Table of Contents

Oxy-fuel Cutting Setup (Gas Cutting)

This article introduces the reader to the basics of oxy-fuel (gas) cutting setup using myCNC software.

The profile screen description for the oxy-fuel cutting profiles (X1366G/X1366GA) is available here: Basic profile for Gas Cutting.

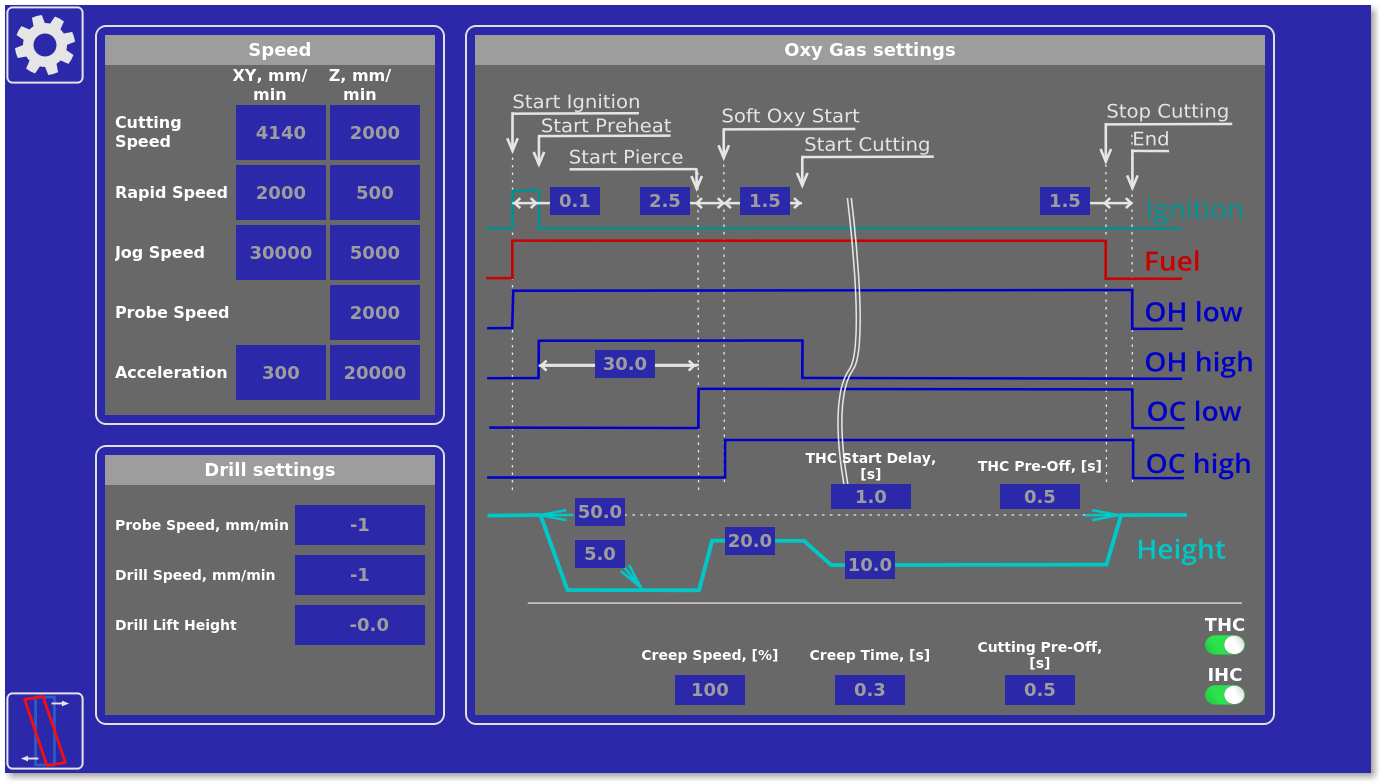

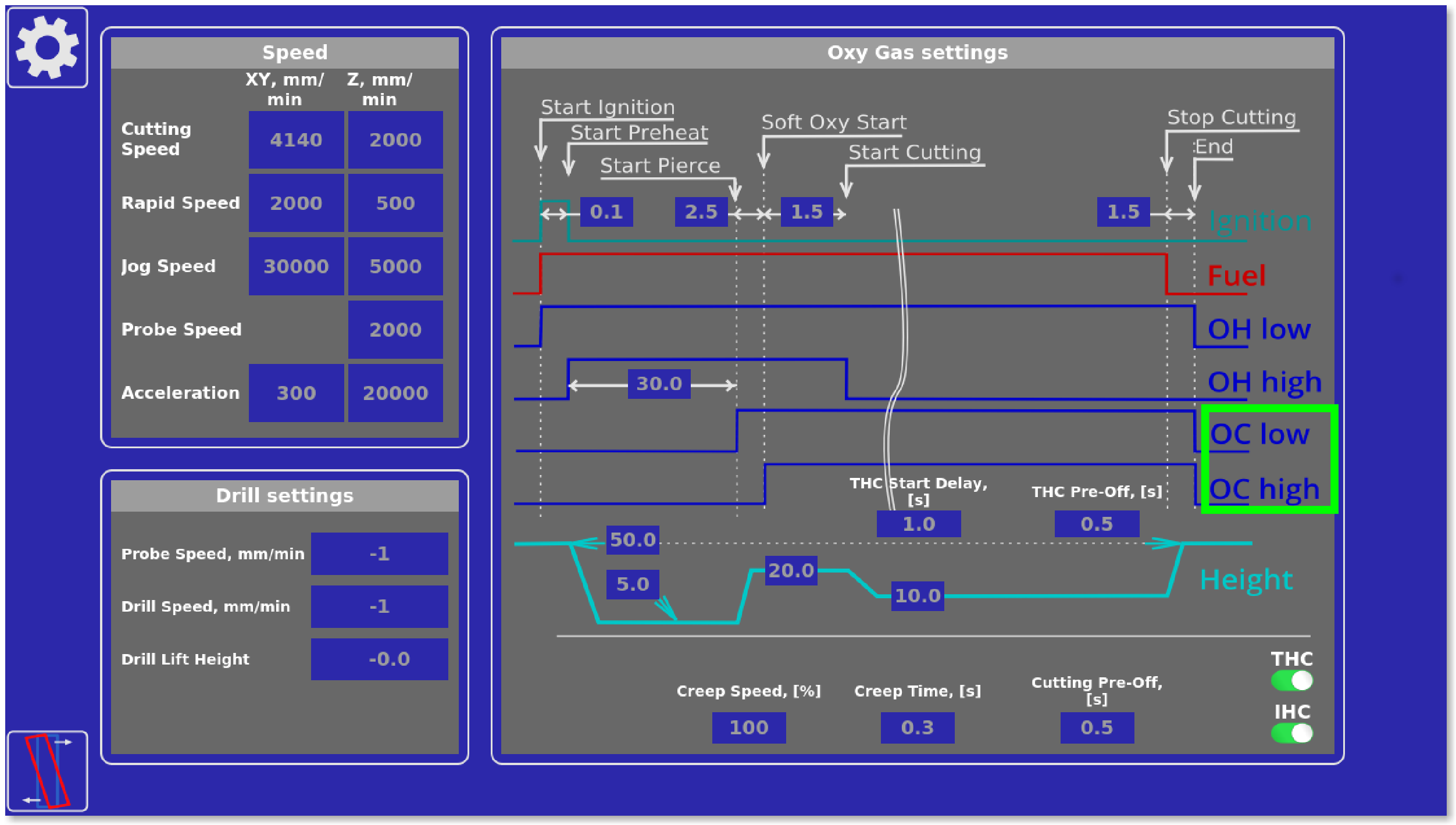

Upon opening the 1366G profile (gas cutting/welding profile) and navigating to the User Settings, the operator is presented with the following window:

This graph describes the behaviour of the gas that is being supplied to the oxy-fuel cutting torch. Depending on the torch setup the user has, the torch can have connections to an Ignition cycle, a Fuel flow, a Heating Oxygen (OH) flow at low and high pressures, as well as a Cutting Oxygen (OC) flow at low and high pressures. It is entirely possible, for example, to only have one Heating Oxygen pressure, or one Cutting Oxygen pressure if the machine is so configured.

Going through the graph, the following behaviour can be specified:

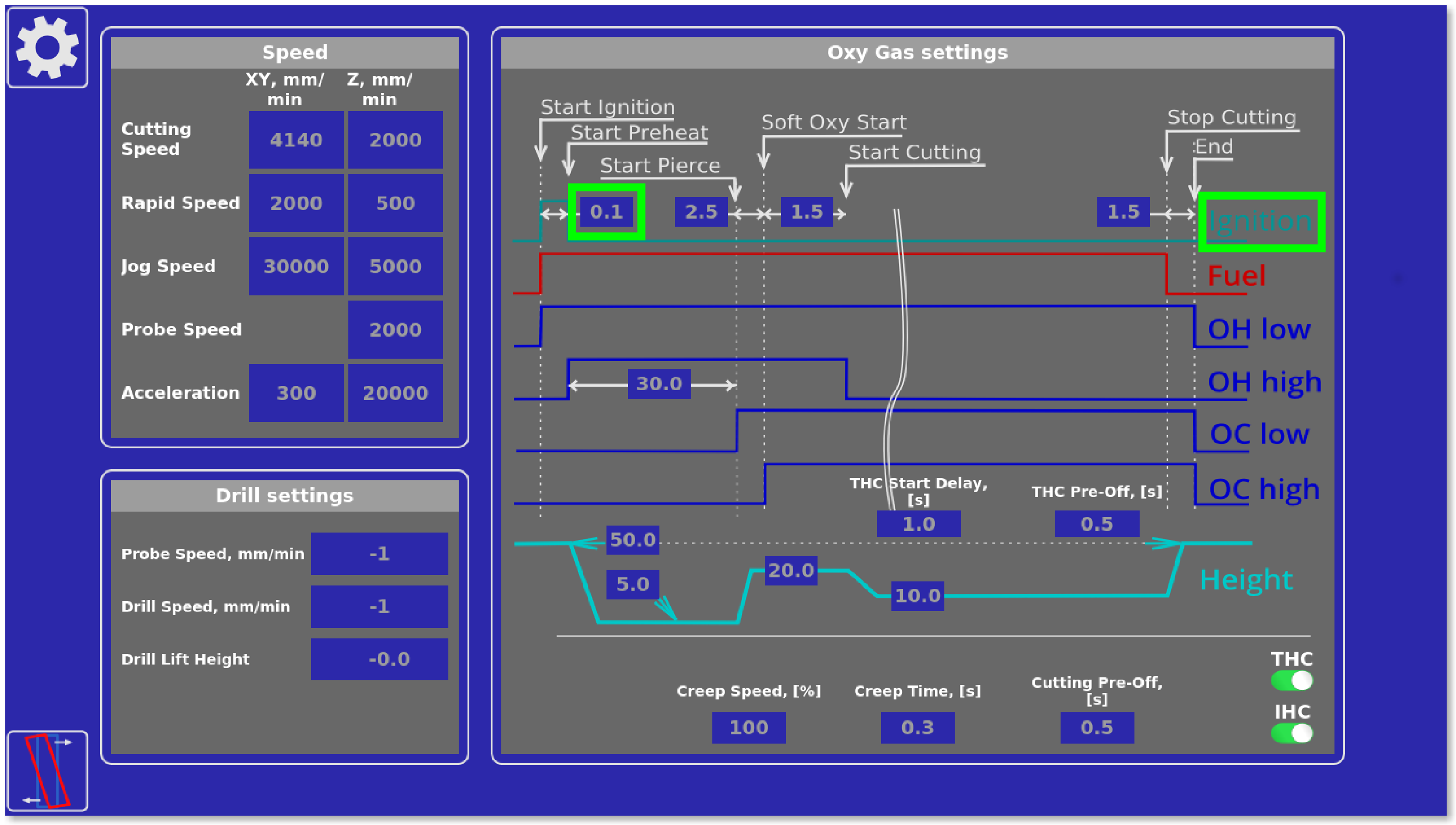

Ignition

The ignition cycle serves to ignite the heating fuel/oxygen mix before the cutting begins. It is usually done by using an ignition torch, which is supplied with its own fuel flow at low pressure. After the signal is sent from the controller, this low-pressure fuel in the ignition torch is ignited, and comes into contact with the heating oxy-fuel flow from the main torch, igniting it in turn. This is done in order to prevent a direct ignition of the heating oxy-fuel flow which is usually at a much higher pressure than that of the ignition torch.

Note: The ignition cycle can be foregone altogether if the user does not have an ignition torch and can ignite the oxy-fuel manually.

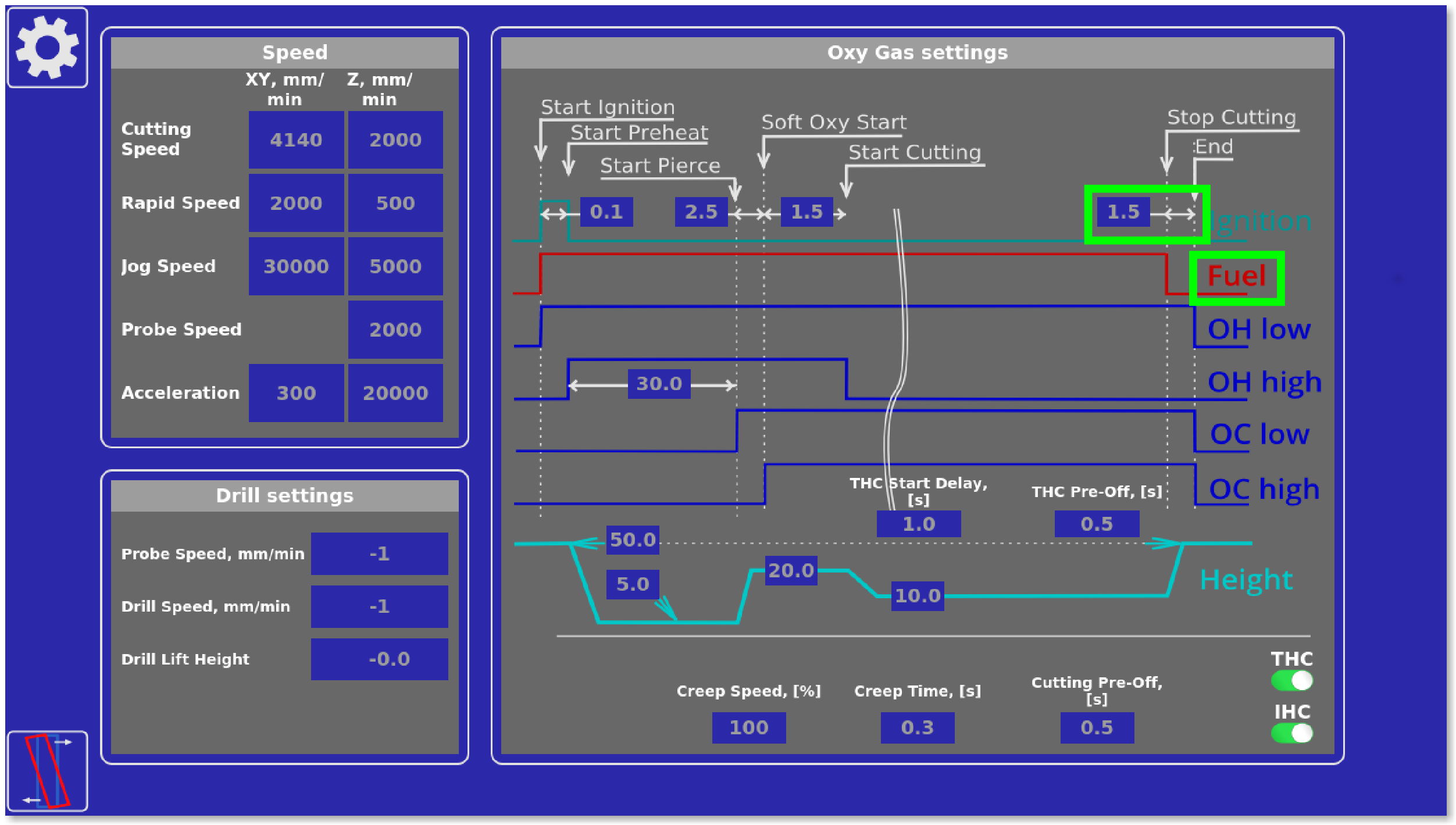

Fuel

The fuel flow to the main torch is started as soon as the ignition signal is sent to the ignition torch. Note that the fuel flow can be stopped slightly earlier than the oxygen flow (1-2 seconds earlier), as to prevent fuel accumulation at the end of the process which may result in an explosive hazard.

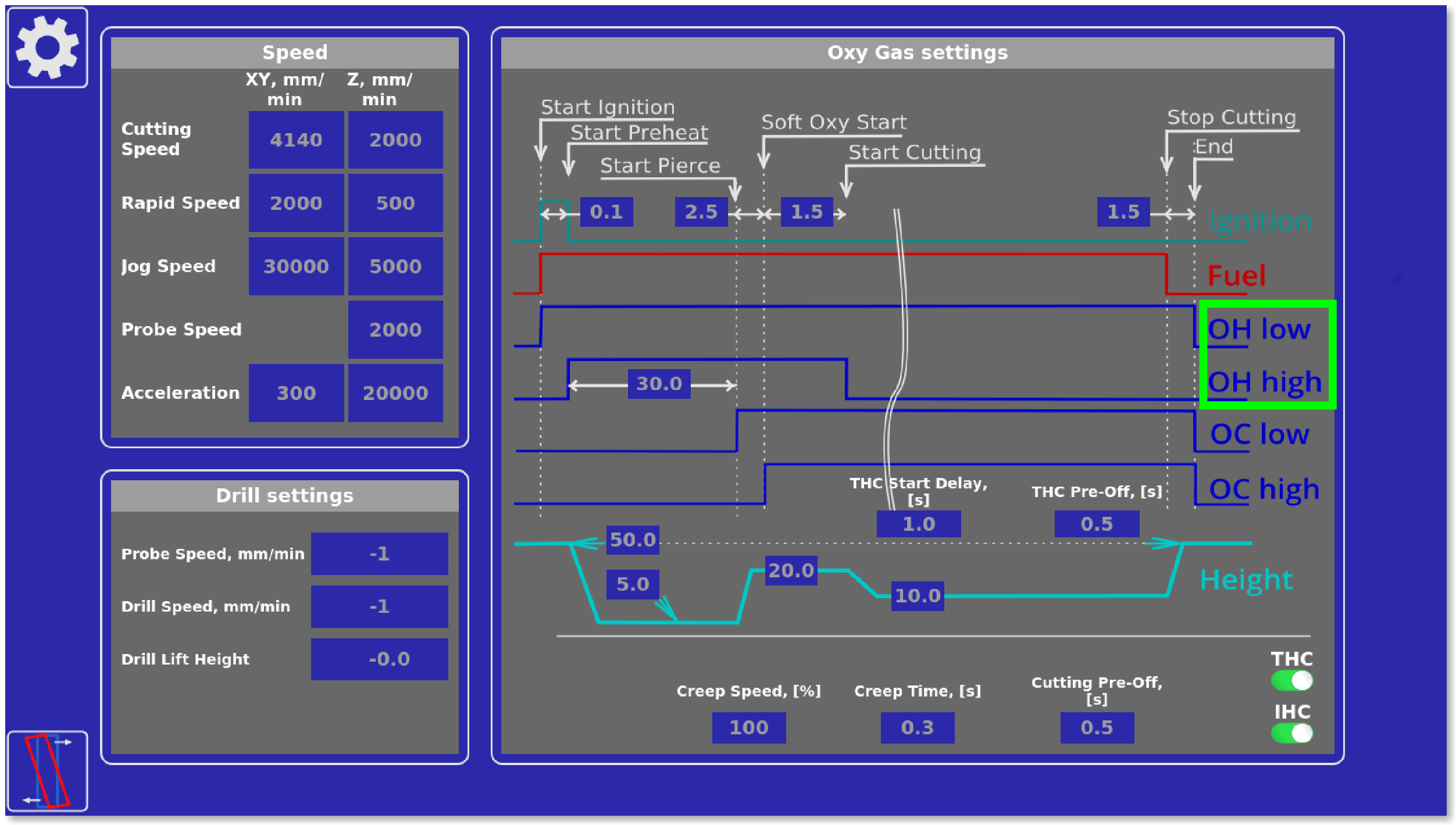

OH low and OH high

OH Low describes the behaviour of low-pressure heating oxygen. The low-pressure oxygen flow begins with the fuel flow. Note that if only one heating oxygen flow is available, OH low connection should be used when setting up the machine.

OH High describes the behaviour of high-pressure heating oxygen. Note that the high-pressure oxygen is supplied to the machine at a slight delay after the low-pressure heating oxygen, in order to prevent a sudden shock to the system.

OC low and OC high

OC low is the low-pressure cutting oxygen flow. It is started slightly before the OC high (high-pressure cutting oxygen) flow as to prevent the heated metal from splashing onto the torch. Note that if only one cutting oxygen flow is available, OC low connection should be used when setting up the machine.

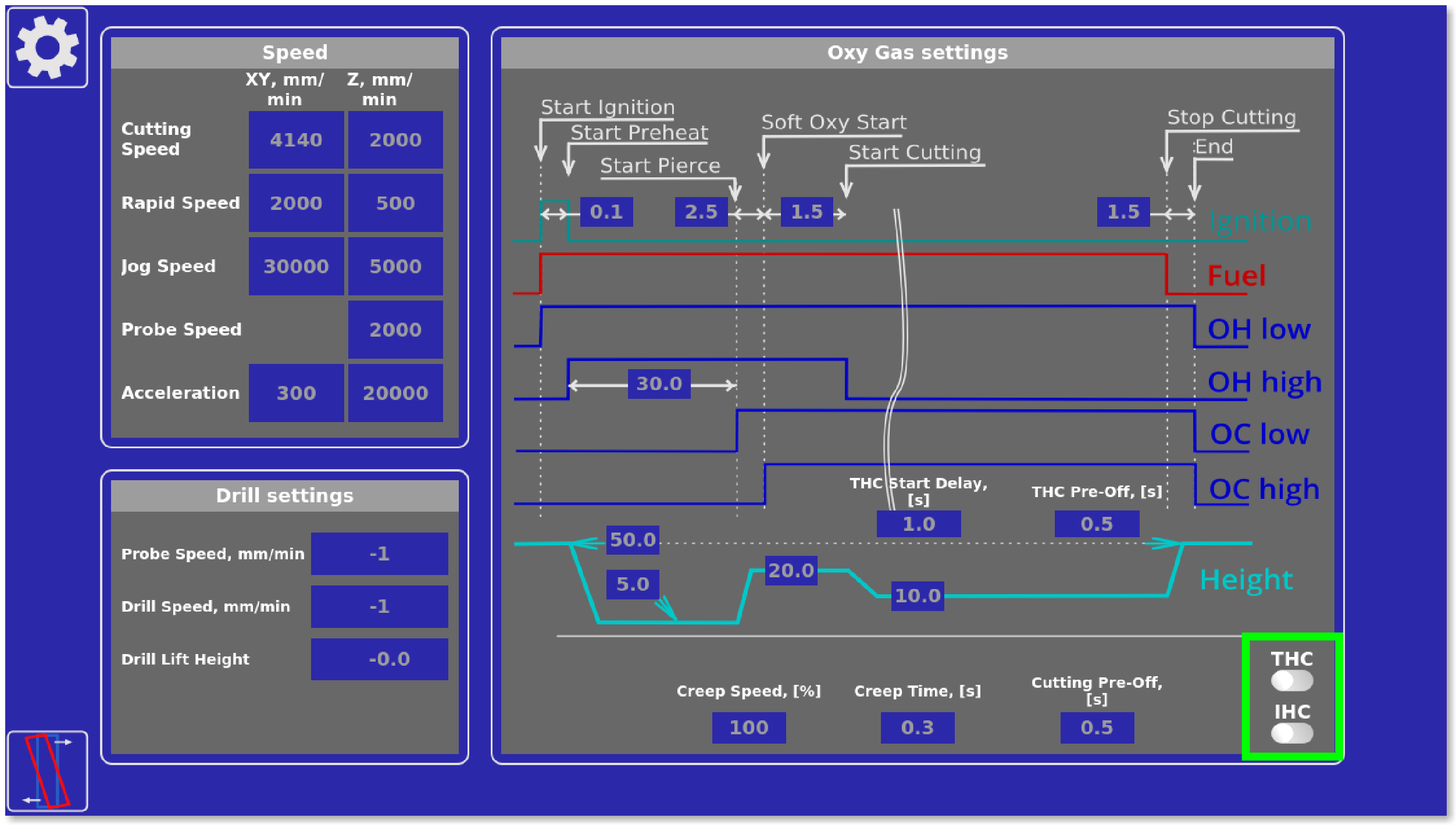

THC and IHC

On most machines, THC and IHC are usually not required for the operator, so these should be turned off by default:

Start/Stop Setup

For proper oxyfuel cutting start, it is necessary to set the Direct Move option in Start/Stop settings. Failure to do so may result in incorrect behaviour for certain procedures, such as Cutting from Edge:

Controller Output Connections

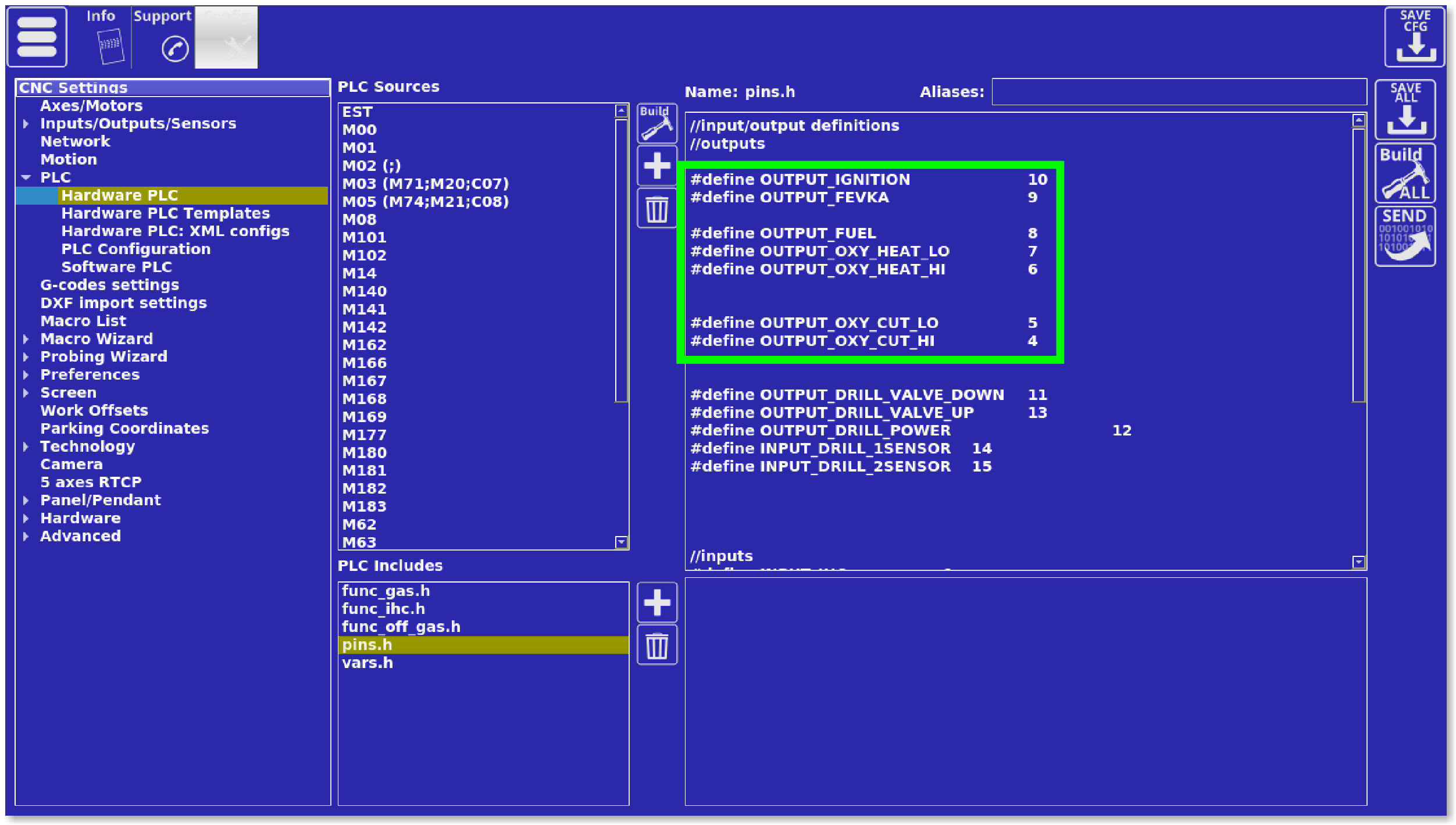

In order to check the proper output connections for connecting the controller to the machine setup, go to Settings > PLC > Hardware PLC > pins.h. The current output configuration can be found on the screen such as the one presented to you below:

As can be seen here, the following outputs are currently assigned:

| OUT4 | Cutting Oxygen (high pressure) |

| OUT5 | Cutting Oxygen (low pressure) |

| OUT6 | Heating Oxygen (high pressure) |

| OUT7 | Heating Oxygen (low pressure) |

| OUT8 | Fuel |

| OUT9 | Ignition Torch (fevka) -starts gas flow to ignition torch |

| OUT10 | Ignition (spark) |

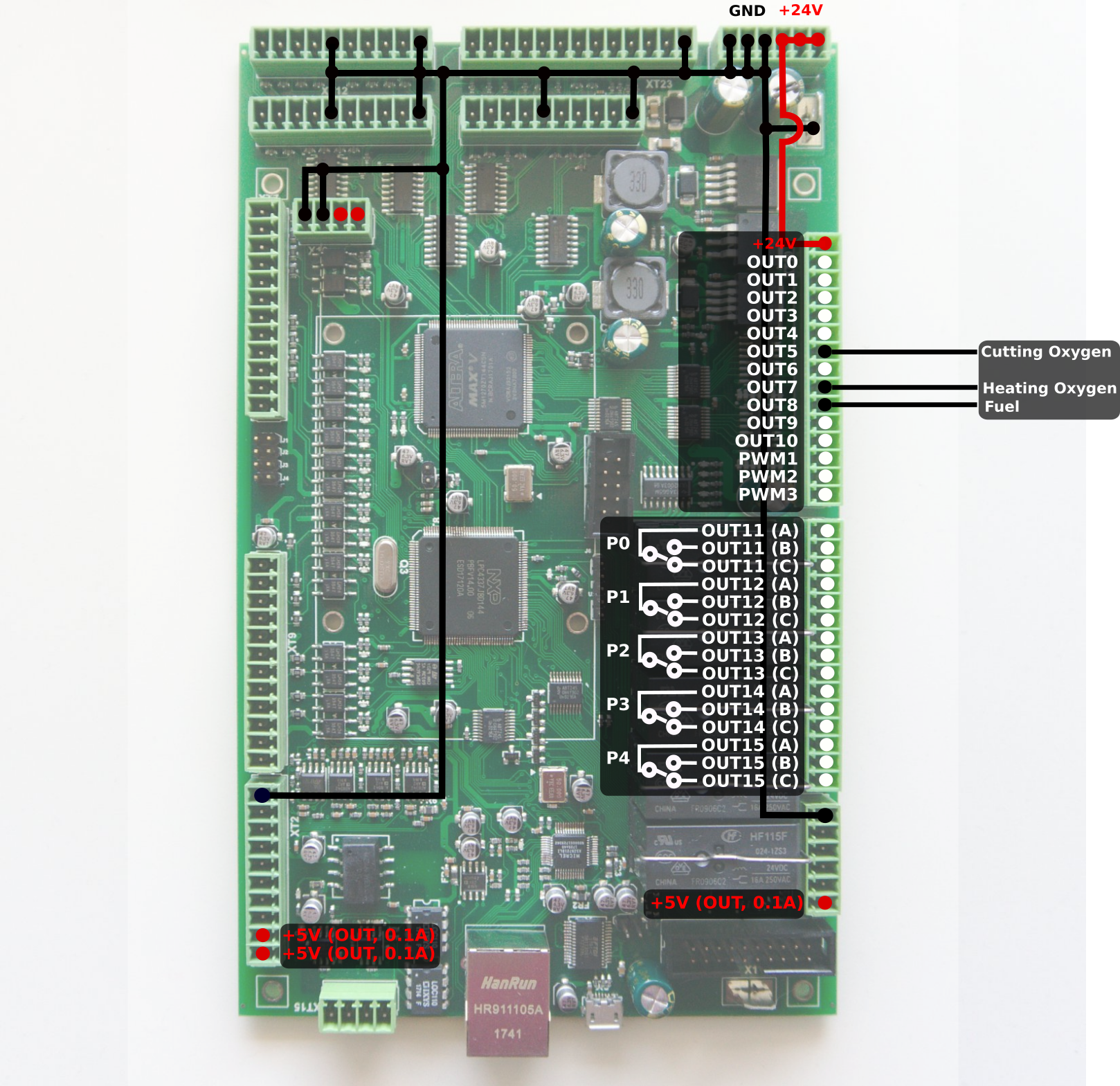

Every one of these outputs can be reconfigured if the user so desires. However, in this default configuration, connecting the controller to the machine looks as follows:

Simpler Controller Connections

Note that the image above refers to a full configuration for an oxy-fuel cutting machine equipped with all the possible oxygen flows as well as an ignition cycle. A simpler machine connection configuration with only one pressure of cutting and heating oxygen, a fuel supply and no ignition torch will look as follows: