Table of Contents

Dental Mill

The myCNC software features a number of options that make it convenient in dental mill setup usage.

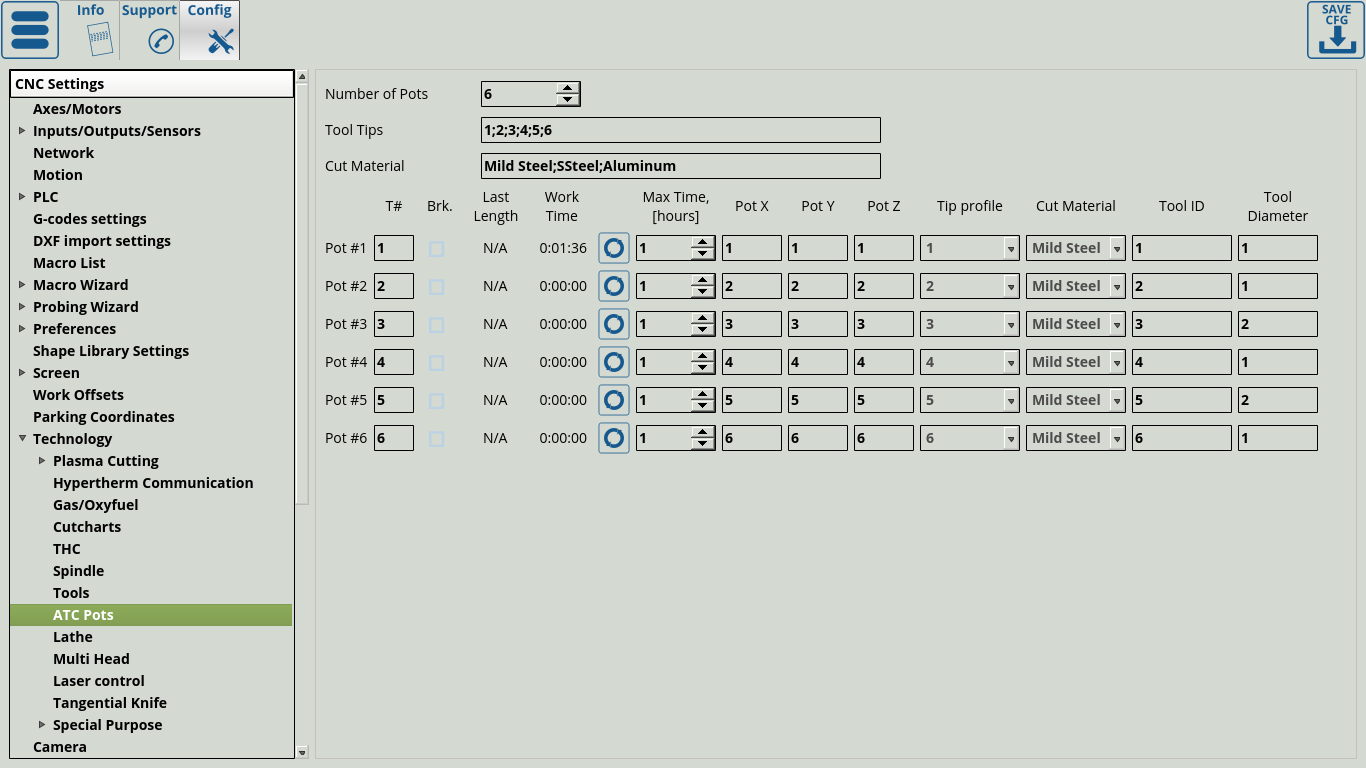

A prime example is the usage of ATC Pots (NOTE: This is an experimental feature that is currently in beta). These allow for the user to set up machines with long automated runs, with features such as Work Time/Max Work Time, different pots assigned to specific tip profiles and working materials, etc. This functionality is also described in the following manual: MyCNC Configuration Dialogs - ATC Pots.

An example of a simple on-screen visualization for the tool time could then look something like this:

<gitem where="xp" name="testpotswg" position="80;80" width="500" height="300" bgColor="##b-main" type="myitems"></gitem> <gitem where="testpotswg" name="1toolview1" type="tool1view" position="5;5" width="400" height="35" bgColor="##b-main" border-color="white" border-width="2" border-radius="3" pot="1" tnumber="5;5;25;25;19" ttime="140;5;200;25;10" tselection="#ea9a00;#936B1E" />

This sample UI element would then look the following way:

A more complex UI tool1view element may look the following way:

<gitem where="toolsview" name="1toolview13" type="tool1view" position="450;170" width="68" height="44" border-color="#3d3c3c" border-width="1" border-radius="0" pot="13" fontFamily="Roboto" fontStyle="bold" tnumber="6;5;25;16;19" tmaterial="35;8;30;12;10" ttip="12;30;20;10;10" tdiameter="40;30;20;10;10" tprogress="1;22;66;8" tselection="#ea9a00;#936B1E" />

In the example above, the following atributes are used:

- tnumber for Tool #

- tmaterial for Tool Material (from ATC Pots)

- ttip for the Tip Profile

- tdiameter for the tool's diameter

- tprogress for a visual indication of the tool usage progress (using the Tool Working Time and Max Working Time)

To find out more about screen editing, please consult the following manual: Screen Editing and Configuration

Relevant global variables

The following global variables are useful for a dental mill (due to their functionality being tied to the ATC pots):

| Global variable name | Number | Comment |

|---|---|---|

| GVAR_TOOLPOT_01_TIME | 6120 | Current work time, in s, for tool pot 1 |

| GVAR_TOOLHOLDER_01_POSITION | 6121 | +6. Tool pot 01 X position |

| 6122 | +6. Tool holder 01 Y position | |

| 6123 | +6. Tool holder 01 Z position |

This is repeated every 10 digits - for instance, the X position for each subsquent pot is defined as:

| Global variable name | Number | Comment |

|---|---|---|

| GVAR_TOOLHOLDER_02_POSITION | 6131 | +6 |

| GVAR_TOOLHOLDER_03_POSITION | 6141 | +6 |

| GVAR_TOOLHOLDER_04_POSITION | 6151 | +6 |

| GVAR_TOOLHOLDER_05_POSITION | 6161 | +6 |

Similarly, the work time for tool pot 39, for example, is defined by

| GVAR_TOOLPOT_39_TIME | 6500 |

Currently, 40 pots are reserved, with ten global variables for each pot.