This is an old revision of the document!

Table of Contents

Plasma cutting profile 1366P

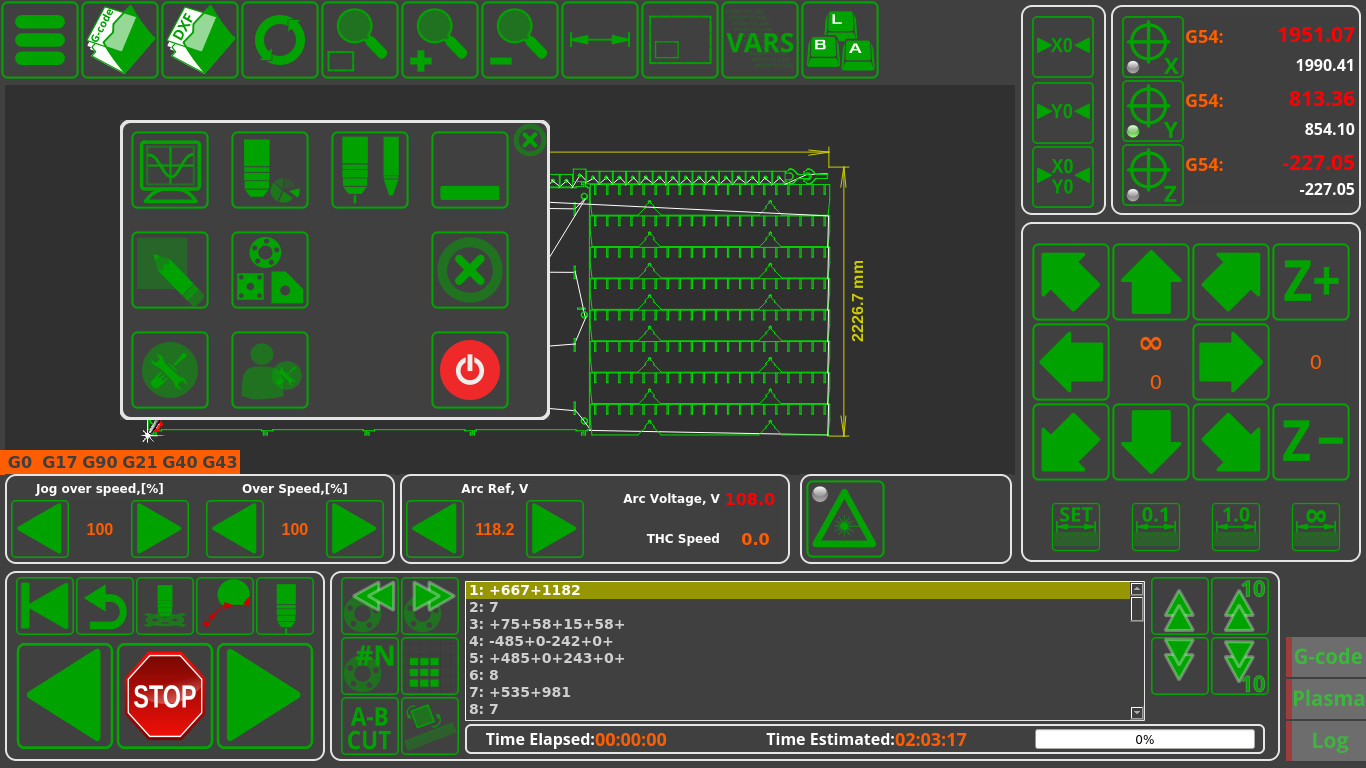

Upon loading myCNC software with the 1366P Plasma Cutting profile, you are presented with the following screen:

Main Screen buttons

| Run the homing for x-axis |

| Run the homing for y-axis |

| Run the homing for xy-plane |

| Reset to zero the working x-coordinate |

| Reset to zero the working y-coordinate |

| Reset to zero the working z-coordinate |

| Machine movement buttons (xy plane) |

| Machine movement button (positive z-axis) |

| Machine movement button (negative z-axis) |

| Set the machine movement step size to a specified value |

| Set the machine movement step size to 0.1 mm |

| Set the machine movement step size to 1 mm |

| Set an infinite machine movement step size |

Part selection and editing

Custom Machine Settings (User Settings)

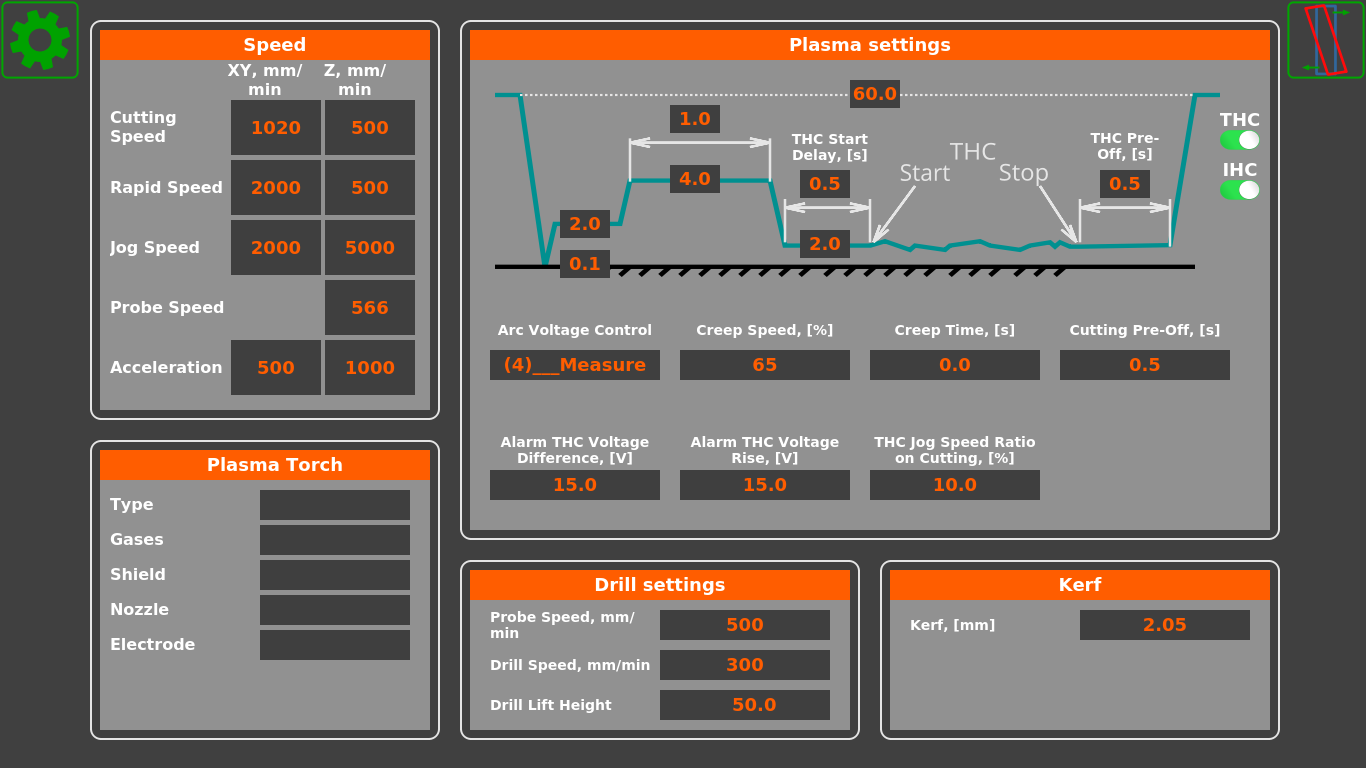

Upon opening the Custom Machine Settings for the 1366P profile, you are presented with the following screen:

This settings window allows to specify the distances within the plasma cutting cycle, as well as functions such as THC and IHC. It also serves as the quick settings window which is always accessible to the operator, as opposed to the general settings, which might be open or closed to the operator depending on the software configuration that the user decides to employ.

Progress bar

The progress bar for the control program is present in the latest versions of myCNC plasma cutting software.

The bar shows time elapsed, estimated time remaining for the entire program, and the percent progress bar for quick visual reference.

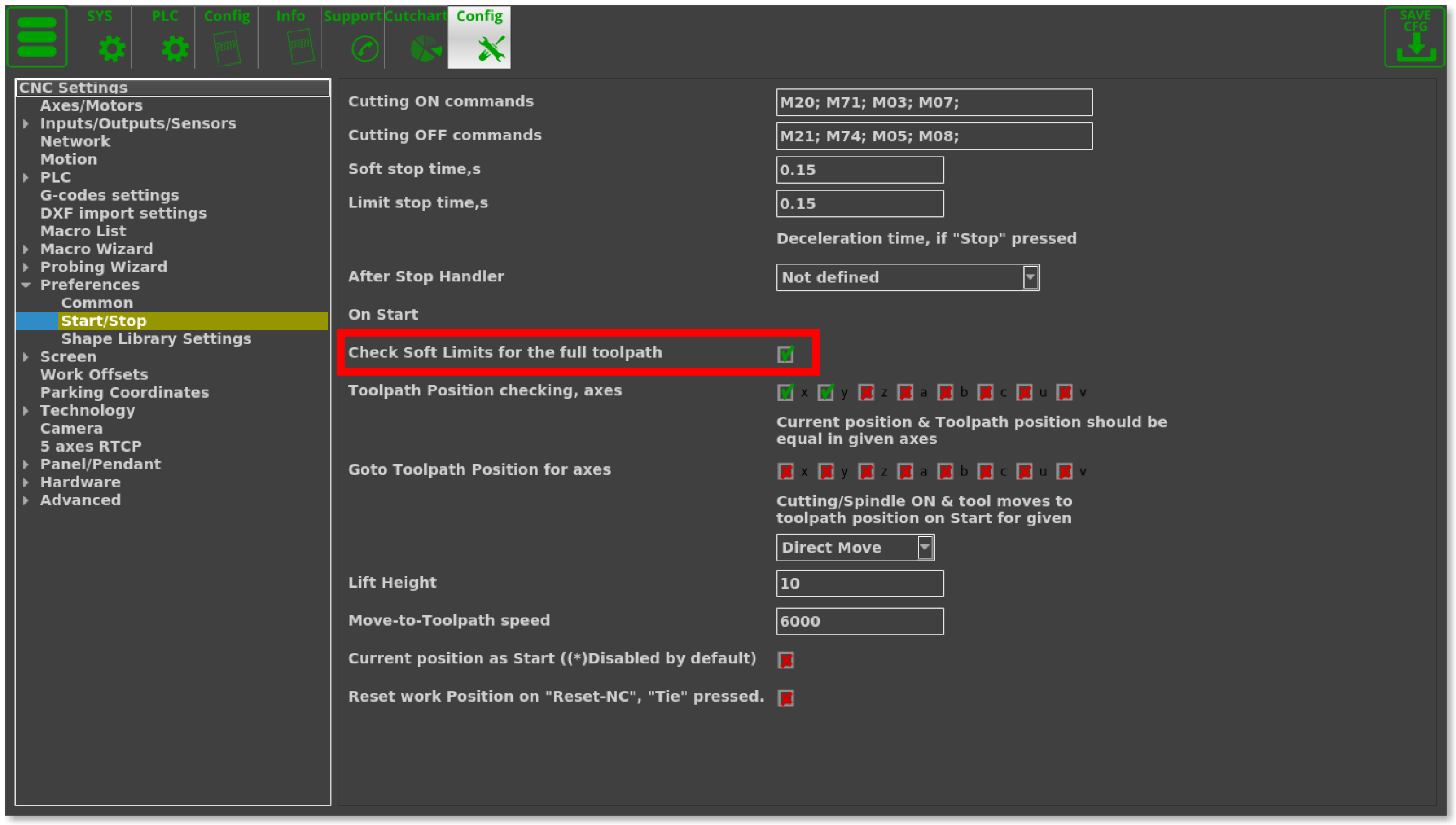

Note that the progress bar will only work properly if the following setting is turned ON: “Check Soft Limits for the full toolpath” in Settings > Preferences > Start/Stop.

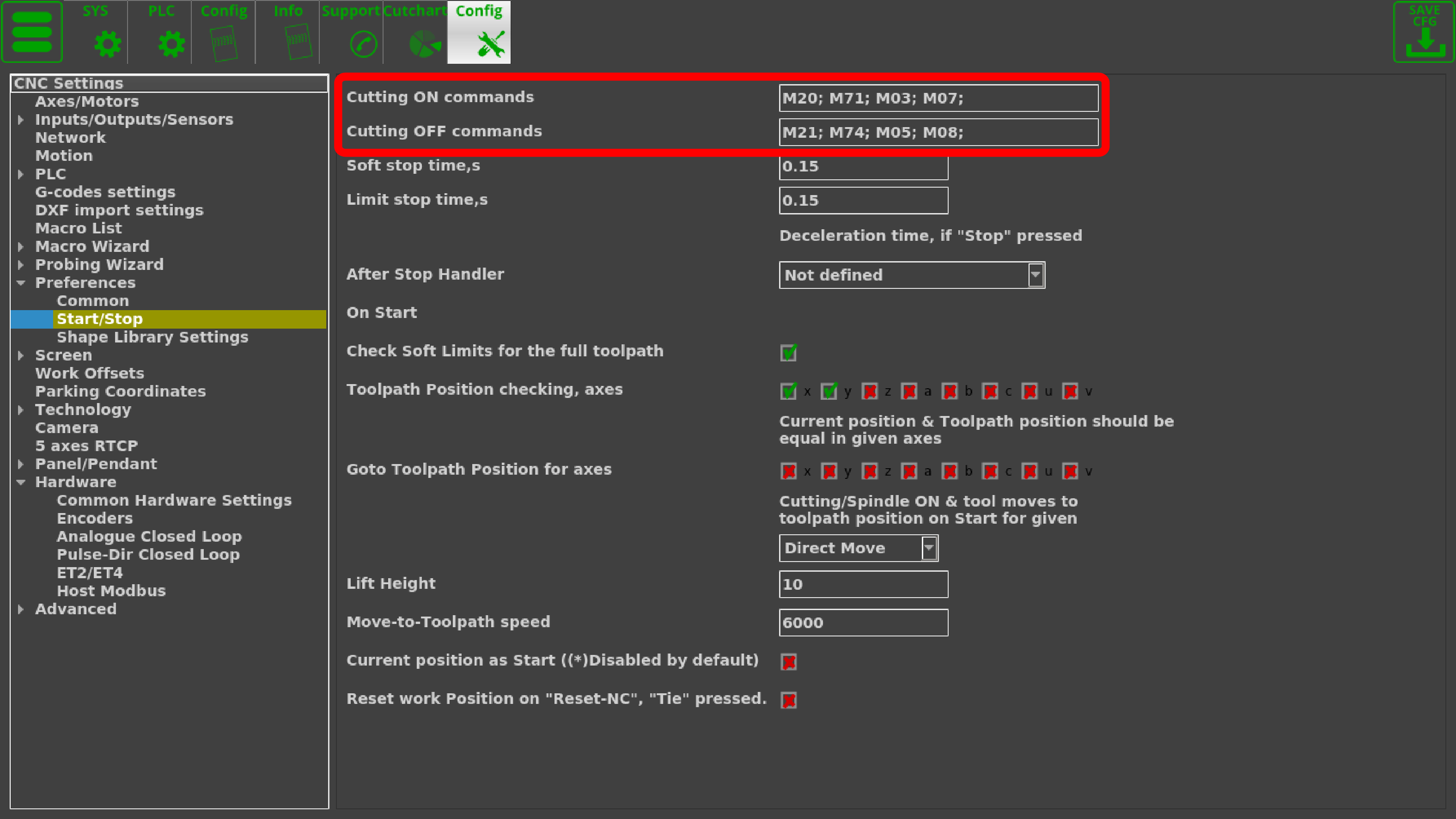

Simulation mode - ignore cutting commands

With the simulation mode turned ON, the software will ignore the cutting commands, simply moving the working bit (plasma torch, laser pointer, etc) around to give the user an option of running the program before the actual cutting begins. The commands which the myCNC software will ignore can be specified in the Settings > Config > Preferences > Start/Stop, as seen in the image below: