Table of Contents

Cutcharts

myCNC software supports cutcharts. Cutting parameters such as Cutting speed, Process current, Arc voltage reference, Ignition Height, Pierce height, Pierce time, Cutting height, Kerf compensation and others can be loaded from the Cutcharts depending on the plasma power source, material type, material thickness and gases/nozzles used.

Cutchart database is stored in the myCNC software as an SQLite database file. The database can be filled manually or imported automatically from an XML or CSV file format.

Importing the cutchart database

In order to import the cutchart database:

- Go to the myCNC Downloads page, scroll down to Plasma Cutting Cutcharts and download the necessary cutchart file (note whether you are downloading an SQLite or a CSV file)

- Move the downloaded file to the folder from which the SQLite files are loaded

- Ubuntu Mate: /opt/myCNC/Cutcharts

- Tinkerboard computers: /home/USERNAME/myCNC/Cutcharts (usually /home/operator/myCNC/Cutcharts)

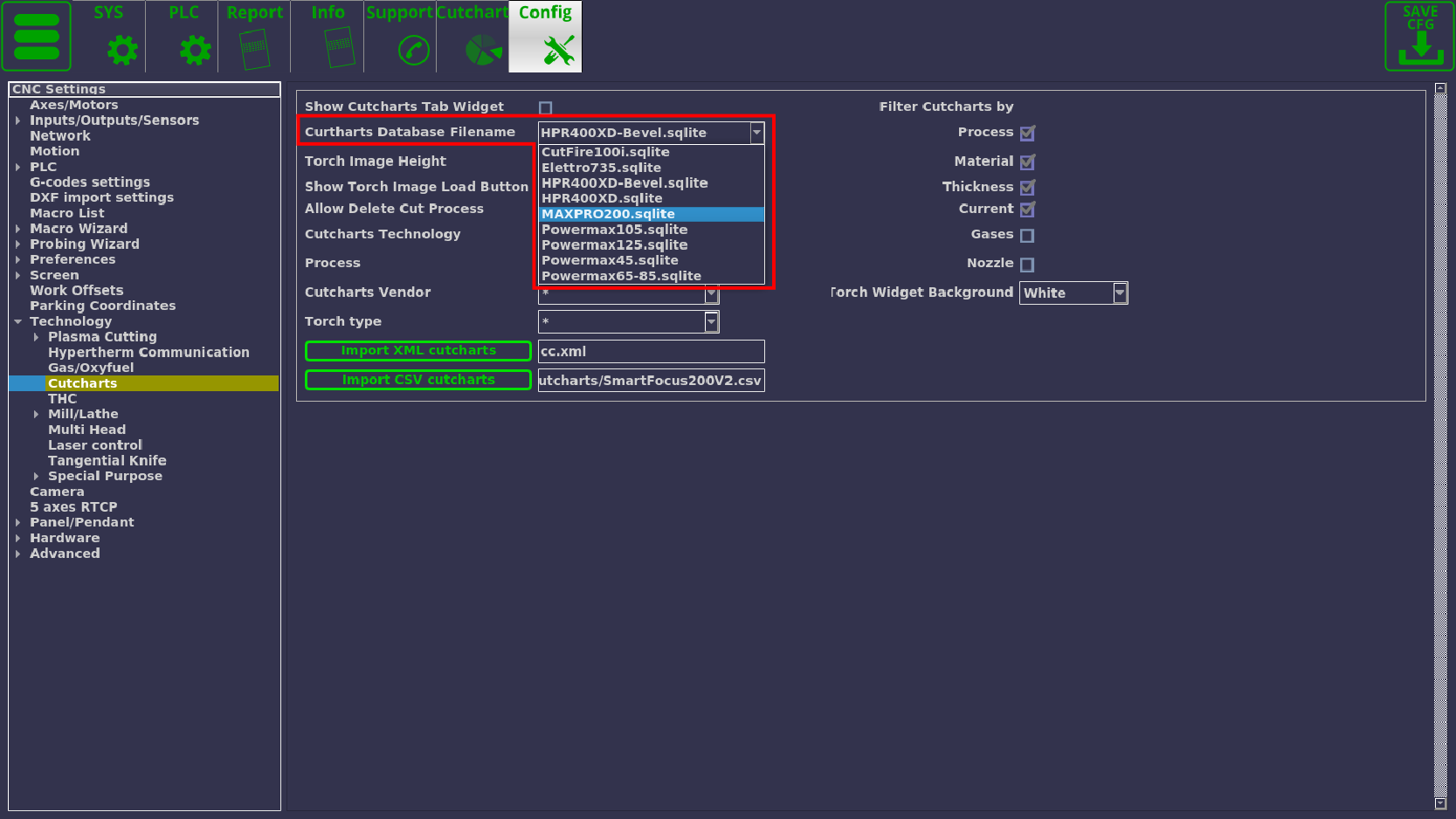

- Go to Settings > Config > Technology > Cutcharts

- In the Cutcharts Database Filename field, select the file name that you would like to load into myCNC from the dropdown (for example, MAXPRO200.sqlite).

- Save and reload the program. The file should now be loaded into the myCNC system.

CSV files

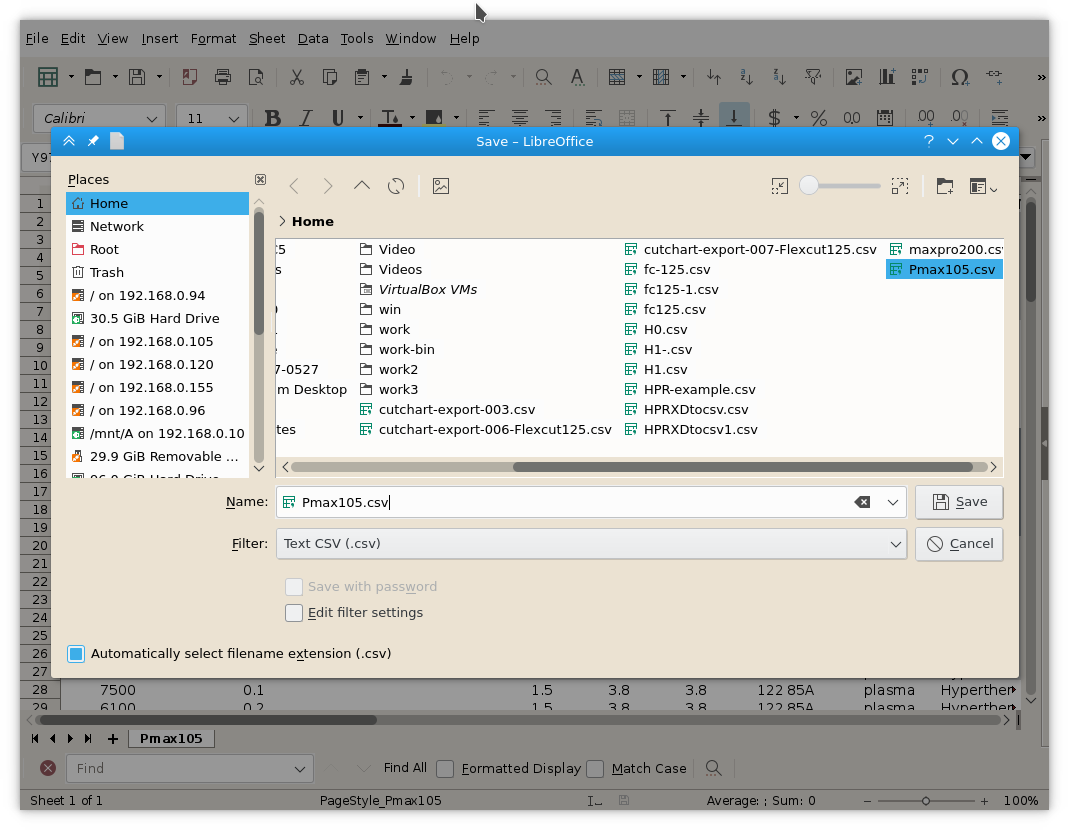

Comma Separated Values (CSV) is a widely used text format. XLS/ODT files can be easily saved as CSV files directly from Libre Office Calc or Microsoft Excel.

For example, select Save as in Libre Office menu, select Text CVS and choose the following in the CSV options:

- “;” as field delimiter

- “” (empty) as text delimiter

These delimiters allow the file to distinguish between different entries that are typed in. The file should now be ready to use.

Parameters List

Parameters List that can be stored in Cutchart is shown in the table below:

| Parameter Name | Description |

|---|---|

| Technology | Cutting technology (Plasma, Oxy-fuel, laser etc) |

| Vendor | Cutchart vendor |

| Revision | Cutchart Revision |

| TorchType | Torch Type |

| MaterialThickness | Material Thickness |

| MaterialType | Material Type (Mild Steel, Stainless Stel, Aluminium, Brass) |

| Process | Process definition (like HPR xd, Fine-Cut etc) |

| SpecificMaterial | Specific materail (like Bevel cutting) |

| CollisionDelayTime | — |

| HoldPierceHeightTime | — |

| NoMoveAtHolecut | — |

| Gas_Select1_Type | HPR Automatic gas console Gas Mix Select #1 |

| Gas_Select2_Type | HPR Automatic gas console Gas Mix Select #2 |

| Consumable part numbers | |

| ShieldRetainingCap | Shield Retaining Cap part number |

| Shield | Shield part number |

| NozzleRetainingCap | Nozzle Retaining Cap part number |

| Nozzle | Nozzle part number |

| SwirlRing | Swirl Ring part number |

| Electrode | Electrode part number |

| WaterTube | Water Tube part number |

| Oxy-fuel cutting parameters | |

| TimeIgnitionValve | Oxyfuel cutting: Ignition time |

| TimeIgnitionSparkle | Oxyfuel cutting: Sparkle time |

| TimePreheat | Oxyfuel cutting: Preheat time |

| TimeSoftOxyStart | Oxyfuel cutting: Cutting Oxygen Soft start time |

| AGC_Ignition_Fuel | Oxyfuel cutting: Automatic Gas Console - Fuel on Ignition |

| AGC_Ignition_OxyHeat | Oxyfuel cutting: Automatic Gas Console - Preheat Oxygen on Ignition |

| AGC_Preheat_Fuel | Oxyfuel cutting: Automatic Gas Console - Fuel on Preheat |

| AGC_Pierce_Fuel | Oxyfuel cutting: Automatic Gas Console - Fuel on Pierce |

| AGC_Pierce_OxyHeat | Oxyfuel cutting: Automatic Gas Console - Cutting Oxygen on Ignition |

| AGC_Pierce_OxyCut | Oxyfuel cutting: Automatic Gas Console - Fuel on Ignition |

| AGC_Cutting_Fuel | Oxyfuel cutting: Automatic Gas Console - Fuel on Cutting |

| AGC_Cutting_OxyHeat | Oxyfuel cutting: Automatic Gas Console - Preheat Oxygen on Cutting |

| AGC_Cutting_OxyCut | Oxyfuel cutting: Automatic Gas Console - Cutting Oxygen on Cutting |

| AGC_Pilot_Fuel | Oxyfuel cutting: Automatic Gas Console - Fuel on Pilot flame |

| AGC_Pilot_OxyHeat | Oxyfuel cutting: Automatic Gas Console - Oxygen Fuel on Ignition |

| Cutting Parameters | |

| CutSpeed | Cut Speed |

| Kerf | Kerf Compensation |

| CreepTime | |

| CreepSpeed | Creep Speed (see above) |

| Torch Height Control Parameters | |

| HC_IgnitionHeight | Ignition Height (Transfer Height) |

| HC_PierceHeight | Pierce Height |

| HC_CutHeight | Cut Height |

| HC_PierceHeightFactor | Hypertherm Parameter, different way to program similar to Pierce Height |

| HC_PierceDelay | Pierce Delay (Pierce Time) |

| HC_ArcVoltage | Height control reference voltage (defines cutting height) |

| HC_ControlDelay | Height control delay - Height control activated after pierce + this delay finished |

| Plasma Cutting | |

| ProcessCurrent | Plasma: Process current |

| SetArcCurrent | Set Arc Current parameter to be sent to PLasma SOurce (id supported) |

| CornerReduction | Reduction Process current on corners to reduce overheat and improve corner cut quality |

| PlasmaShieldGases | Plasma cutting gases for Plasma and Shield channels |

| Plasma_Gas | Gas type for Plasma channel |

| Shield_Gas | Gas type for Shield channel |

| MixGas1 | HPR Gas console MixGas1 Parameter |

| MixGas2 | HPR Gas console MixGas2 Parameter |

| Plasma Automatic Gas Console | |

| AGC_PlasmaPreflow | Plasma: Automatic Gas Console Plasma channel Preflow gas pressure |

| AGC_ShieldPreflow | Plasma: Automatic Gas Console Shield channel Preflow gas pressure |

| AGC_PlasmaCutflow | Plasma: Automatic Gas Console Plasma channel Cutflow gas pressure |

| AGC_ShieldCutflow | Plasma: Automatic Gas Console Shield channel Cutflow gas pressure |

| Plasma Manual Gas Console | |

| MGC_PlasmaPreflow | Plasma: Manual Gas Console Plasma channel Preflow gas pressure |

| MGC_ShieldPreflow | Plasma: Manual Gas Console Shield channel Preflow gas pressure |

| MGC_PlasmaCutflow | Plasma: Manual Gas Console Plasma channel Cutflow gas pressure |

| MGC_ShieldCutflow | Plasma: Manual Gas Console Shield channel Cutflow gas pressure |

| Additional Parameters | |

| PS_MarkingDataset | — |

| PS_TimeSpeedCountourEnd | — |

| PS_OverrideTimeway | — |

| PS_WayPlasmaOff | — |

| PS_WaySpeedCountourEnd | — |

| PS_PierceReductionDistance | — |

| PS_PierceReduction | — |

| PS_CornerCurrentReduction | — |

Adding custom images and data

In this section, we will cover an example of adding a custom nozzle image for an existing cutcharts file. A similar operation can be performed for a cutcharts file for a new plasma power source.

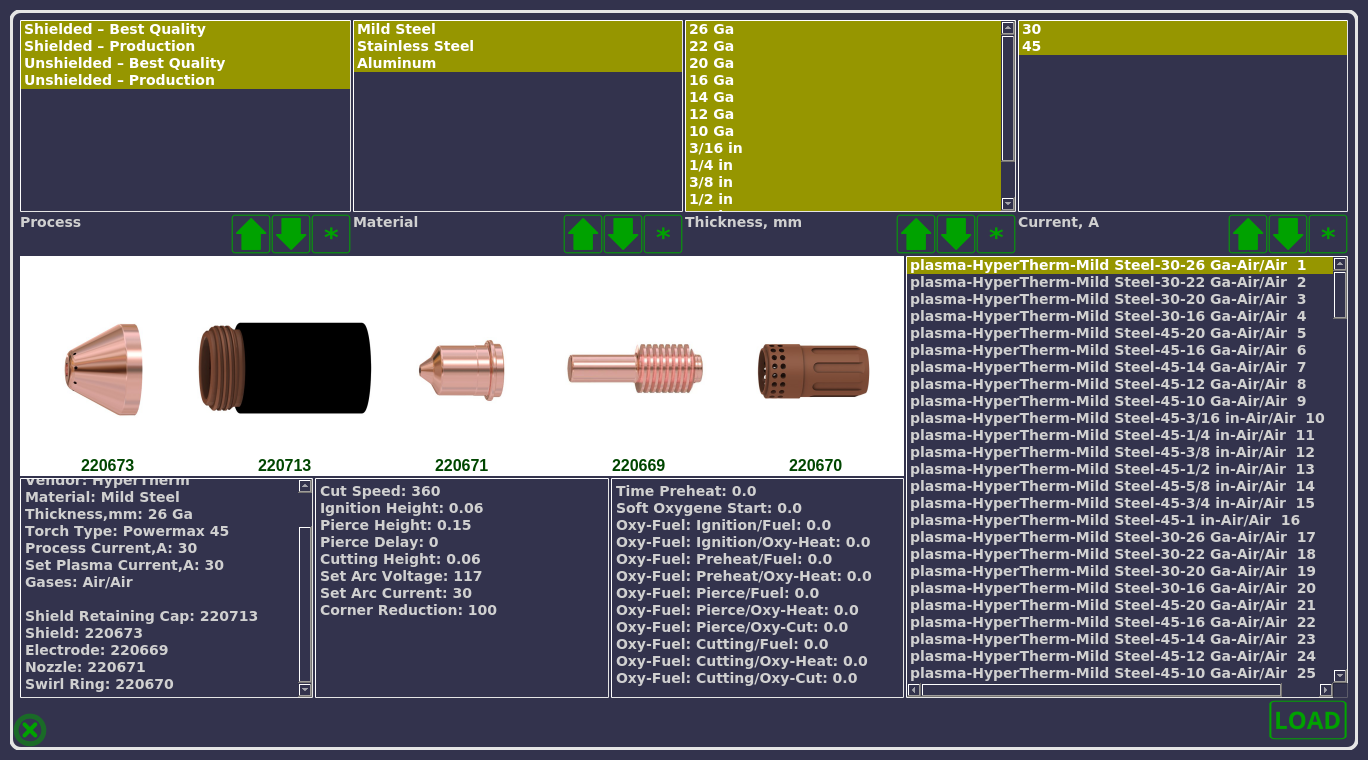

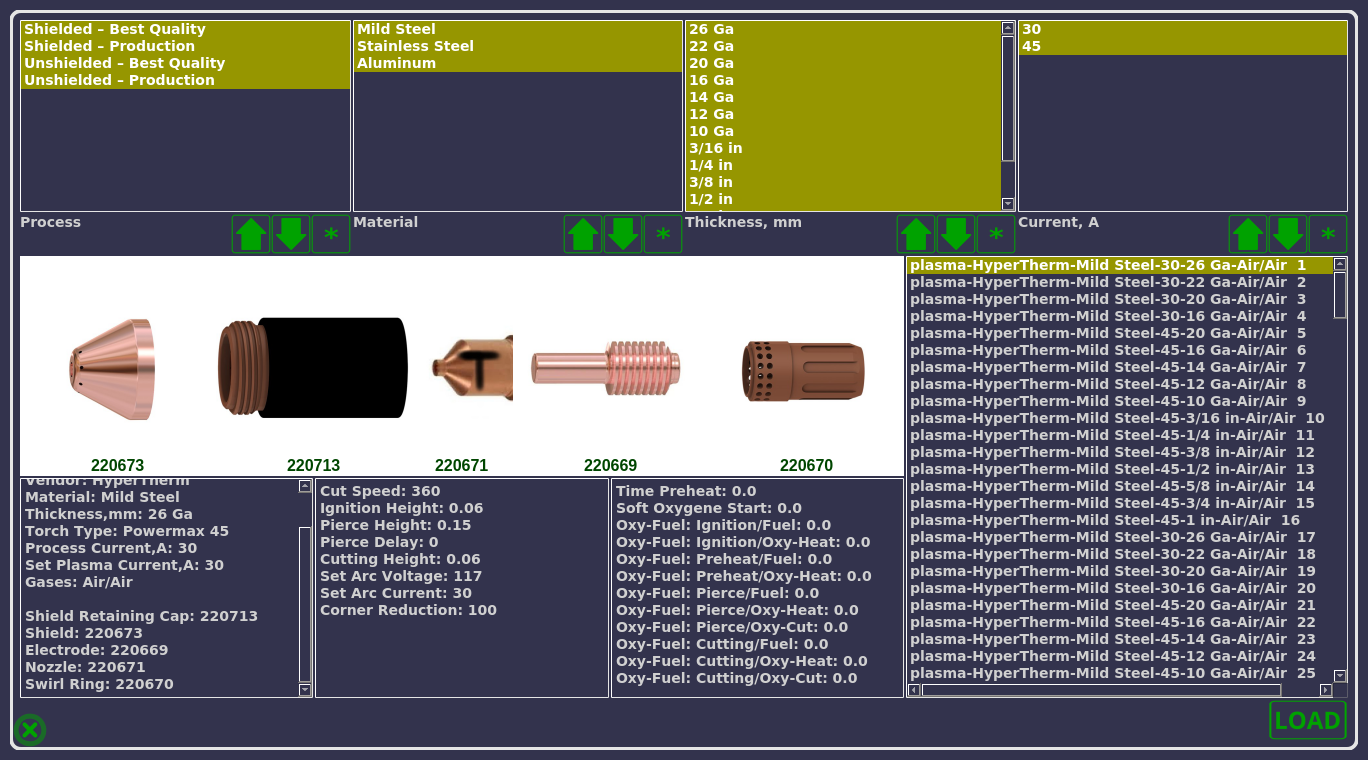

In our example, we will be using the Hypertherm Powermax45 cutcharts, which are available on our website. Below is the default cutcharts' screen:

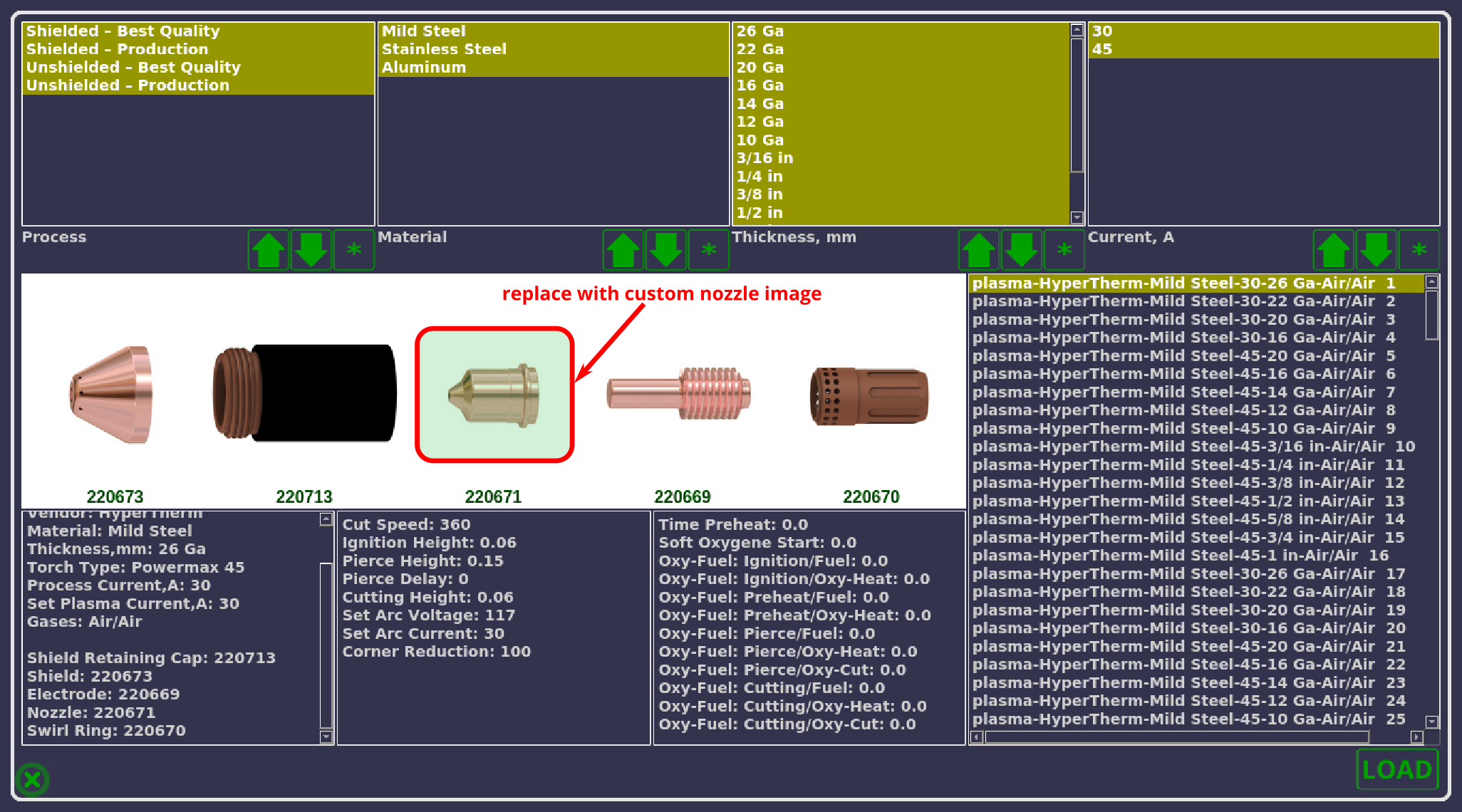

Here, we will be editing the default nozzle, pictured below:

and replacing it with the following image (titled hypertherm-test-01.jpg, with a “t” for “test”):

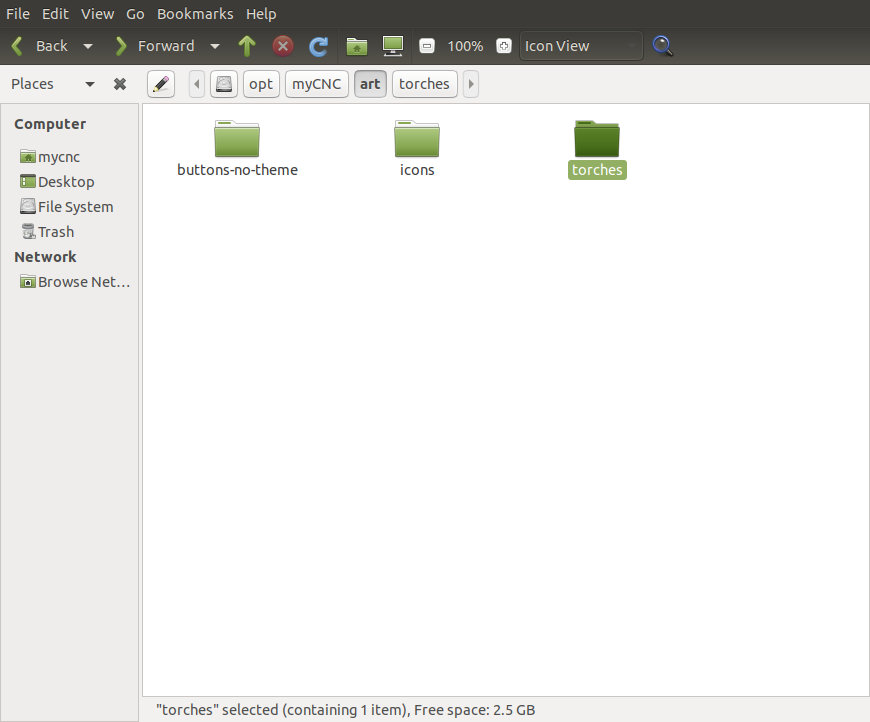

In order to do so, navigate over to your File System tab, and then into opt/myCNC/art. Within this folder, create a torches folder (if none exists):

Within the torches folder, add the custom image that will be used for your cutcharts. In case of this example, it will be hypertherm-test-01.jpg:

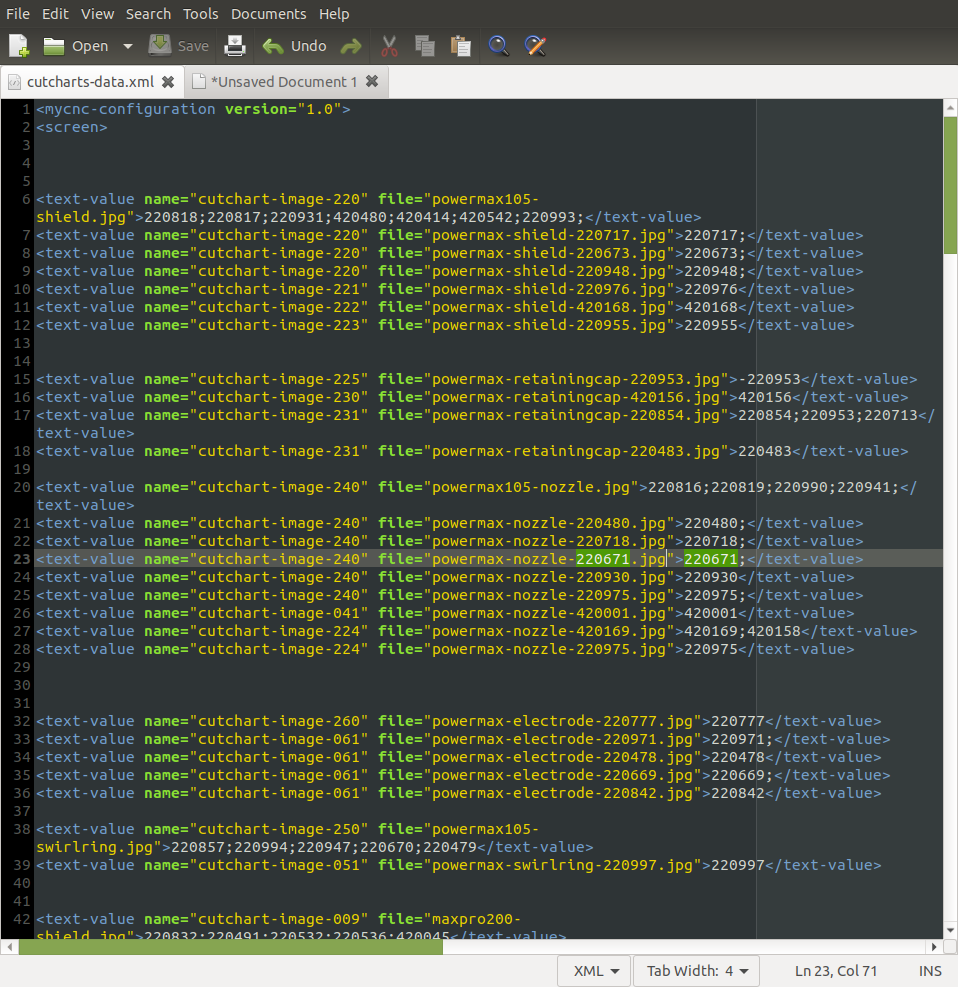

Next, navigate over to your profile folder (located in /home/.config/myCNC/profiles - X1366P in this example), locate and open the cutcharts-data.xml file. Within this file, locate the part number that you will be replacing/adding. For this example, nozzle #220671 will be edited:

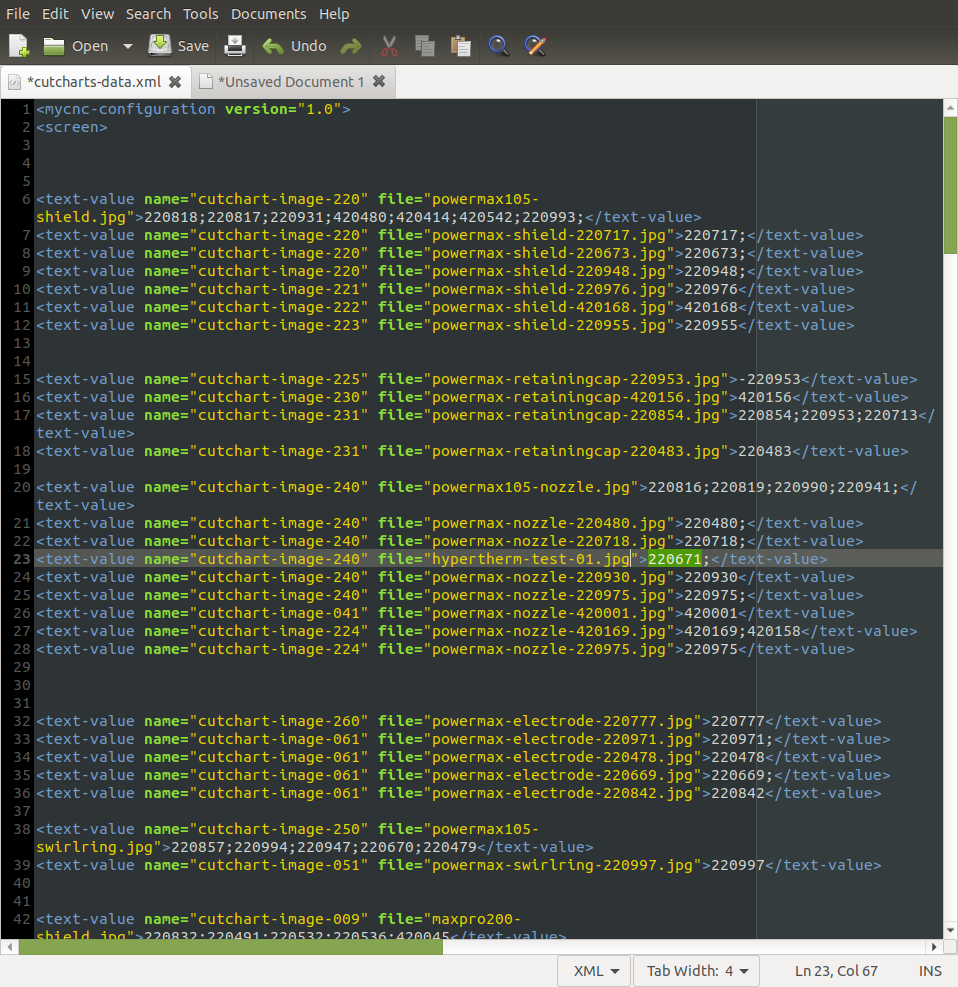

Replace the file name and save the cutcharts-data.xml file:

Upon reloading the application, the changes should take effect: