Table of Contents

PLC

PLC stands for “Programmable Logic Controller”.

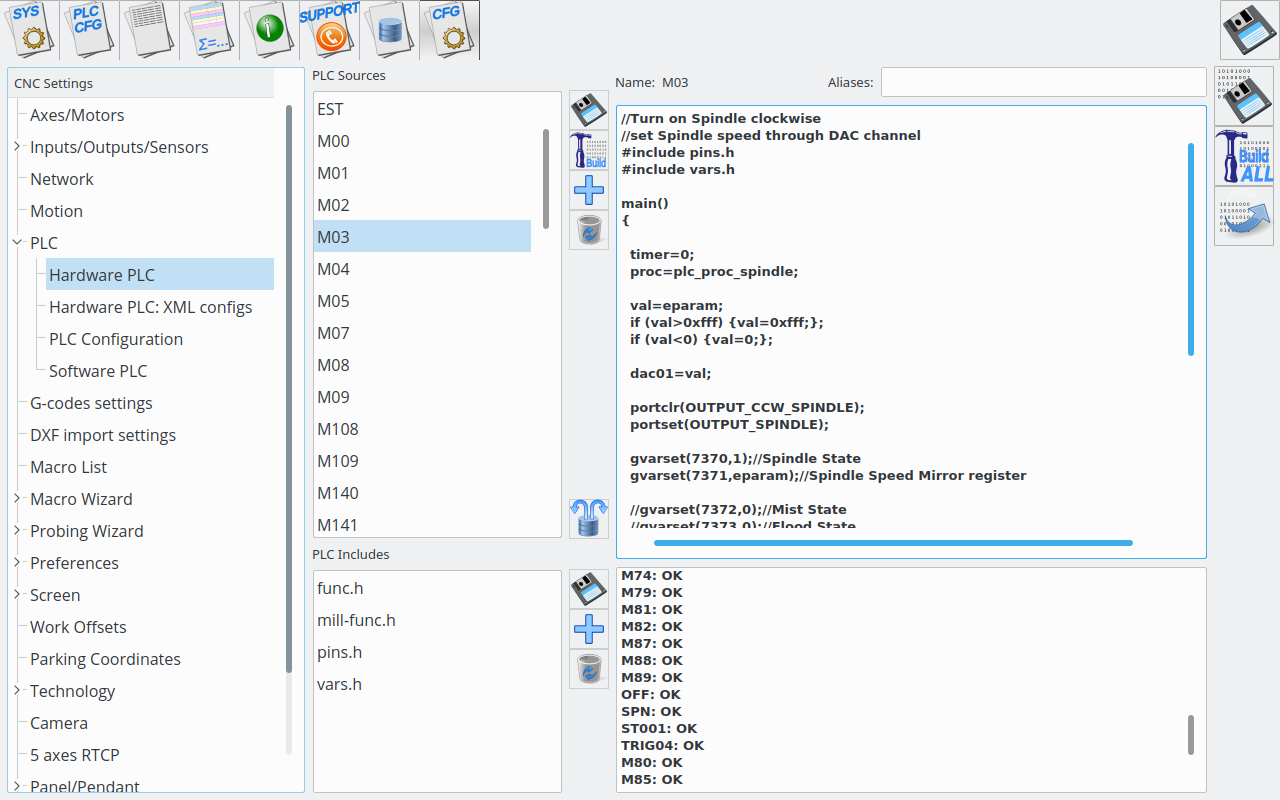

PLC controller can load and run small binary programs (PLC procedures). PLC procedure should be written in a simplified C-like language, compiled and stored in PLC controller memory to be ready to run. myCNC software includes PLC Builder - tiny IDE (Integrated Development Environment) to create and modify PLC procedure source files, compile them to binary code and upload it as RomFS iso image disk to PLC controller memory.

myCNC control has 2 types of built-in PLC systems that named Hardware PLC and Software PLC.

Note that hardware PLC can be launched from software PLC if necessary, through the use of gvarset(100040,HARDWAREPLC); command (replace HARDWAREPLC with your M-command of choice). You can read more on the process in the Software PLC section down below.

Hardware PLC

“Hardware PLC” means PLC system runs inside the CNC control board and able to access directly to CNC controller peripherals (inputs, outputs, PWMs, DACs, ADCs etc). PLC has also API to access to Motion Controller of a myCNC control board, so positioning commands are possible from Hardware PLC.

Hardware PLC is a tiny virtual machine that runs pre-compiled PLC procedures. PLC procedure can be started from

- G-code program M-code

- On-screen button

- Input Pin

- From TCP Ethernet Socket through Server API

Hardware PLC loop cycle time is 1ms. PLC core runs PLC procedure until the end of next loop. At the end of each loop PLC sleeps for 1ms, then continue running PLC. N-times repeat loop (even empty) will be executed N milliseconds. For example, delay for 10ms can be programmes as

timer=10; do{timer--;}while(timer>0);

IMPORTANT. Hardware PLC is single-tasking. Only one PLC process can be executed at the moment. If new PLC procedure loaded, previous PLC process will be terminated immediately and replaced by the new one.

PLC Language

- PLC operates with 32 bits integer values only. Floating point operations don't work in PLC (typically need to use coefficient conversions to allow for more granular control).

- There is no need to declare variables. There is very limited space of 32 elements for variables.

- There a number of pre-defined variables in the PLC

- eparam - External Parameter variable. A short manual is available here: Eparam

- proc - variable is used to identify a process running in the PLC.

The value is sent to the CNC control software and can be used to display Current PLC state (like Idle, Ignition (for plasma cutting), preheat (gas cutting), Tool change, Probing etc)- The proc variable can impact many behaviours of the myCNC software, such as jogging speed (using the User Settings value for when the proc is Idle, and using the cutting speed for Plasma and Cutting states).

- timer - value can be used as time counter inside PLC procedure

- vexit - variable contains additional exit code. In case of error CNC control software can display Error message depends on vexit exit code.

- message. The message variable is handled every loop delay time. If message value is not “0” PLC controller sends to CNC control software message code and reset the variable to “0”.

- pwm01 - variable mapped to PWM #0 register. Writing to this variable will change PWM #0 value.

- pwm02 - variable mapped to PWM #1 register. Writing to this variable will change PWM #1 value.

- pwm03 - variable mapped to PWM #2 register. Writing to this variable will change PWM #2 value.

- pwm04 - variable mapped to PWM #3 register. Writing to this variable will change PWM #3 value.

- dac01 - variable mapped to DAC #0 register. Writing to this variable will change DAC #0 value.

- dac02 - variable mapped to DAC #1 register. Writing to this variable will change DAC #1 value.

- adc01 - variable mapped to ADC #0 register. Reading this variable will return ADC #0 value.

- adc02 - variable mapped to ADC #1 register. Reading this variable will return ADC #1 value. Variables adc01, adc02 are a bit obsolete. It's better to use gvarget, gvarset functions and The hardware access registers to access to the control board peripherals.

For example, changing the value of PWM01 can be done using the following PLC procedure:

main()

{

val=eparam;

if (val>0xfff) {val=0xfff;};

if (val<0) {val=0;};

pwm01=val;

exit(99); //normal exit

};

PLC is a tiny virtual machine with a very limited register and memory space. PLC was created for very simple Inputs/Outputs manipulation. Heavy algorithms cannot be handled by PLC. Please keep in mind this while creating Hardware PLC procedure.

- PLC operators

| Operator | Description | Example |

|---|---|---|

+ | sum | c=a+200; |

- | subtract | c=a-150; |

* | multiply | c=a*b; |

/ | divide | c=b/7; |

& | logical AND | c=a&7; |

| | logical OR | c=b|1; |

>> | binary right shift | c=a>>16; |

<< | binary left shift | c=1<<n; |

== | equal to | if (a==20) ...... |

!= | not equal to | if (a!=0) ...... |

> | more than | if (b>0) ...... |

>= | more or equal than | if (a>=0xf) ...... |

< | less than | if (c<10) ...... |

<= | less or equal than | if (a<=b) ...... |

++ | variable post increment | x++; |

-- | variable post decrement | a--; |

- PLC functions

- g0moveA - send positioning command for PLC to the Motion controller.

- portset - set to “1” selected output pin

- portclear - clear to “0” selected output pin

- portget - return selected input pin state (“0”, “1”)

- gvarget - return Global Variable Register value. This function sends an inquiry about Global variable value to myCNC control software running on Host PC and waits till reply received. Waiting time can be 20…200ms depends on Host PC Operating System (Windows, Linux).

- gvarset - set Global Variable Register to given value. This function sends to myCNC control software inquiry to change Global Variable Register to given value. There is a number of “Mapped” register addresses besides of “real” Global Array registers. List of Mapped addresses is shown in a table below.

It is possible to access the state of the output via gvarget commands from within the PLC process:

a=gvarget(0x400); //OUT0 b=gvarget(0x407); //OUT7

Starting from 0x400 to represent OUT0, this is a hexadecimal system that is simple to convert to dotted decimals (through the likes of a simple reference site here). Thus, for example, gvarget(0x40d); will return the state of Output #13.

The hardware access registers

| Name | Address | Description |

|---|---|---|

| GVAR_HW_INPUTS0 | 7180 | |

| GVAR_HW_INPUTS1 | 7181 | |

| GVAR_HW_INPUTS2 | 7182 | |

| GVAR_HW_INPUTS3 | 7183 | |

| GVAR_HW_OUTPUTS0 | 7184 | YouTube tutorial |

| GVAR_HW_OUTPUTS1 | 7185 | |

| GVAR_HW_OUTPUTS2 | 7186 | |

| GVAR_HW_OUTPUTS3 | 7187 | |

| GVAR_HW_INPUTS4 | 7188 | |

| GVAR_HW_INPUTS5 | 7189 | |

| GVAR_HW_INPUTS6 | 7190 | |

| GVAR_HW_INPUTS7 | 7191 | |

| GVAR_HW_OUTPUTS4 | 7192 | |

| GVAR_HW_OUTPUTS5 | 7193 | |

| GVAR_HW_OUTPUTS6 | 7194 | |

| GVAR_HW_OUTPUTS7 | 7195 | |

| GVAR_HW_ADC0 | 7196 | |

| GVAR_HW_ADC1 | 7197 | |

| GVAR_HW_ADC2 | 7198 | |

| GVAR_HW_ADC3 | 7199 | |

| GVAR_HW_ADC4 | 7200 | |

| GVAR_HW_ADC5 | 7201 | |

| GVAR_HW_ADC6 | 7202 | |

| GVAR_HW_ADC7 | 7203 | |

| GVAR_HW_DAC0 | 7270 | |

| GVAR_HW_DAC1 | 7271 | |

| GVAR_HW_DAC2 | 7272 | |

| GVAR_HW_DAC3 | 7273 | |

| GVAR_HW_DAC4 | 7274 | |

| GVAR_HW_DAC5 | 7275 | |

| GVAR_HW_DAC6 | 7276 | |

| GVAR_HW_DAC7 | 7277 | |

| GVAR_HW_PWM0 | 7278 | |

| GVAR_HW_PWM1 | 7279 | |

| GVAR_HW_PWM2 | 7280 | |

| GVAR_HW_PWM3 | 7281 | |

| GVAR_HW_PWM4 | 7282 | |

| GVAR_HW_PWM5 | 7283 | |

| GVAR_HW_PWM6 | 7284 | |

| GVAR_HW_PWM7 | 7285 |

Software PLC

“Software PLC” means PLC system runs inside the myCNC software and controls CNC controllers peripherals through Software API.

The main advantage of Software PLC is multitasking. All PLC procedures are running simultaneously and independent from each other.

Software PLC cycle time is 100ms, so Software PLC is suitable for wide range of slow applications like automatic lubricant control, fume exhaust control, alarm sensors control etc.

- All Software PLC procedures (except “system” procedures) are compiled and started simultaneously in separate threads with myCNC software start or after “Build All” button pressed in PLC Builder/Software PLC.

- “System” PLC procedures are procedures with names start with

__ (double underscore)

symbols. “System” procedures are not started automatically with the myCNC software start, but instead can be started automatically with some events or manually. There are a few pre-defined “System” PLC handlers-

| Handler Name | Comments |

|---|---|

__HANDLER_INIT | The procedure executed just after myCNC software started AND configuration is sent to the myCNC control board. The procedure can be used to perform some inputs testing and switch outputs just after the software started. |

__HANDLER_EXIT | The procedure executed just before the myCNC software closed. |

__HANDLER_GCODE_START | The procedure executed just before the myCNC software run g-code (after pressing PLAY button) |

__HANDLER_GCODE_STOP | The procedure executed just after the myCNC software finished g-code running (after pressing STOP/PAUSE button) |

__BV17 | Initially named BV17, this Software PLC had double underscores added to remove an issue with automatic enabling of the testing mode for the controller peripherals (by becoming a System PLC, it prevents the procedure from starting automatically when the program is loaded). |

Variables used in Software PLC:

| Variable | Use | Example | Comment |

|---|---|---|---|

| 100020 | Jog the selected axis (100020 through to 100027) | gvarset(100020, 100); | Negative values are not accepted, use 0-X (for example, gvarset(100020, 0-100);) |

| 100040 | Launch a Hardware PLC from within a Software PLC | gvarset(100040, 607); | This will launch Hardware PLC M607 |

| 100041 | Eparameter to feed into the Hardware PLC being launched using 100040 | gvarset(100041, 333); | Used before gvarset(100040, 607);, this will set eparam=333 |

Compare Software and hardware PLC

| Parameter | Software PLC | Hardware PLC |

|---|---|---|

| Loop time | 100ms | 1ms |

| Hardware access | Slow, through the software and Ethernet communication | Fast, direct in myCNC controller |

| Multitasking | Yes, all PLC procedures are running simultaneously in separate threads | No, starting new procedure will terminate a current procedure |

| Code size for PLC procedure | 16k bytes | 512 bytes |

| Total disk size for PLC procedures | Unlimited | 8k bytes |

Language Core for Software and Hardware PLC are almost the same so language syntax is pretty the same and similar to C-language but VERY VERY stripped down.

PLC Language

PLC variables

- “32” - is a total number of variables PLC supports

- No need to define variables in source text. Variable name reserved when fist used. For example in line

output0=15;

PLC builder will define variable “output0” and assign the value to “15”

PLC predefined variables

- var00…var15 : This variables are initialised before PLC procedure start from values defined in plc-variables.xml file.

- proc : proc variable value can be displayed on myCNC screen with display name “display-plc-proc” and can be used to show current status of PLC procedure

- message : If message value set to non-zero value, PLC controller will send a message to myCNC Control Core or myCNC software with parameters defined in variables

message,

var00 (usually defined as command as well) and

var01 (defined as parameter).

This way PLC controller able to communicate with Motion Controller and Host Software. Message variable is handled and cleared by PLC controller while “loop” operation, so message variable assign usually followed by short timeout loop liketimer=2;do{timer--;}while(timer>0);Examples:

//send to myCNC software information spindle speed is "0" command=PLC_MESSAGE_SPINDLE_SPEED_CHANGED; parameter=0; message=PLCCMD_REPLY_TO_MYCNC; timer=2;do{timer++;}while (timer>0);

//Probing for Plasma Cutting. g0moveA(0x0,0x4,0-30000); //Start move down do { code=gvarget(6060); }while(code!=0); //Wait till Motion Controller confirm moving started do{ code=gvarget(6060); //check Motion Controller (MC) current status sens=portget(INPUT_IHC); //and check Probe input if (sens==0) { message=PLCCMD_LINE_STOP; //Send to MC command to Stop current line and wait next command code=1; //Set flag to exit from the loop }; }while (code==0); //Exit from loop is motion finished OR Probe sensor pressed

PLC defines

| Name | Value | Comment |

| PLCCMD_MOTION_CONTINUE | 1001 | |

| PLCCMD_MOTION_SKIP | 1002 | |

| PLCCMD_MOTION_SOFT_SKIP | 1003 | |

| PLCCMD_MOTION_PAUSE | 1004 | |

| PLCCMD_PLC_PAUSE | 1005 | |

| PLCCMD_PLC_FORK_PAUSE | 1006 | |

| PLCCMD_LINE_SOFT_STOP | 1007 | |

| PLCCMD_LINE_STOP | 1008 | |

| PLCCMD_REPLY_TO_MYCNC | 1100 | |

| PLCCMD_SET_CNC_VAR | 1010 | |

| PLCCMD_SET_THC_VAR | 1011 | |

| PLCCMD_SET_DEVICE_VAR16 | 1012 | |

| PLCCMD_SET_DEVICE_VAR32 | 1014 | |

| PLCCMD_SET_CNC_EXTVAR | 1020 | |

| PLCCMD_MOTION_ABORT | 1032 | |

| PLCCMD_MOTION_BREAK | 1033 | |

| PLCCMD_SAVE_POS | 1040 | |

| PLCCMD_THC_START | 1050 | |

| PLCCMD_THC_STOP | 1051 | |

| PLCCMD_THC_PAUSE | 1052 | |

| PLCCMD_THC_CONTINUE | 1053 | |

| PLCCMD_WATCHBIT1_ON | 1060 | |

| PLCCMD_WATCHBIT2_ON | 1061 | |

| PLCCMD_WATCHBIT3_ON | 1062 | |

| PLCCMD_WATCHBIT4_ON | 1063 | |

| PLCCMD_TRIGGER1_ON | 1060 | |

| PLCCMD_TRIGGER2_ON | 1061 | |

| PLCCMD_TRIGGER3_ON | 1062 | |

| PLCCMD_TRIGGER4_ON | 1063 | |

| PLCCMD_TRIGGER1_OFF | 1064 | |

| PLCCMD_TRIGGER2_OFF | 1065 | |

| PLCCMD_TRIGGER3_OFF | 1066 | |

| PLCCMD_TRIGGER4_OFF | 1067 | |

| PLCCMD_WATCHBIT1_OFF | 1064 | |

| PLCCMD_WATCHBIT2_OFF | 1065 | |

| PLCCMD_WATCHBIT3_OFF | 1066 | |

| PLCCMD_WATCHBIT4_OFF | 1067 | |

| PLCCMD_WATCHBIT5_ON | 1068 | |

| PLCCMD_WATCHBIT6_ON | 1069 | |

| PLCCMD_WATCHBIT7_ON | 1070 | |

| PLCCMD_WATCHBIT8_ON | 1071 | |

| PLCCMD_WATCHBIT5_OFF | 1072 | |

| PLCCMD_WATCHBIT6_OFF | 1073 | |

| PLCCMD_WATCHBIT7_OFF | 1074 | |

| PLCCMD_WATCHBIT8_OFF | 1075 | |

| PLCCMD_WAIT_FOR_CAMERA | 1090 | |

| PLCCMD_WAIT_VARSET | 1091 | |

| PLCCMD_WAIT_VARCLEAR | 1092 | |

| PLCCMD_CAMERA_START | 1093 | |

| PLCCMD_CAMERA_FINISH | 1094 | |

| PLCCMD_PLC_DEBUG | 1098 | |

| PLCCMD_PLC_RESTART | 1099 | |

| PLC_BROADCAST_INQUIRY0 | 1200 | |

| PLC_BROADCAST_INQUIRY1 | 1201 | |

| PLC_BROADCAST_INQUIRY2 | 1202 | |

| PLC_BROADCAST_INQUIRY3 | 1203 | |

| PLC_BROADCAST_INQUIRY4 | 1204 | |

| PLC_BROADCAST_INQUIRY5 | 1205 | |

| PLC_BROADCAST_INQUIRY6 | 1206 | |

| PLC_BROADCAST_INQUIRY7 | 1207 | |

| PLC_BROADCAST_INQUIRY8 | 1208 | |

| PLC_BROADCAST_INQUIRY9 | 1209 | |

| PLC_BROADCAST_INQUIRY10 | 1210 | |

| PLC_BROADCAST_INQUIRY11 | 1211 | |

| PLC_BROADCAST_INQUIRY12 | 1212 | |

| PLC_BROADCAST_INQUIRY13 | 1213 | |

| PLC_BROADCAST_INQUIRY14 | 1214 | |

| PLC_BROADCAST_INQUIRY15 | 1215 | |

| PLC_BROADCAST_OK | 1220 | |

| PLC_BROADCAST_ABORTED | 1221 | |

| PLCCMD_MODBUS_SPINDLE_SPEED | 1230 | |

| PLCCMD_MODBUS_SPINDLE_CMD | 1231 | |

| PLCCMD_SET_PIDTIME | 1240 |

Note on PLC define naming

Please note that there exist some limitations of the preprocessor that parses the #define lines. Specifically, it is not possible to have a full name of one parameter be part of the name of another parameter.

For example, an argument name such as OUTPUT_SPINDLE (present by default in the pins.h file), means that there must be no other define-names containing this substring. As such, names such as

OUTPUT_SPINDLE_COOL OUTPUT_SPINDLE_BEARING OUTPUT_SPINDLE_CONE

are NOT allowed, ssince they all contain the string “OUTPUT_SPINDLE”. Instead, you can make argument names such as

OUTPUT_BEARING_SPINDLE

or

OUTPUT_CONE_SPINDLE

since those do not contain the exact string from before. Failure to properly define your arguments in such a manner and then utilizing them in your PLC commands will result in a error during compilation with a label “syntax error, unexpected ID”.

PLCCMD_MOTION_CONTINUE and PLCCMD_MOTION_SKIP

The abovementioned PLCCMD_MOTION_CONTINUE and PLCCMD_MOTION_SKIP commands are highly useful for certain applications since typically the motion controller runs commands one by one. By design, if within a running program the next code is a PLC M-code, then the movement will be stopped and the controller will run the PLC program. A message from within the PLC called PLCCMD_MOTION_CONTINUE is used to instruct the Motion controller to read and run the next code from the buffer (thus starting the next motion command).

After this code, the PLC procedure continues running through its code while at the same time the next motion code is launched. In this way, both the PLC procedure and the motion command will be running simultaneously.

This is useful for applications such as homing since it makes it possible to both move the axis and monitor the home sensor in the PLC procedure at the same time. That way when the sensor is activated, the current movement command will need to be stopped. A different message called PLCCMD_MOTION_SKIP is then used - the motion controller will cancel current motion (it will stop moving) and will read the next code from the buffer.

PLC processes named

| PLC process name | Value | Comment |

| plc_proc_check_plasma | 10 | |

| plc_proc_venting | 11 | |

| plc_proc_start_power | 12 | |

| plc_proc_cooling | 14 | |

| plc_proc_plasma | 15 | |

| plc_proc_wait_plasma | 18 | |

| plc_proc_pierce | 27 | |

| plc_proc_no_plasma | 62 | |

| plc_proc_check_preflow | 16 | |

| plc_proc_check_cutflow | 17 | |

| plc_proc_check_gases | 23 | |

| plc_proc_test_out | 24 | |

| proc_m_function | 30 | |

| proc_zeroing | 32 | |

| plc_proc_probing | 33 | |

| plc_proc_ignition | 50 | |

| plc_proc_preheat | 51 | |

| plc_proc_soft_start | 52 | |

| plc_proc_piercing | 53 | |

| plc_proc_flame | 54 | |

| plc_proc_cutting | 60 | |

| plc_proc_purge | 61 | |

| plc_proc_no_cutting | 62 | |

| plc_proc_moveup | 65 | |

| plc_proc_spindle | 70 | |

| plc_proc_idle | 0 |

PLC exit codes list.

Normally PLC procedure should return code 99.

exit(99);

In case Error happened PLC procedure may return an error code. MyCNC software will catch exit code and report about Error if the error code is in PLC exit codes list.

| Exit code name | Value | Comment |

| plc_process | 0 | exit code is zero when PLC process is not finished yet |

| plc_exit_gas_fail | 2 | PLC aborted, No air pressure sensor |

| plc_exit_plasma_timeout | 3 | PLC aborted, No Arc sensor signal Timeout |

| plc_exit_plasma_fail | 4 | PLC aborted, PLC Plasma Start cutting procedure error |

| plc_exit_alarm_key | 5 | PLC aborted, Emergency key pressed |

| plc_exit_coolant_fail | 6 | PLC aborted, No Coolant flow sensor |

| plc_exit_probe_error | 7 | PLC aborted, No signal from probe sensor |

| plc_exit_motor_shorted | 8 | |

| plc_exit_broadcast_error | 10 | Error send broadcast message in multi-device configuration |

| plc_exit_normal | 99 | Normal exit |

| plc_exit_extern_break | 100 | PLC procedure aborted from outside of PLC core |

PLC messages

| Message name | Value | Comment |

| PLC_MESSAGE_PLASMA_OK | 101 | |

| PLC_MESSAGE_WATCHBIT_ACTION | 110 | |

| PLC_MESSAGE_SPINDLE_SPEED_CHANGED | 120 | |

| PLC_MESSAGE_PULL_OUT_TOOL | 130 | |

| PLC_MESSAGE_SPINDLE_TURNING 131 | ||

| PLC_MESSAGE_ENCODER_DATA | 140 | |

| PLC_MESSAGE_GVAR_VALUE | 141 | |

| PLC_MESSAGE_UID | 142 | |

| PLC_MESSAGE_HCONTROL_OFFSET | 144 | |

| PLC_MESSAGE_TANGENT_ANGLE | 145 | |

| PLC_MESSAGE_USER | 146 | |

| PLC_MESSAGE_HCONTROL_JSPEED | 147 | |

| PLC_MESSAGE_HCONTROL_DC | 148 | |

| PLC_MESSAGE_ASK_RECALC | 150 | |

| PLC_MESSAGE_SOFTLIMIT_STOP | 151 | |

| PLC_MESSAGE_GVARSET | 153 | |

| PLC_MESSAGE_IHC_NOT_CONNECTED | 155 | |

| PLC_MESSAGE_IHC_ERROR | 156 | |

| PLC_MESSAGE_LATHE_GEARS | 160 | |

| PLC_MESSAGE_ERR_VM | -1 | |

| PLC_MESSAGE_ERR_ROMFS | -2 | |

| PLC_MESSAGE_MOTION_BUFFER_EMPTY | -5 | |

| PLC_MESSAGE_ERR_SENSOR_COOLANT | -10 | |

| PLC_MESSAGE_ERR_SENSOR_AIR | -11 | |

| PLC_MESSAGE_ERR_SENSOR_GAS | -12 | |

| PLC_MESSAGE_ERR_SENSOR_OXYGEN | -13 | |

| PLC_MESSAGE_ERR_SENSOR_PLASMA | -14 | |

| PLC_MESSAGE_ERR_PROBING | -15 | |

| PLC_MESSAGE_ERR_PLASMA_FAIL | -20 | |

| PLC_MESSAGE_ERR_PLASMA_TIMEOUT | -21 | |

| PLC_MESSAGE_PRESSED_ALARM_KEY | -30 | |

| PLC_MESSAGE_PRESSED_STOP_KEY | -31 | |

| PLC_MESSAGE_MOTOR_SHORTED | -35 |

| MAPPED_OUT_THC_LOWSPEED | 63 | |

| MAPPED_OUT_LOW_MOTOR_CURRRENT | 65 |

Controller peripherals API from PLC procedures

A number of Global variable addresses are mapped to Hardware Inputs/Outputs. PLC procedure can access the controller peripherals through GVarGet/GVarSet function. Addresses to access to controller hardware are listed below

| Variabe Name | Address | Description |

|---|---|---|

| GVAR_HW_INPUTS0… GVAR_HW_INPUTS3 | 7180… 7183 | |

| GVAR_HW_OUTPUTS0… GVAR_HW_OUTPUTS3 | 7184… 7187 | |

| GVAR_HW_INPUTS4… GVAR_HW_INPUTS7 | 7188… 7191 | |

| GVAR_HW_OUTPUTS4… GVAR_HW_OUTPUTS7 | 7192… 7195 | |

| GVAR_HW_ADC0… GVAR_HW_ADC7 | 7196… 7203 | |

| GVAR_HW_DAC0… GVAR_HW_DAC7 | 7270… 7277 | |

| GVAR_HW_PWM0… GVAR_HW_PWM7 | 7270… 7277 | |

| GVAR_ET5_ENCODER … | ||

| GVAR_ET5_ENCODER_Z … | ||

| GVAR_ET5_ENCODER_WZ … | ||

| GVAR_ET5_ENCODER … | ||

| GVAR_MODBUS_READ | ||

| GVAR_THC0_CONTROL | 7570 | |

| GVAR_THC1_CONTROL | 7575 | |

| GVAR_CURRENT_MOTION_CODE | 6060 | |

| GVAR_MD_MASTER_MOTION_CODE | 7140 | |

| GVAR_CURRENT_TOOL_NUMBER | 5400 | |

| GVAR_HCONTROL2_VREF | ||

| GVAR_PLC_MOVE_PROCESS | ||

| GVAR_CAMERA_READY | 7090 | |

| GVAR_CURRENT_MACHINE_POSITION | 5021, 5022, 5023, 5024, 5025, 5026 | |

| GVAR_CURRENT_PROGRAM_POSITION | 5041, 5042, 5043, 5044, 5045, 5046 | |

| GVAR_ENCODER_Z_EVENT | ||

| — | 17001 | Return Current PROGRAM X Position in PLC units (0.01mm) |

| — | 17002 | Return Current PROGRAM Y Position in PLC units (0.01mm) |

| — | 17003 | Return Current PROGRAM Z Position in PLC units (0.01mm) |

| — | 17004 | Return Current PROGRAM A Position in PLC units (0.01degree) |

| — | 17005 | Return Current PROGRAM B Position in PLC units (0.01degree) |

| — | 17006 | Return Current PROGRAM C Position in PLC units (0.01degree) |

| — | 17007 | Return Current PROGRAM U Position in PLC units (0.01mm) |

| — | 17008 | Return Current PROGRAM V Position in PLC units (0.01mm) |

| — | 17009 | Return Current PROGRAM W Position in PLC units (0.01mm) |

| — | 17021 | Return Current MACHINE X Position in PLC units (0.01mm) |

| — | 17022 | Return Current MACHINE Y Position in PLC units (0.01mm) |

| — | 17023 | Return Current MACHINE Z Position in PLC units (0.01mm) |

| — | 17024 | Return Current MACHINE A Position in PLC units (0.01degree) |

| — | 17025 | Return Current MACHINE B Position in PLC units (0.01degree) |

| — | 17026 | Return Current MACHINE C Position in PLC units (0.01degree) |

| — | 17027 | Return Current MACHINE U Position in PLC units (0.01mm) |

| — | 17028 | Return Current MACHINE V Position in PLC units (0.01mm) |

| — | 17029 | Return Current MACHINE W Position in PLC units (0.01mm) |

Launching a PLC command using an on-screen button

The following video illustrates the process of creating a button to launch a software PLC command (a similar process can also be used for hardware PLCs):

Launching a Hardware PLC procedure from Software PLC

It is possible to launch Hardware PLC procedures from within a Software PLC command. This can be done for purposes such as utilizing certain commands are not available from the Software PLC, and that some require low-latency sensor monitoring. It also has the added benefit of utilizing the unlimited number of procedures that can work simultaneously in Software PLC, allowing the user create things such as permanent while loops, etc.

For example, a code such as:

main() { gvarset(100040,602); exit(99); };

will launch Hardware PLC M602 from the specified Software PLC.

Additionally, the Param variable can also be used to call a Hardware PLC with a certain eparam variable.

For example, adding a line such as

gvarset(100041, Param);

will launch the M602 Hardware PLC with the Param variable.

Jog from PLC

NOTE: Jog from PLC requires a firmware update. As of February 2022, the feature is available in the Testing firmware branch.

myCNC allows the user to call for a jog command from within PLCs. The advantage of this motion mode is that it allows to perform tasks (such as changing the speed and direction of movement, as well as turning the motion for a particular axis on or off), all without stopping. This is useful in such applications as homing along multiple (for example, three) axes. Such an example (with simultaneous positioning along the X and Y axes) is available here: PLC Examples

In this mode, the acceleration is set via the following command:

gvarset(8631,100); //acceleration time 100ms = 0.1s

while the speed is set via the global variable #8634 (the axis mask is stored in the high-order byte):

gvarset(8634,((1<<24)|1000)); //Jog speed for X gvarset(8634,((2<<24)|1000)); //Jog speed for Y gvarset(8634,((4<<24)|1000)); //Jog speed for Z

A sample motion code may therefore look the following way:

jog() { gvarset(8631,100); //acceleration time 100ms = 0.1s gvarset(5539,1); //switch to fast g0moveA implementation gvarset(8632,1000); //Jog Speed 1m/min gvarset(8634,((1<<24)|1000)); //Jog speed for X gvarset(8634,((2<<24)|1000)); //Jog speed for Y gvarset(8634,((4<<24)|1000)); //Jog speed for Z gvarset(8635,1); //Jog X+ timer=2000; do { timer--; if ((timer&0xff)==0) { gvarset(8635,1); }; }while(timer>0); gvarset(8634,((1<<24)|500)); //Speed 500 for X gvarset(8635,1); //Jog X+ timer=2000; do { timer--; if ((timer&0xff)==0) { gvarset(8635,1); }; }while(timer>0); gvarset(8634,((1<<24)|200)); //Speed 200 for X gvarset(8635,1); //Jog X+ timer=2000; do { timer--; if ((timer&0xff)==0) { gvarset(8635,1); }; }while(timer>0); gvarset(8635,2+1<<8); //Jog X- AND Y+ Simultaneously timer=2000; do { timer--; if ((timer&0xff)==0) { gvarset(8635,2+1<<8); //Jog X- AND Y+ Simultaneously }; }while(timer>0); gvarset(8635,0); };

The following variables may be used for this jog functionality:

| Variable name | Variable # |

|---|---|

| GVAR_G0PLC_SPEED | 8630 |

| GVAR_G0PLC_TIME | 8631 |

| GVAR_G0PLC_SPEED_UNITS | 8632 |

| GVAR_PLC_JOGSPEED_UNITS | 8634 |

| GVAR_PLC_JOG | 8635 |

An example of a homing PLC that utilized this functionality is shown below. This PLC is designed for the Z-axis only:

#include pins.h wait_move() { do { code=gvarget(6060); }while(code!=0x4d); //wait till motion finished }; show_error() { gvarset(9121,1); //bring up popup message 21 - this can be customized timer=50;do{timer--;}while(timer>0); message=PLCCMD_MOTION_BREAK; //1033 exit(99); }; find_home_z() { gvarset(5521,1); //disable hardware limits gvarset(5525,1); //disable software limits gvarset(8631,50); //acceleration time 100ms = 0.05s statez=0; //we set the "triggered" state to 0 by default speed=500; speed_slow=100; //used on rollback for better precision direction=(4<<8); //set the direction variable to Z- gvarset(8634,(4<<24)|speed); //Jog speed for Z gvarset(8635,direction); //jog in the set direction Z- timer=0; do { changed=0; if (statez==0) //to home X { sens=portget(INPUT_HOME_Z); //get state of home x sensor if (sens!=0) { statez=1; gvarset(8634,(4<<24)|speed_slow); //Jog speed for Z changed=1; }; }; if (statez==1) //rollback from home Z { sens=portget(INPUT_HOME_Z); //receive the state of the sensor if (sens==0) { statez=2; changed=1; }; }; if (changed!=0) //if any of the sensors state is changed { direction=0; //set direction to 0 (no movement) before flipping if (statez==0) { direction=direction | (4<<8); }; //direction set to X- if (statez==1) { direction=direction | 4; }; //direction set to X+ gvarset(8635,direction); //jog in new direction for the axes }; if ((timer&0xff)==0) { gvarset(8635,direction); }; timer++; ready=(statez==2); }while(ready==0); gvarset(8635,0); wait_move(); //stop jog }; main() { gvarset(8631,50); //acceleration time 50ms = 0.05s gvarset(5539,1); //switch to fast g0moveA implementation find_home_z(); exit(99); //normal exit };

The PLC above can be combined with the XY homing (linked at the start of this section) to create simultaneous XYZ homing. In general, the Jog from PLC functionality allows for this simultaneous movement, cutting down on the previously required separate procedures per each axis.