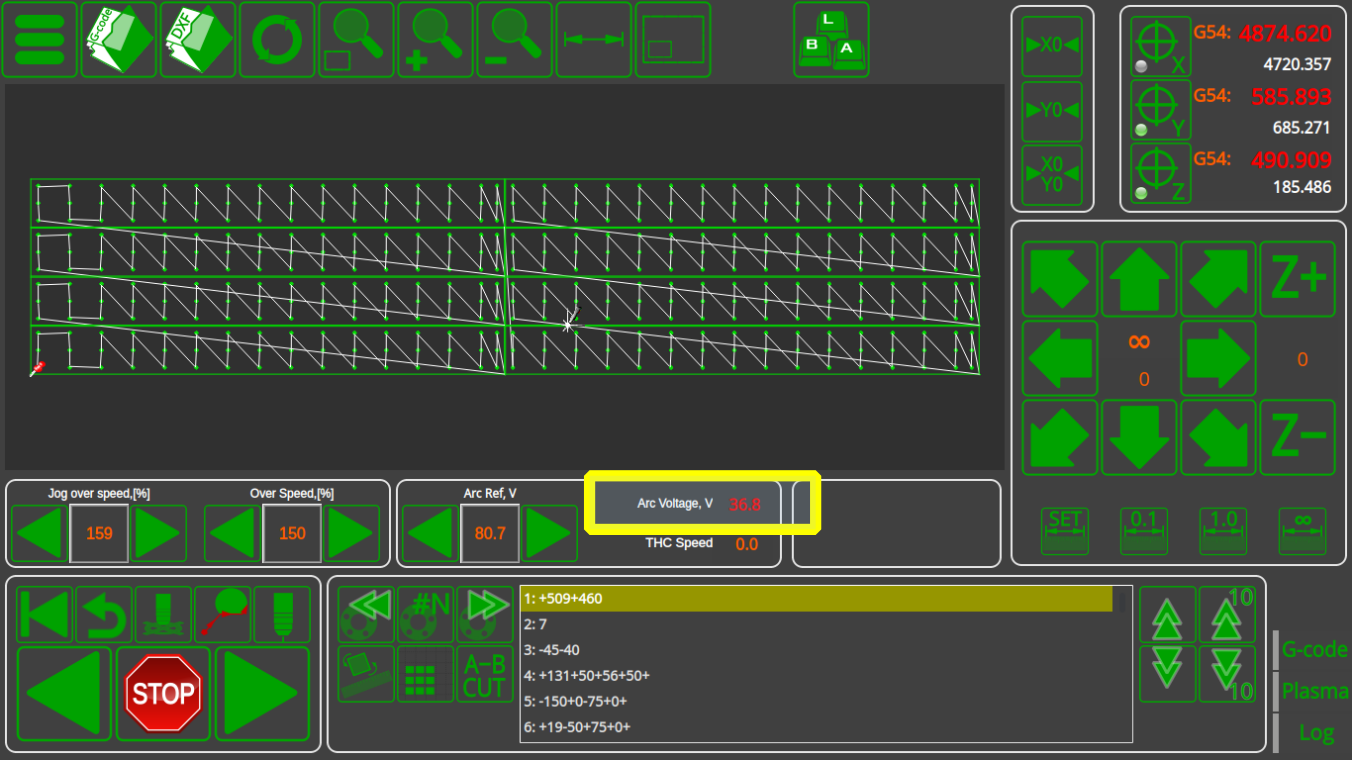

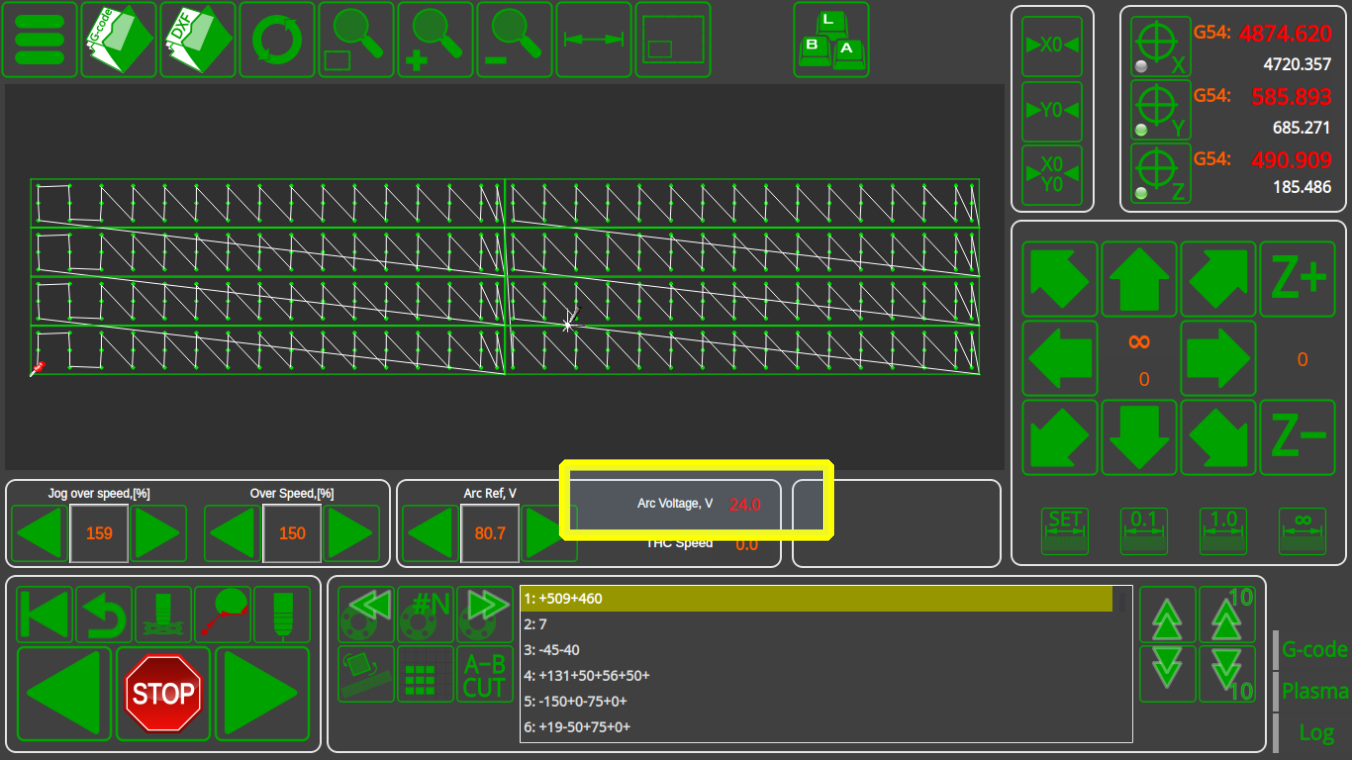

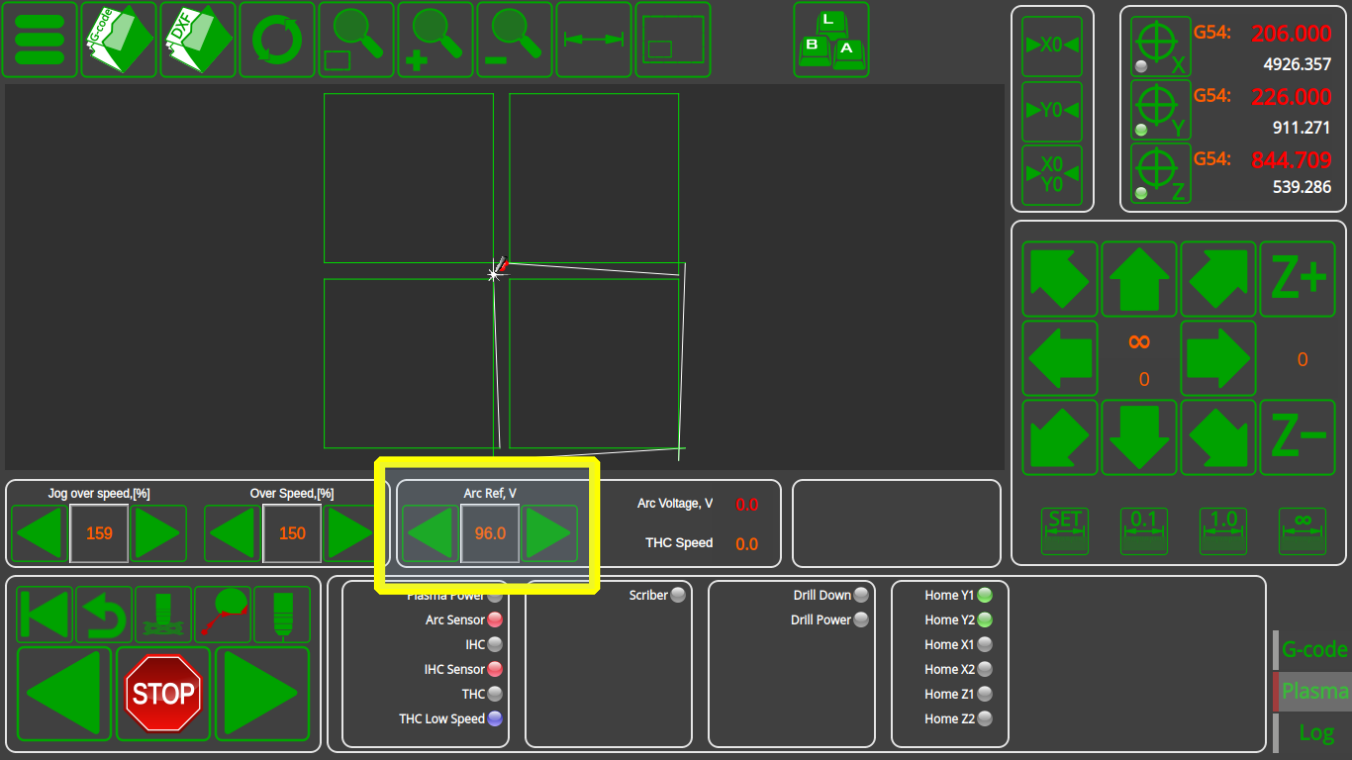

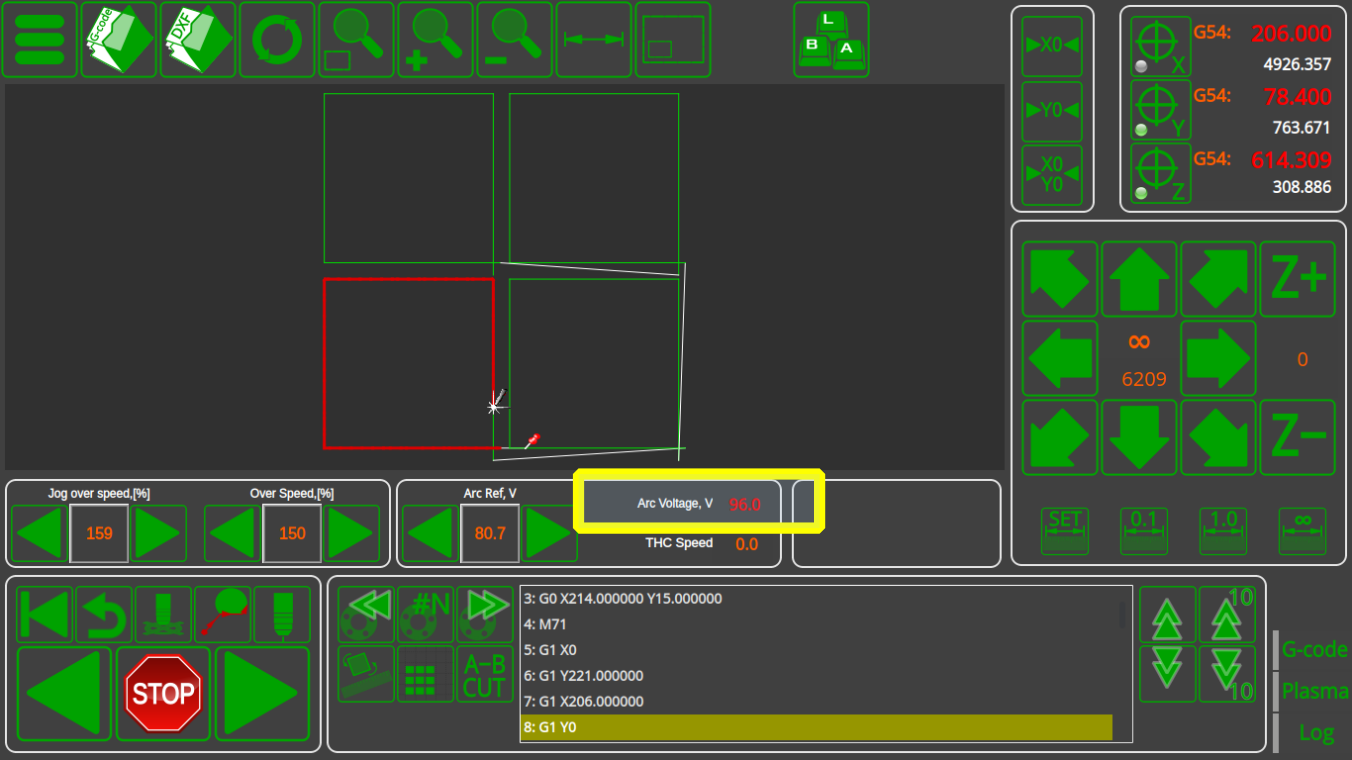

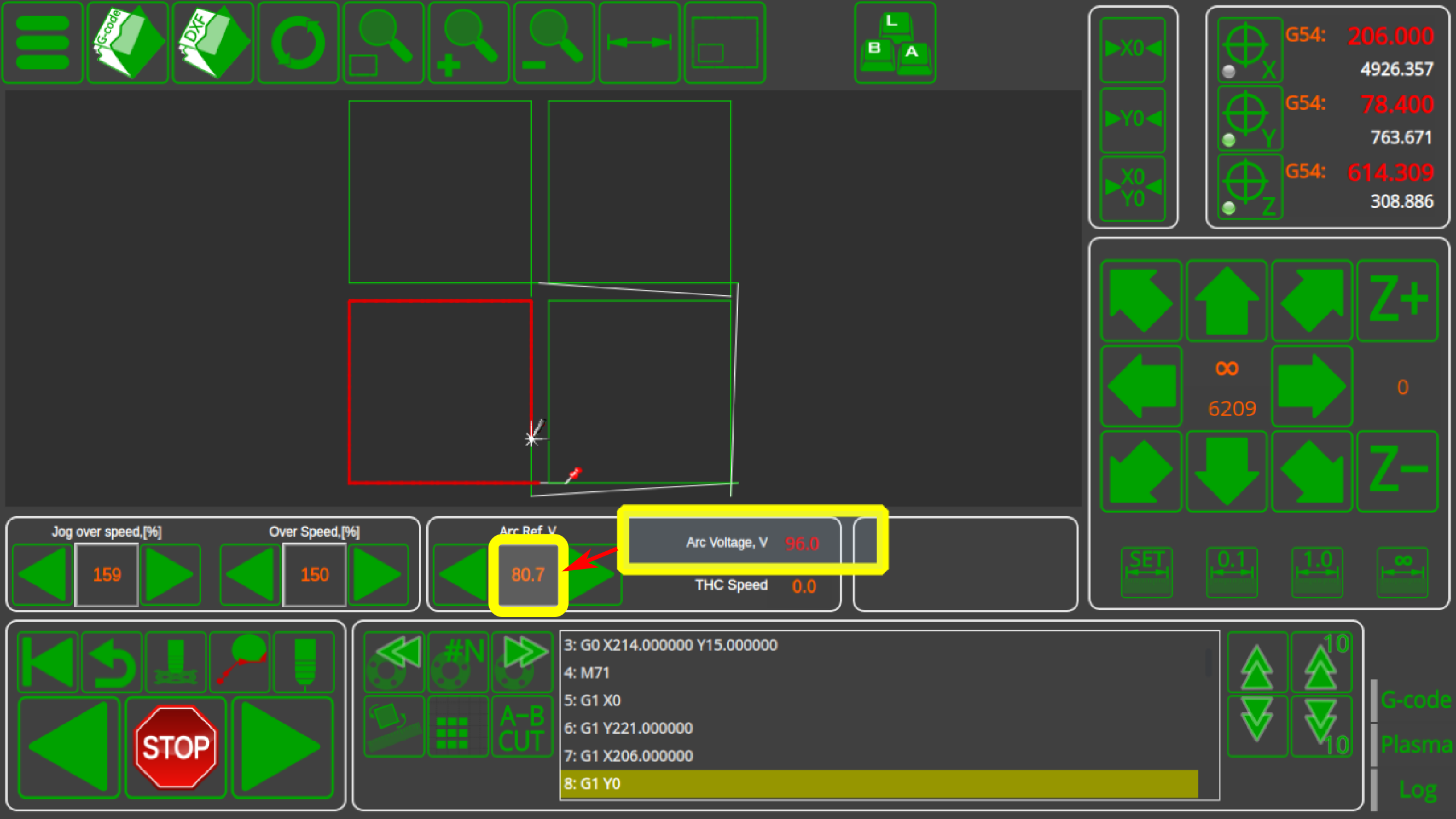

Arc Voltage measured value is displayed on the main myCNC screen. Arc voltage signal should be connected to the proper ADC input number. This number can be set up in the THC configuration dialog.

Connect the test signal (for example, 24V from test power source) to the THC ADC input and check the voltage value displayed. Test signal should be connected through the Arc Voltage Divider you use (not directly to the board's ADC input).

If you don't see any voltage on the display, then:

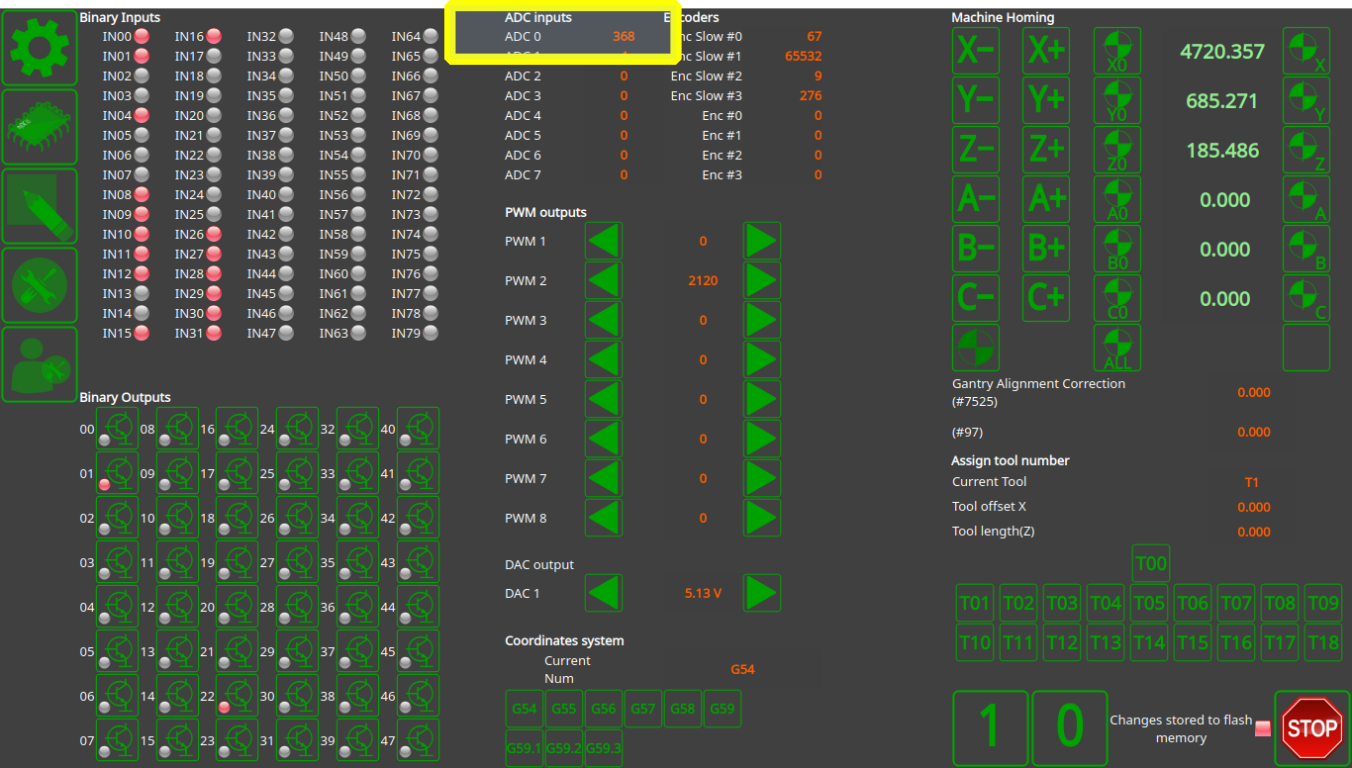

- go to the Diagnostics widget,

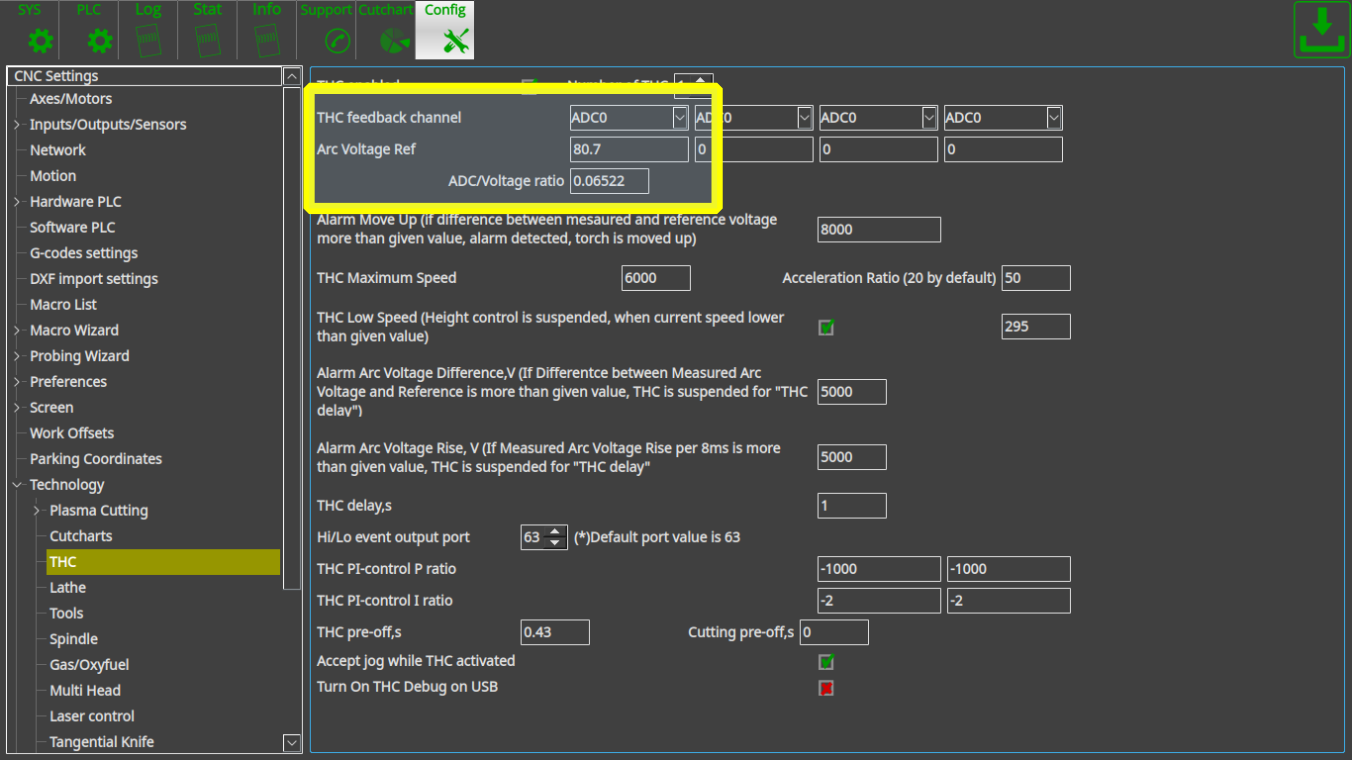

- go to the THC settings widget again and fix the “ADC/Voltage” ratio. The value should adjusted to

K1=24/36.8=0.6522

Current ratio is “0.1” (on the screen above), so total ratio would be

K=0.1*24/36.8=0.06522

Check Additional THC/PID settings

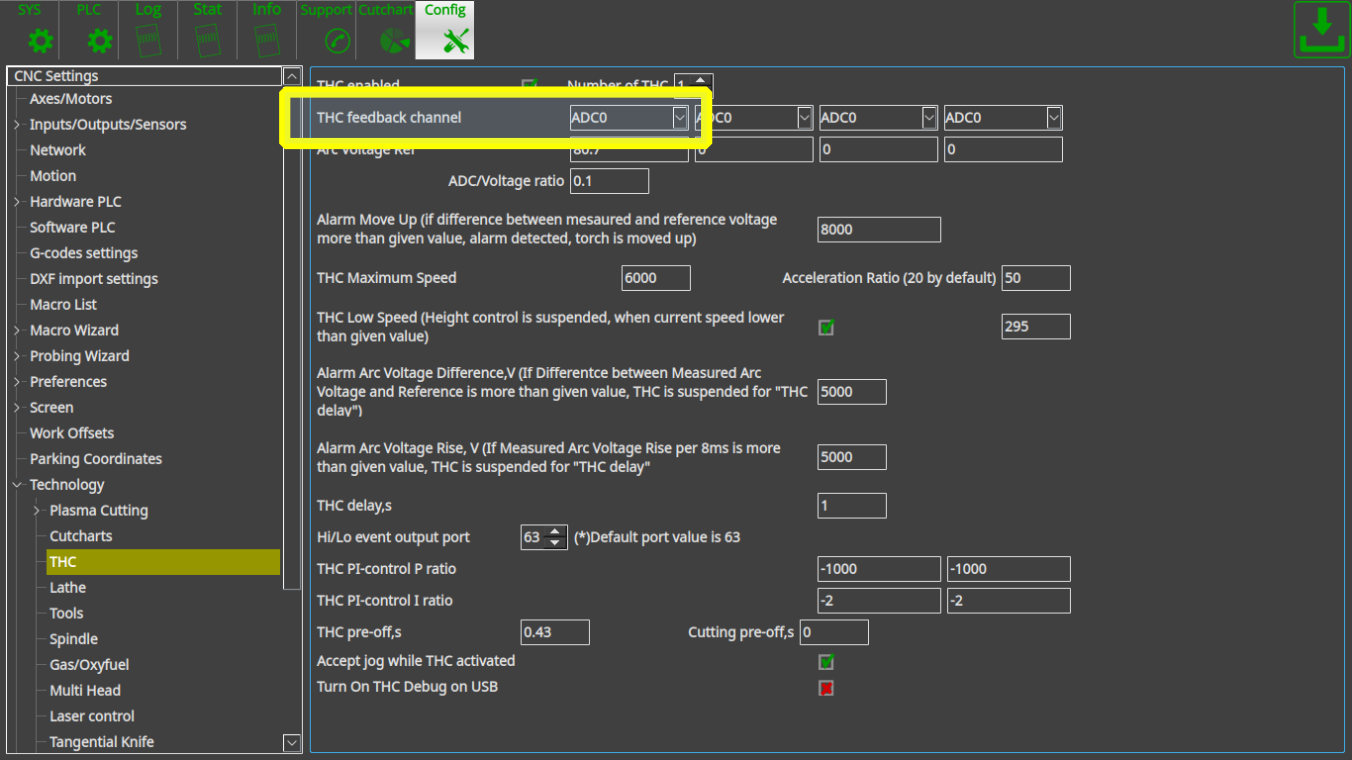

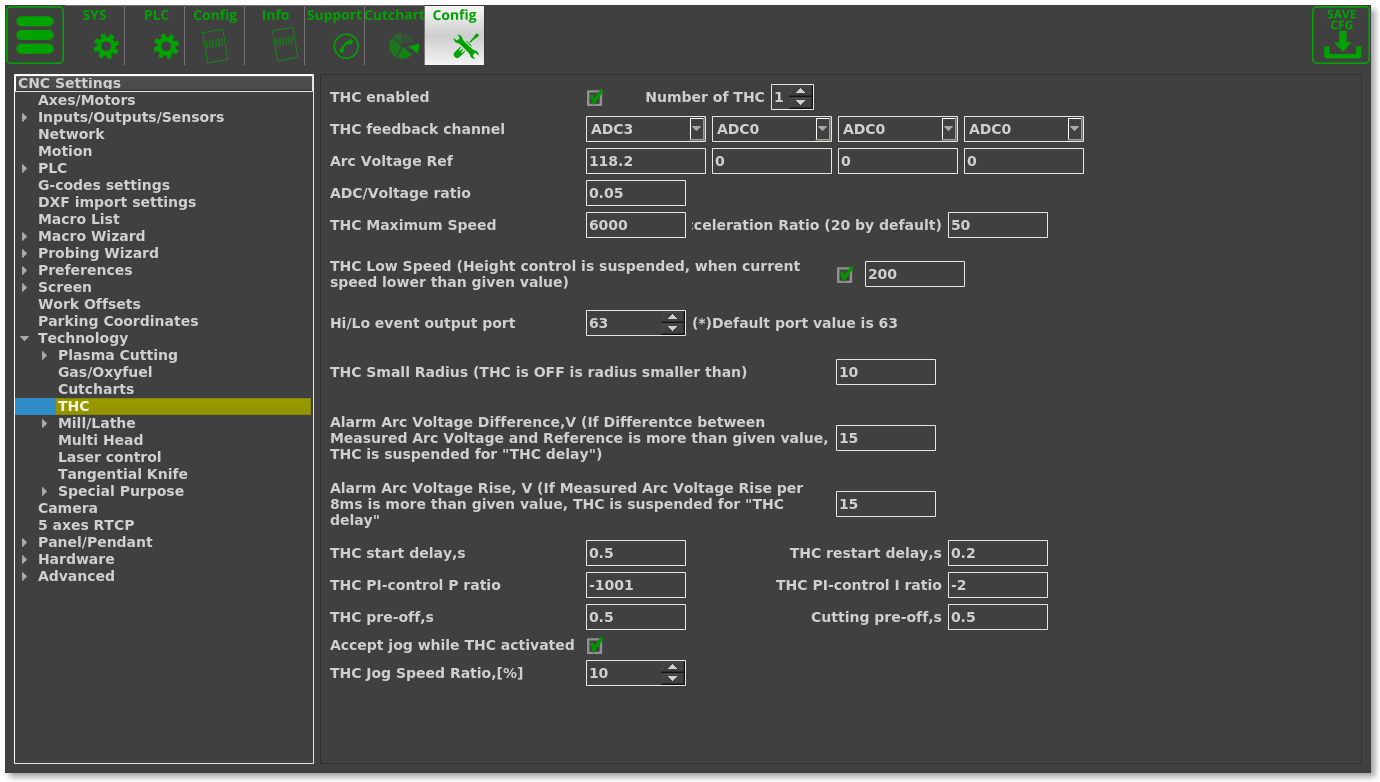

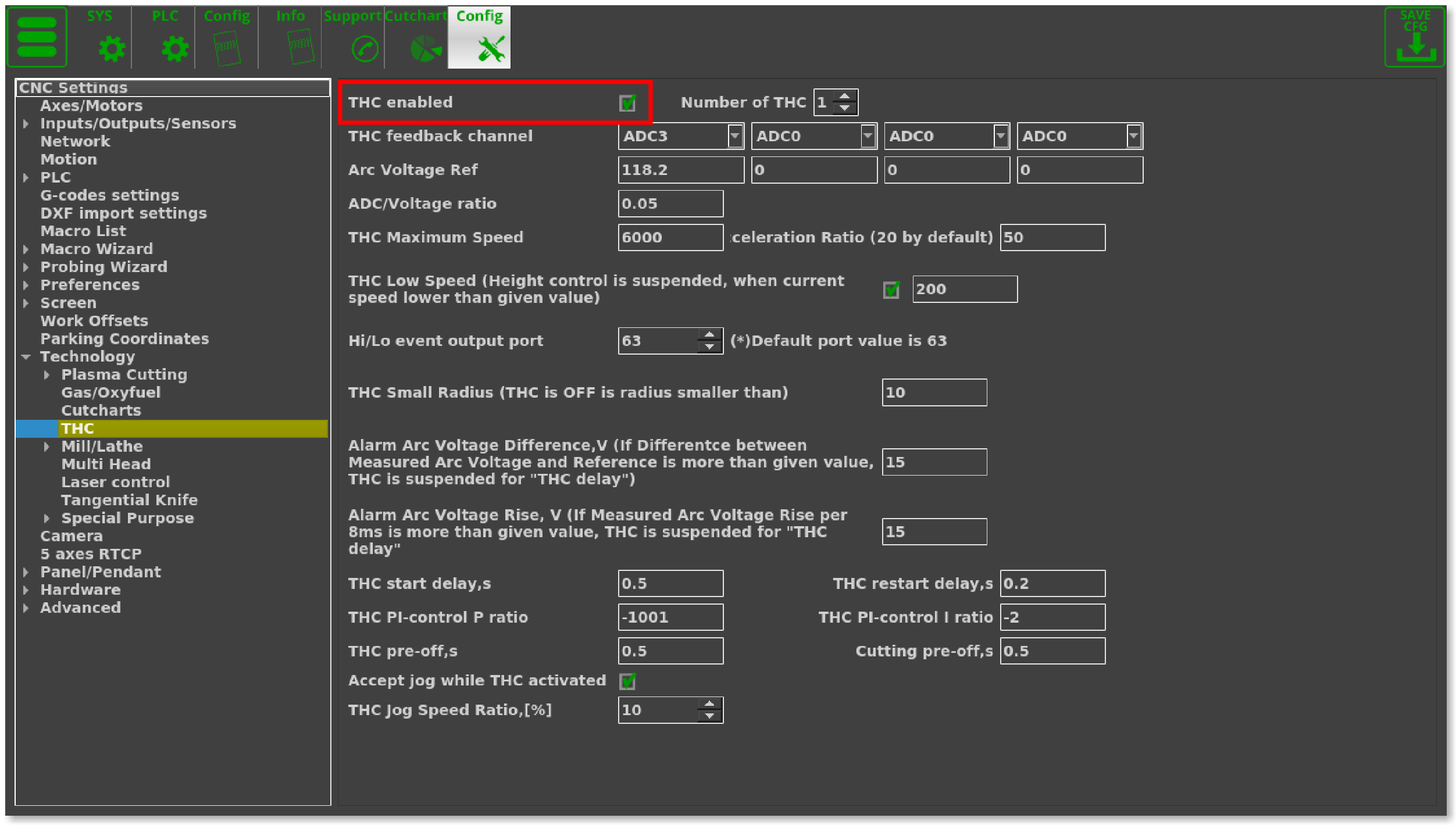

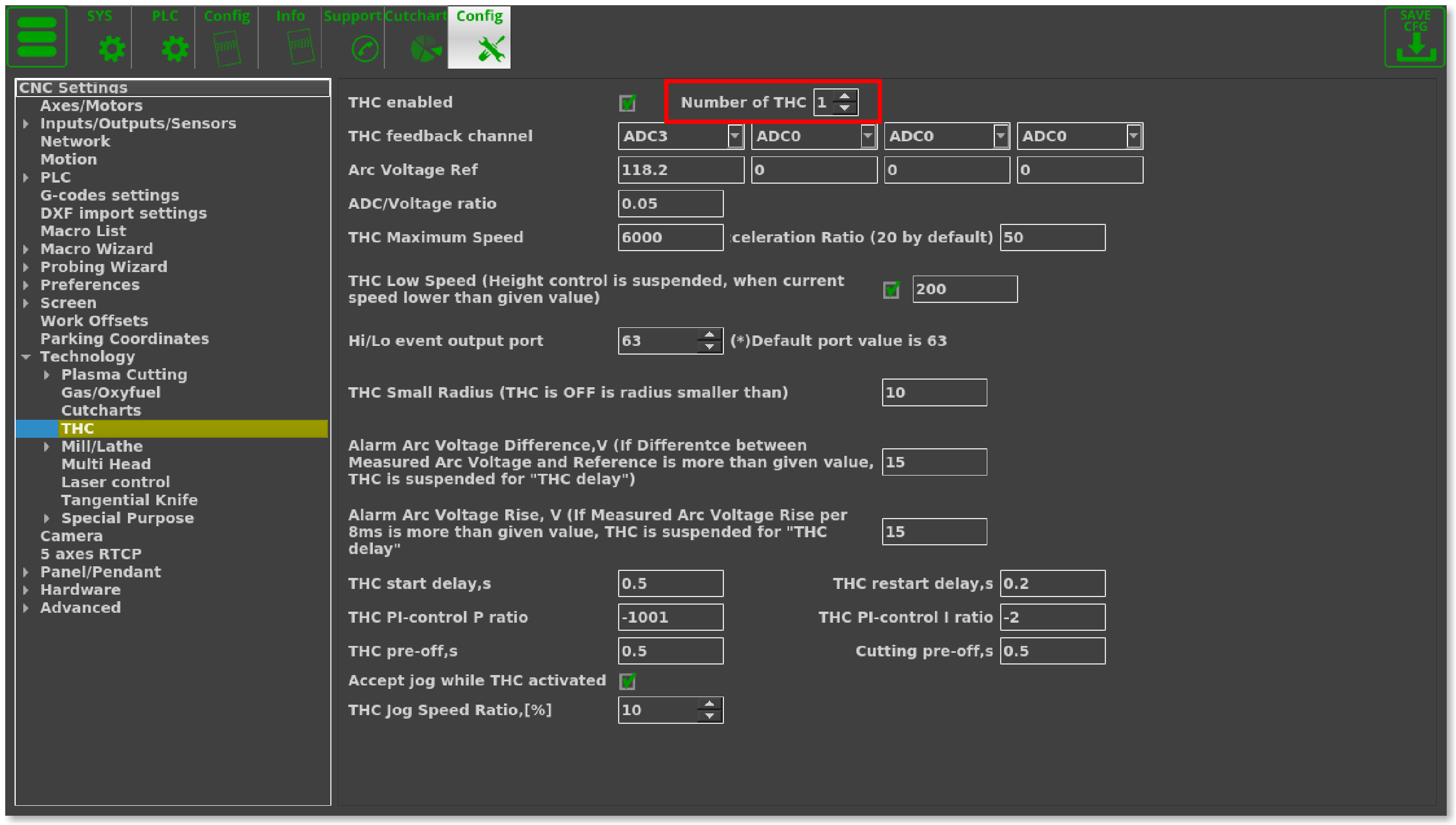

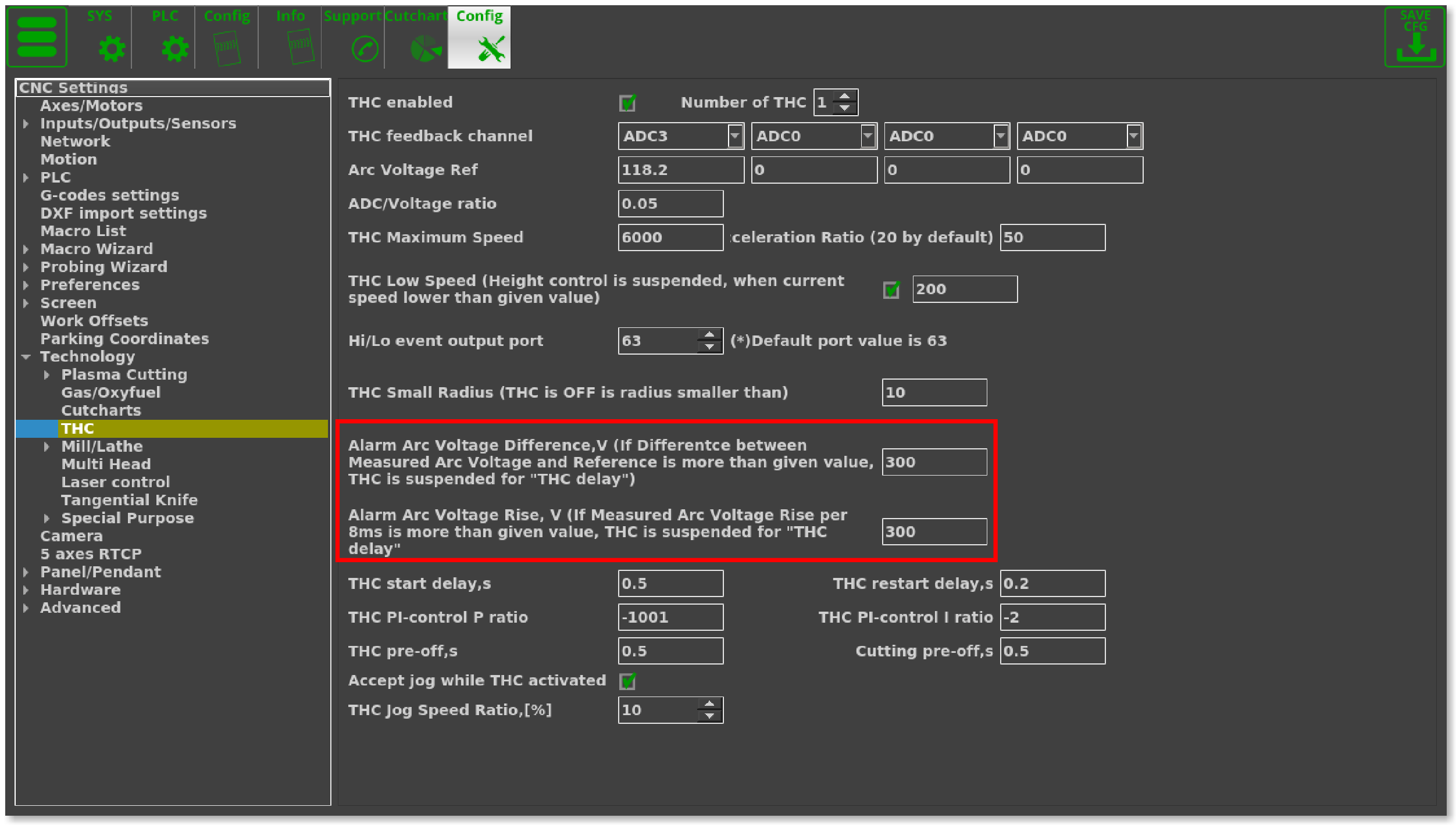

After the initial ADC checkup has been completed, more granular THC settings can be seen to. These are all located in Settings > Config > Technology > THC

Note that the screenshot above illustrates the default values only. “Recommended” values depend on machine speed, sheet thickness, plasma power source and torch type, and thus will vary from user to user.

In order to troubleshoot the THC settings, follow the instructions below:

1. Check that the green check mark is ON in the THC Enabled field.

2. Check that the correct number of THC is selected (usually 1)

3. Check that the feedback channel has been chosen correctly.

4. Select your reference voltage. This can be done in two ways:

- By using a reference value (from the Cutcharts window or from your manufacturer's manual tables)

OR

- By first disabling THC and bringing the plasma arc to a desirable position and then recording the reference voltage.

- Disable THC & IHC

- Set desired height from the sheet

- Record the Arc Voltage obtained during the cut and use that value as your reference arc voltage

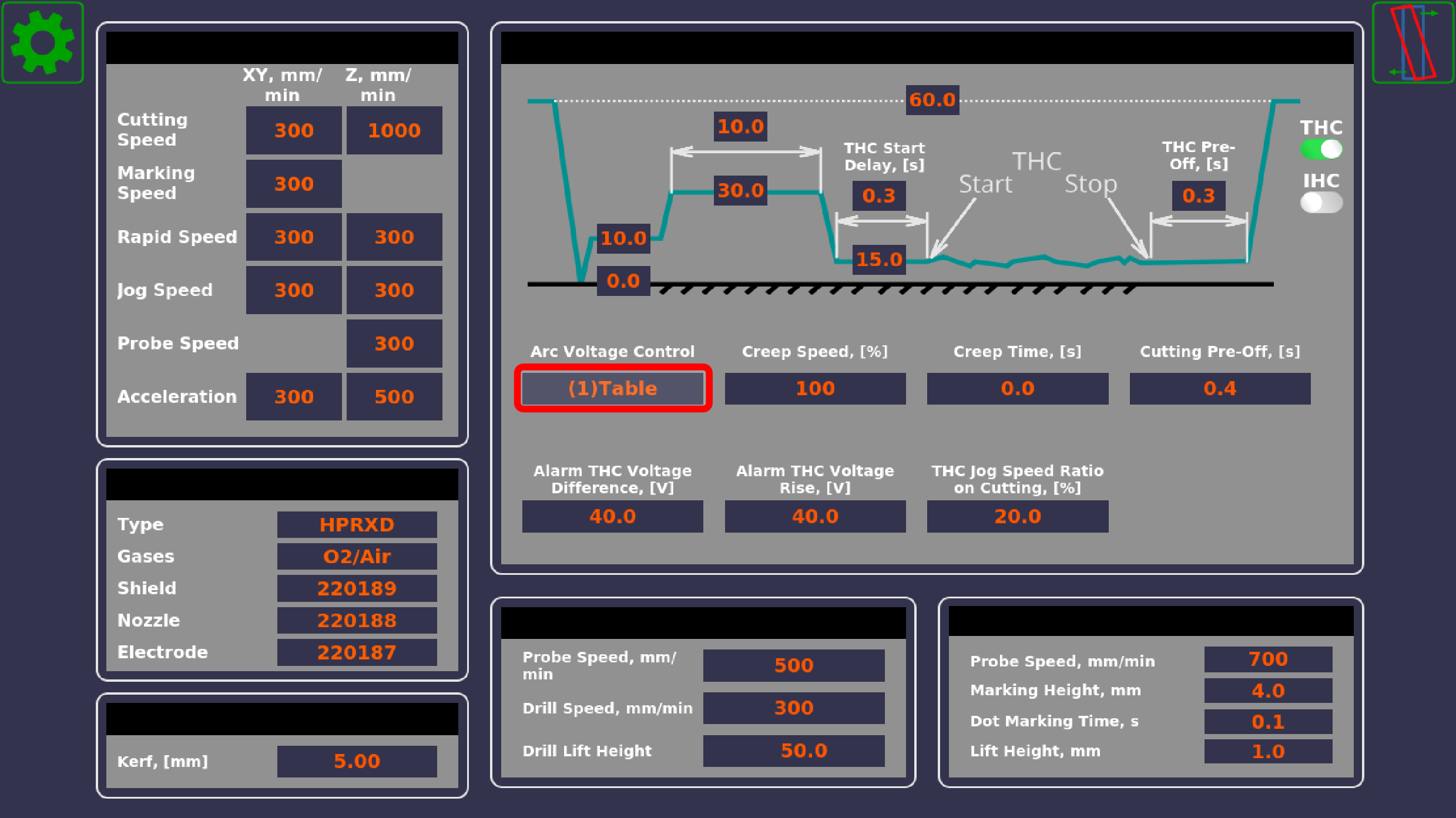

Note that for both of these methods, it is necessary to have the Arc Voltage Control set to (1)Table in the User Settings panel:

5. During the cut, the measured arc voltage should not be drastically different from the reference voltage. If it is, check the Alarm Arc Voltage Difference and Alarm Arc Voltage Rise values. These settings are useful in situations where, for example, there has been a single rapid spike to a new voltage value, such as after metal warping due to the heat. In this case, the machine will temporarily disable THC until the rise (the derivative of the voltage difference) is stable again. This is useful for when Torch Height Control needs to be turned off temporarily, but still function after a voltage spike.

However, in situations where the THC system is being set up, if the reference voltage is very different from the real measured voltage (more than these Difference and Rise values), Torch Height Control may not start at all. In this scenario, you can increase these values (for example, from 15V to 50-60V) until they allow for the THC to start.

These steps should allow the user to check the most important settings which might conflict and cause issues with the THC starting. In order to fully set up Torch Height Control, please consult the full setup manual located here.