Table of Contents

MQL - Minimum Quantity Lubrication

myCNC software allows the user to implement MQL, or Minimum Quantity Lubrication, on their machines.

MQL is a process in which tiny drops of high-quality aerosol lubricant are sprayed over the cutting tool and the material, providing lubrication at extremely low rates of lubricant use. This allows for a greatly reduced fluid usage (with the workpiece being nearly dry throughout the lubrication process) as opposed to typical flood setups, resulting in a greener environmental impact and eliminating the need for fluid disposal.

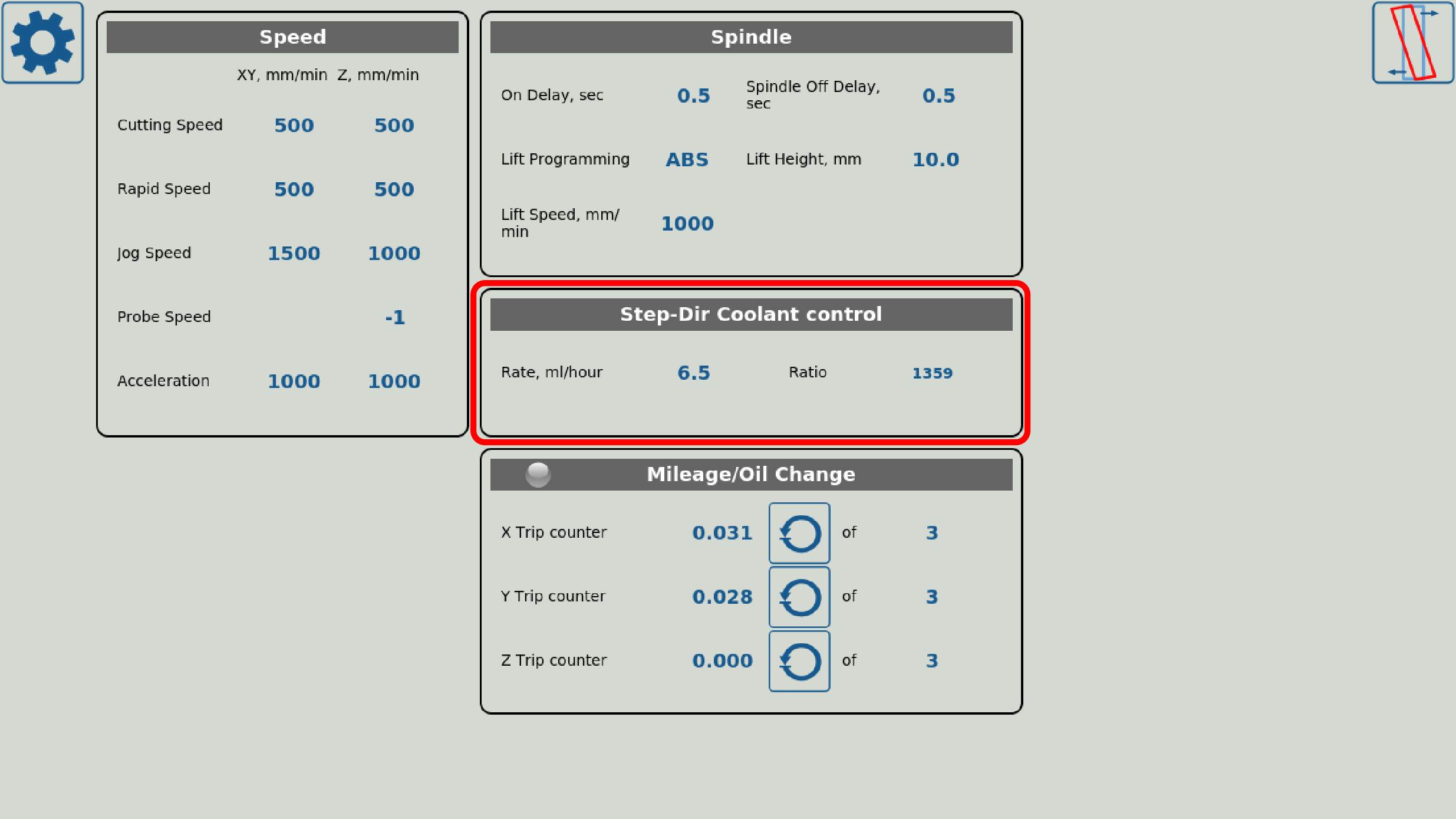

MQL is available in myCNC software by going into the Step/Dir Coolant control tab within User Settings, where you can set the coolant rate.

The fine-tuning is done through the built-in PLC procedures, with the setup described in detail in the Independent Pulse Generator manual.

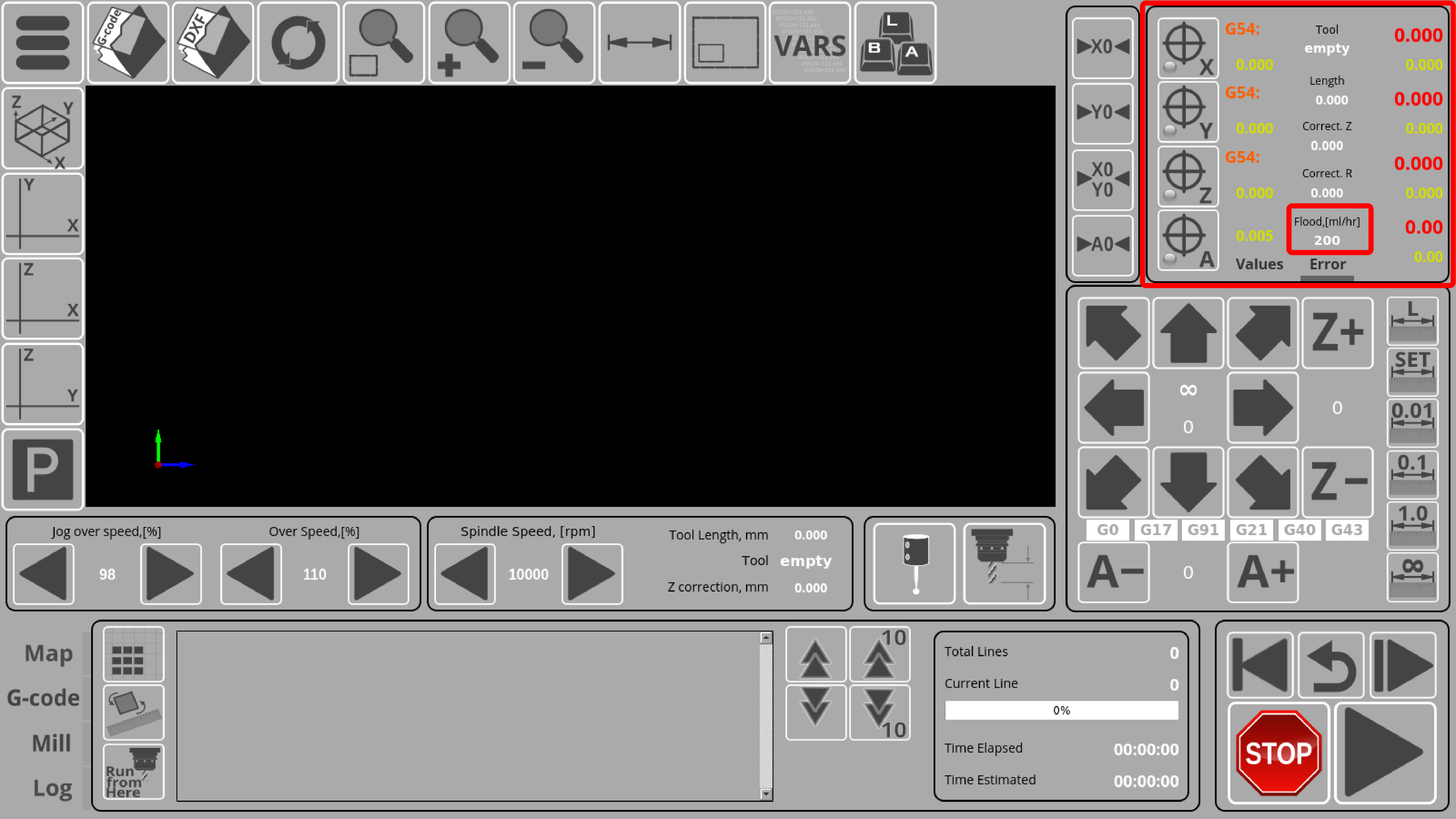

In certain profiles (such as the X1366M4E), the MQL functionality is accessible via the main myCNC screen (in the Coordinates section):

This on-screen element displays the current Flood Coolant Rate (global variable #8133).

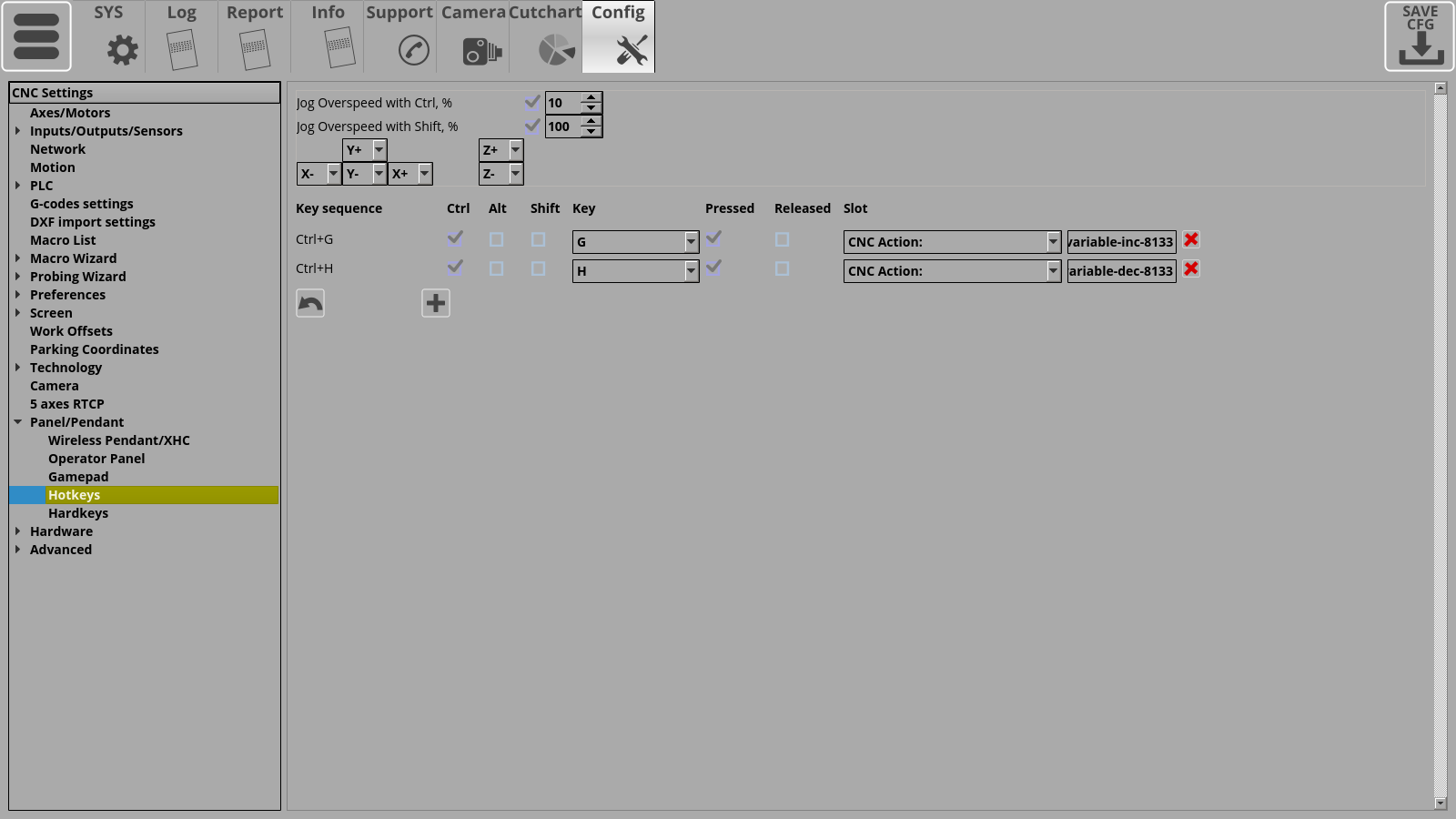

A series of hotkeys can also be assigned within the myCNC software to quickly control the flood rate. This can be done by going into Settings > Config > Panel/Pendant > Hotkeys, and assigning two new keyboard shortcuts with the following actions:

cnc-gvariable-inc-8133

and

cnc-gvariable-dec-8133

The following screenshot shows an example configuration of two key bindings to increase and decrease the flood rate:

This will allow the user to quickly change the coolant flood rate from their keyboard.

MQL Setup in myCNC software

This section has been copied from the Independent Pulse Generator manual linked above.

Software PLC for MQL

The rate, ratio and acceleration can be set up in the Software PLC, as well as in the User Settings widget (the Step-Dir Coolant Control section).

“HANDLER_INIT.plc” procedure is started just after the configuration is sent to the myCNC controller. A few lines to set up the Frequency generator can be added there.

Hardware PLC for MQL

In addition to the software HANDLER_INIT PLC, certain hardware PLC procedures must be changed for the Minimum Quantity Lubrication to be set up.

Function coolant_motor_start() is added to the mill-func.h file:

M08.plc procedure which starts the coolant motor would be the following (note the inclusion of mill-func.h at the beginning of the code):

A procedure M09.plc to stop a coolant motor is simpler - we simply need to write “0” to the raw frequency register.

This concludes the software setup for MQL within the myCNC software.