Table of Contents

myCNC-ET7 CNC controller

NOTE: The myCNC-ET9 controller (also labeled ET7R4, ET7R5 and ET7R6) is the updated version of the myCNC-ET7 board with some additional functionality. For information specific to the ET9 revisions, please consult the following manual: myCNC-ET9 (ET7 R4)

| myCNC-ET7 controller specifications | ||

|---|---|---|

| Number of motor outputs | 6 | |

| Motor driver outputs | pulse-dir, differential high-speed line driver outputs compatible with RS422 (TIA/EIA-422) standard | |

| Maximum pulse frequency | 3 MHz | |

| Binary inputs | 16x galvanic isolation, PNP/NPN sensor compatible | |

| Encoder inputs | 3x incremental encoder inputs,differential line driver (EIA RS422 compatible), hardware decoded, 5MHz max frequency | |

| Binary outputs | 5x - pluggable relays 10A, NO/NC contacts; 11x - open collector, 24V, 0.25A | |

| PWM outputs | 3x - open collector, 24V, 0.25A | |

| ADC inputs | 2x - 0…10V range, differential inputs, fully galvanic isolated (for plasma arc voltage measure, THC control), 6x - 0…3V range, non-isolated | |

| DAC output | 1x - 0…10V (for spindle speed control and relative applications) | |

| RS485/RS422 | 1x RS422 full duplex serial communication OR 2x RS485 half-duplex serial communication | |

| External operator panel connector | up to 25 external keys, up to 2 rotary encodersup to 2 double-axes joysticks OR up to 4 potentiometers (shared with 4x ADC inputs) | |

| Power supply outputs for control computer | 2x DC-DC converters 5V 1.5A | |

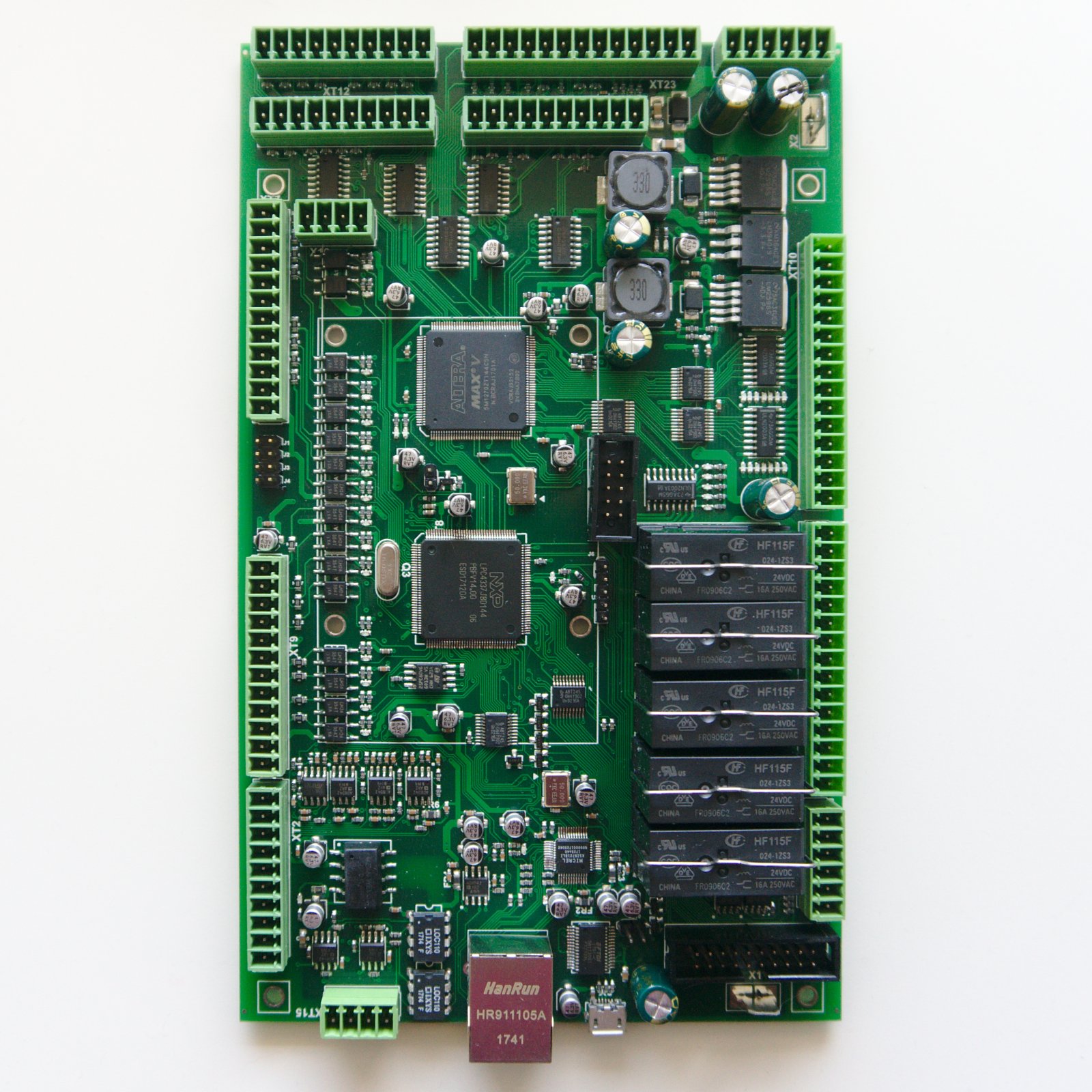

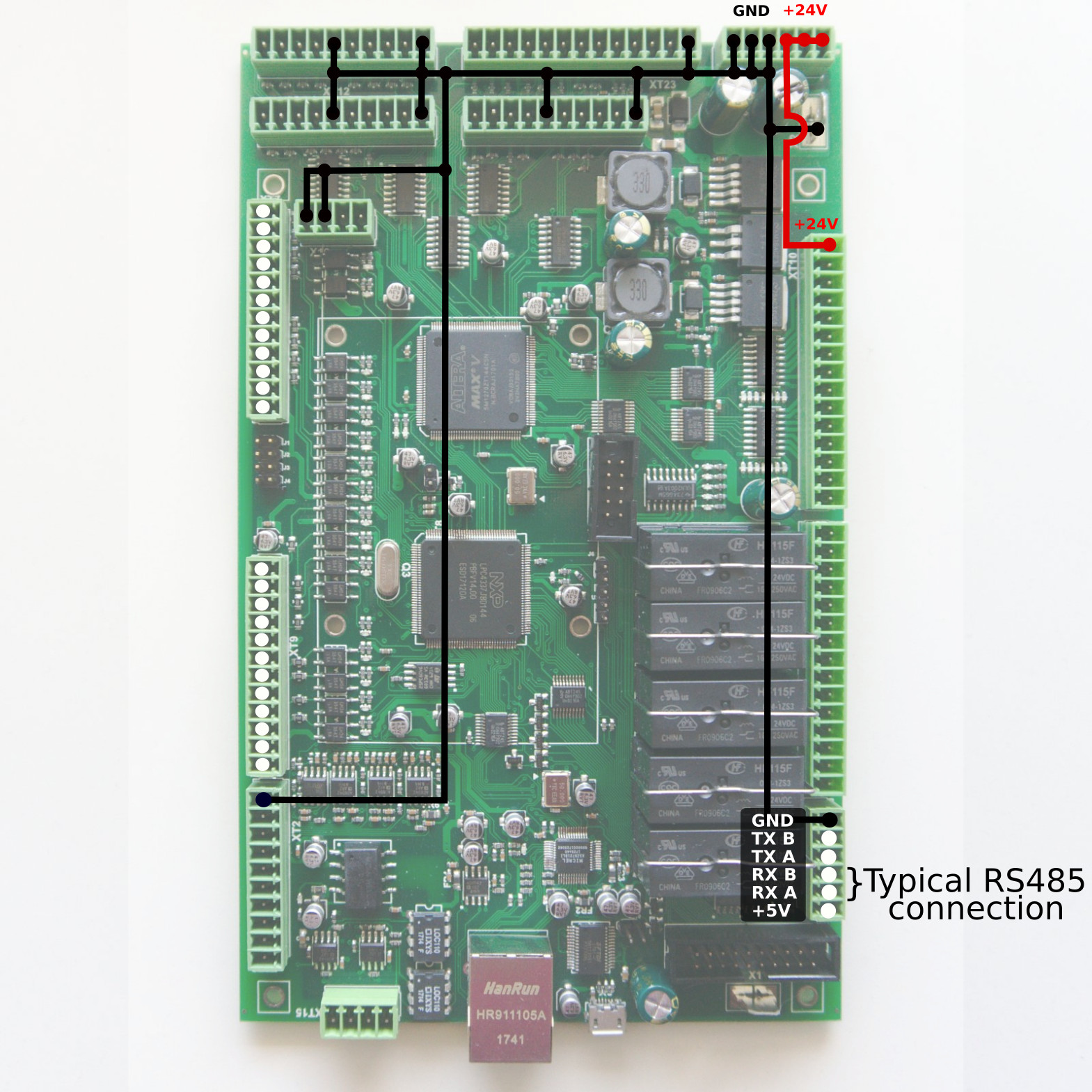

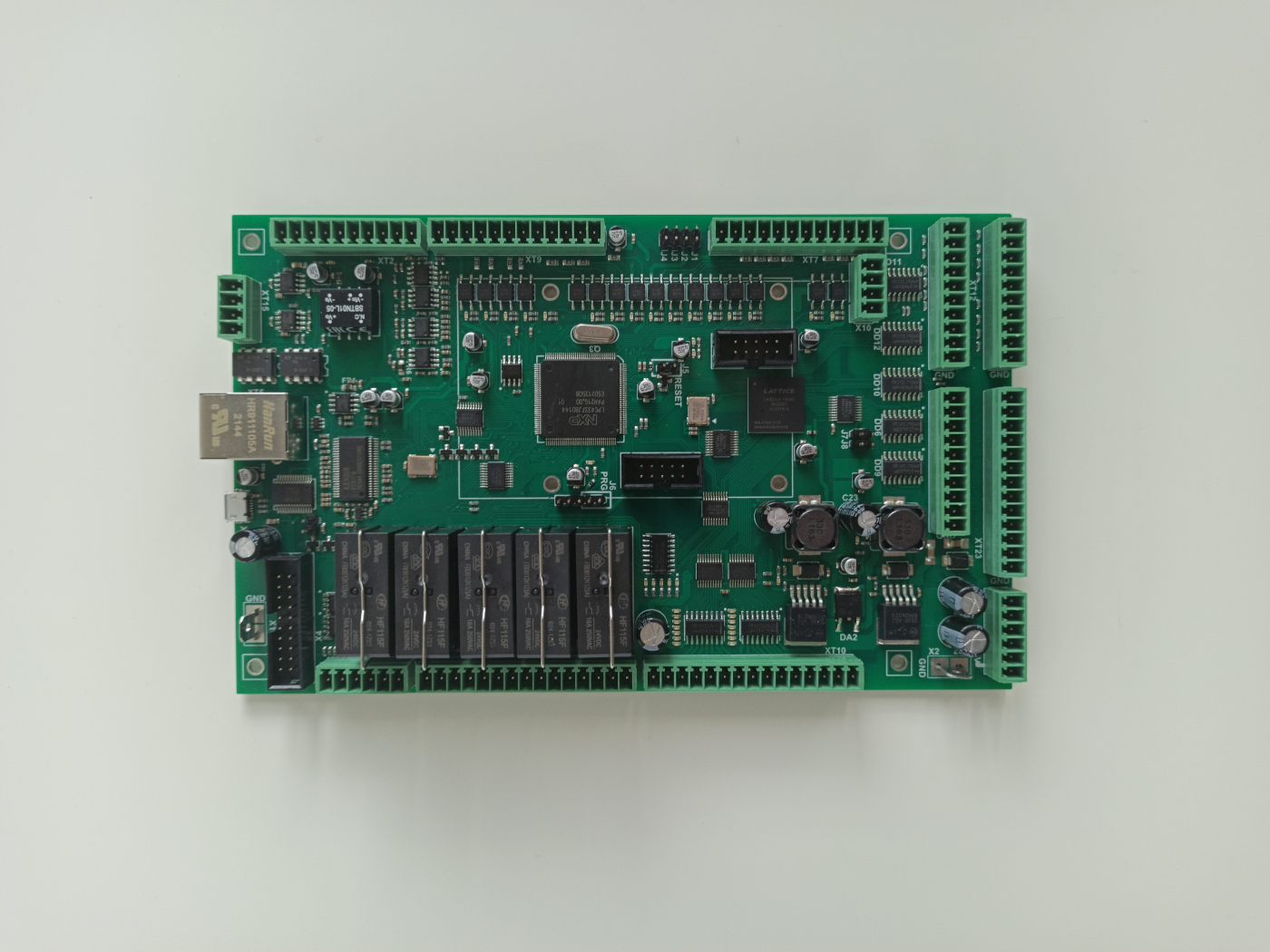

ET7 top view

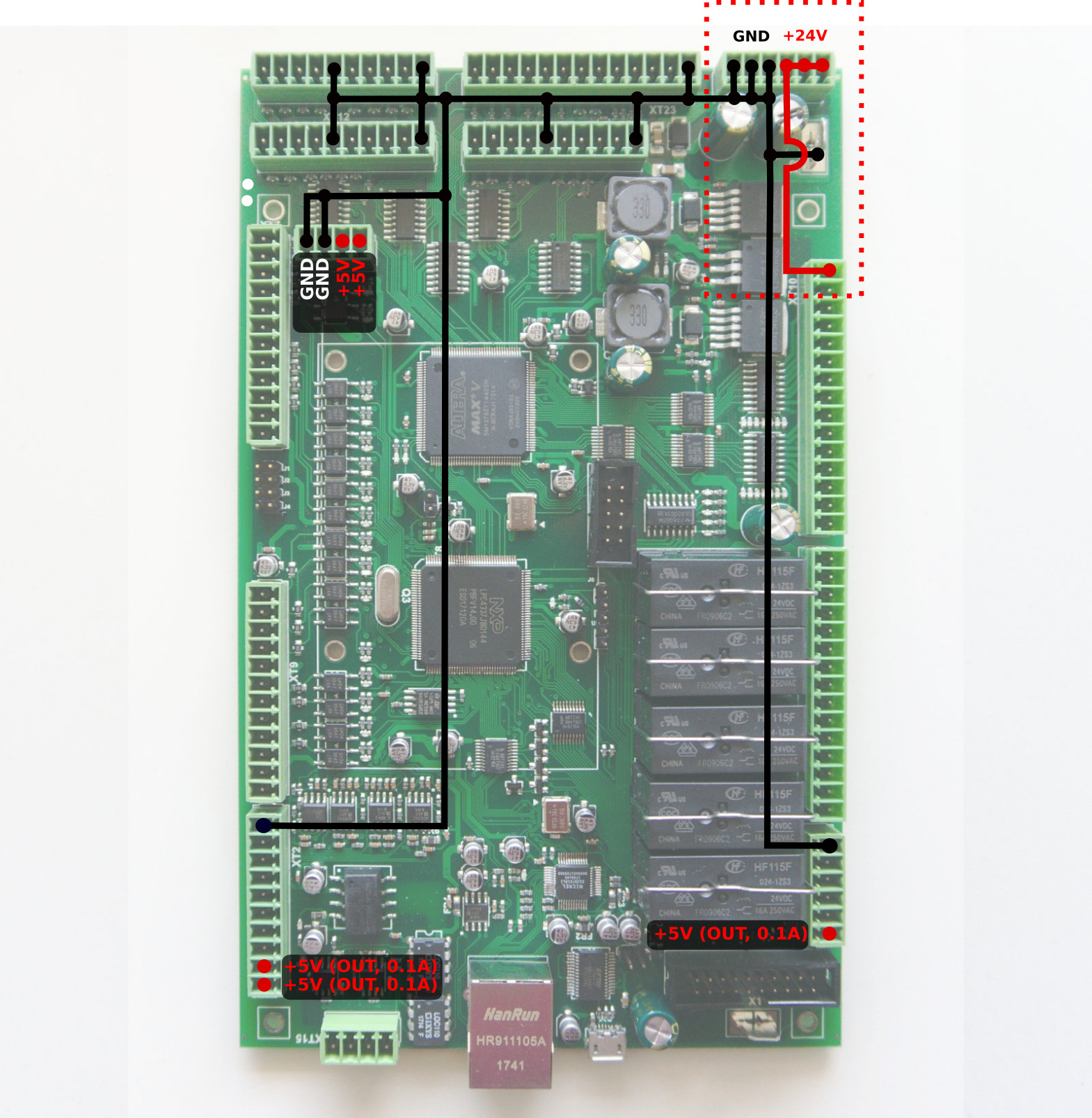

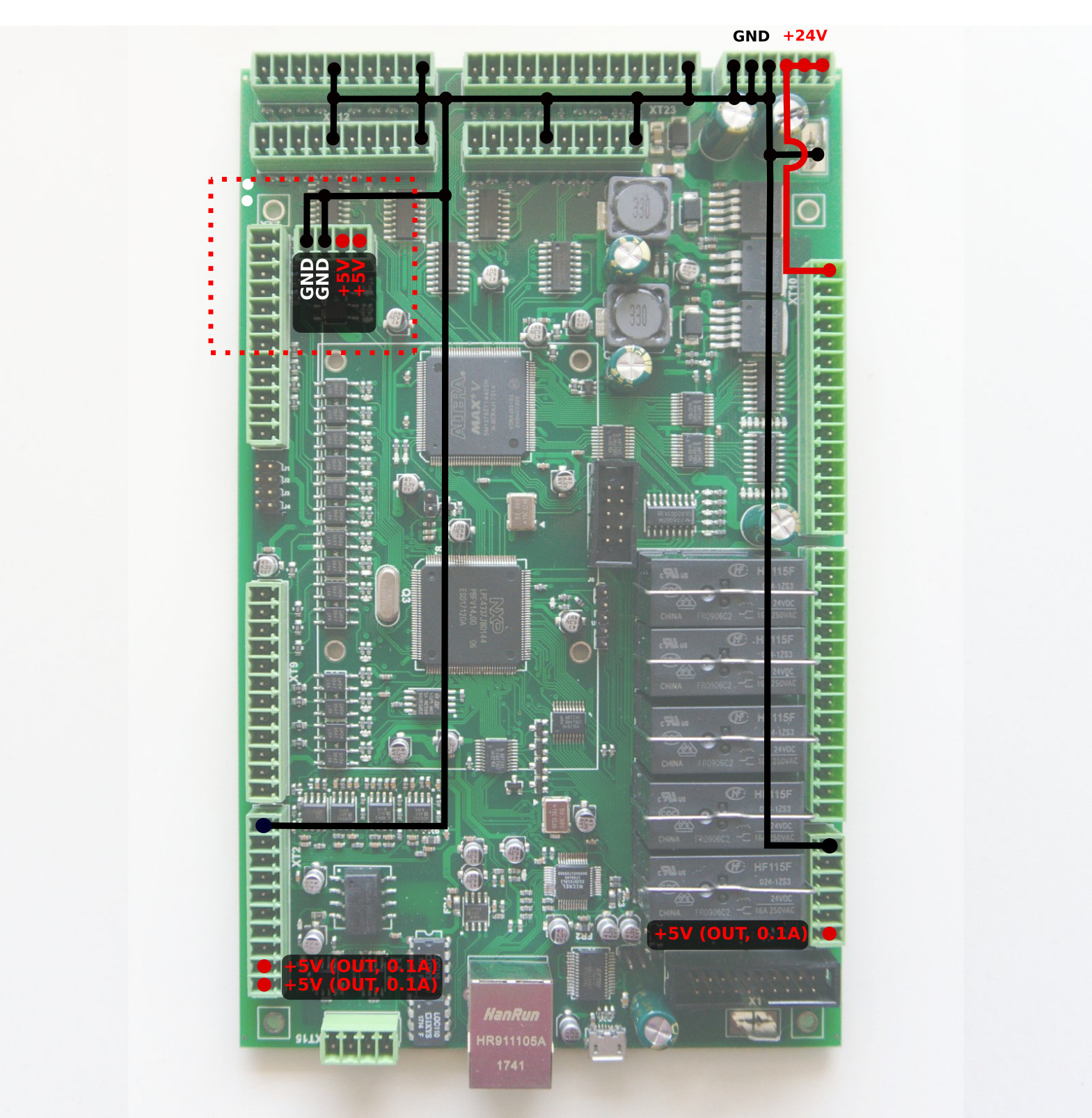

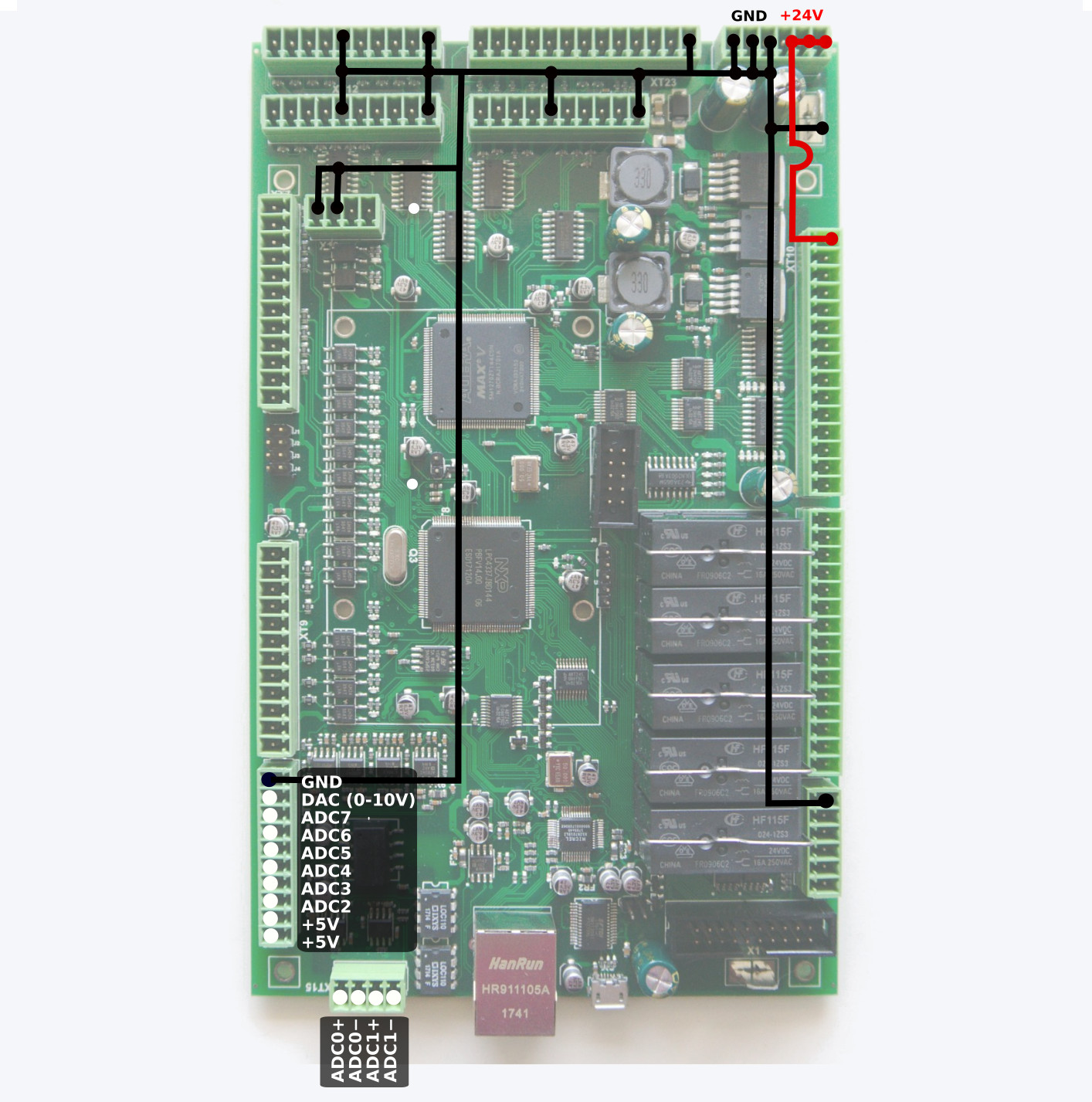

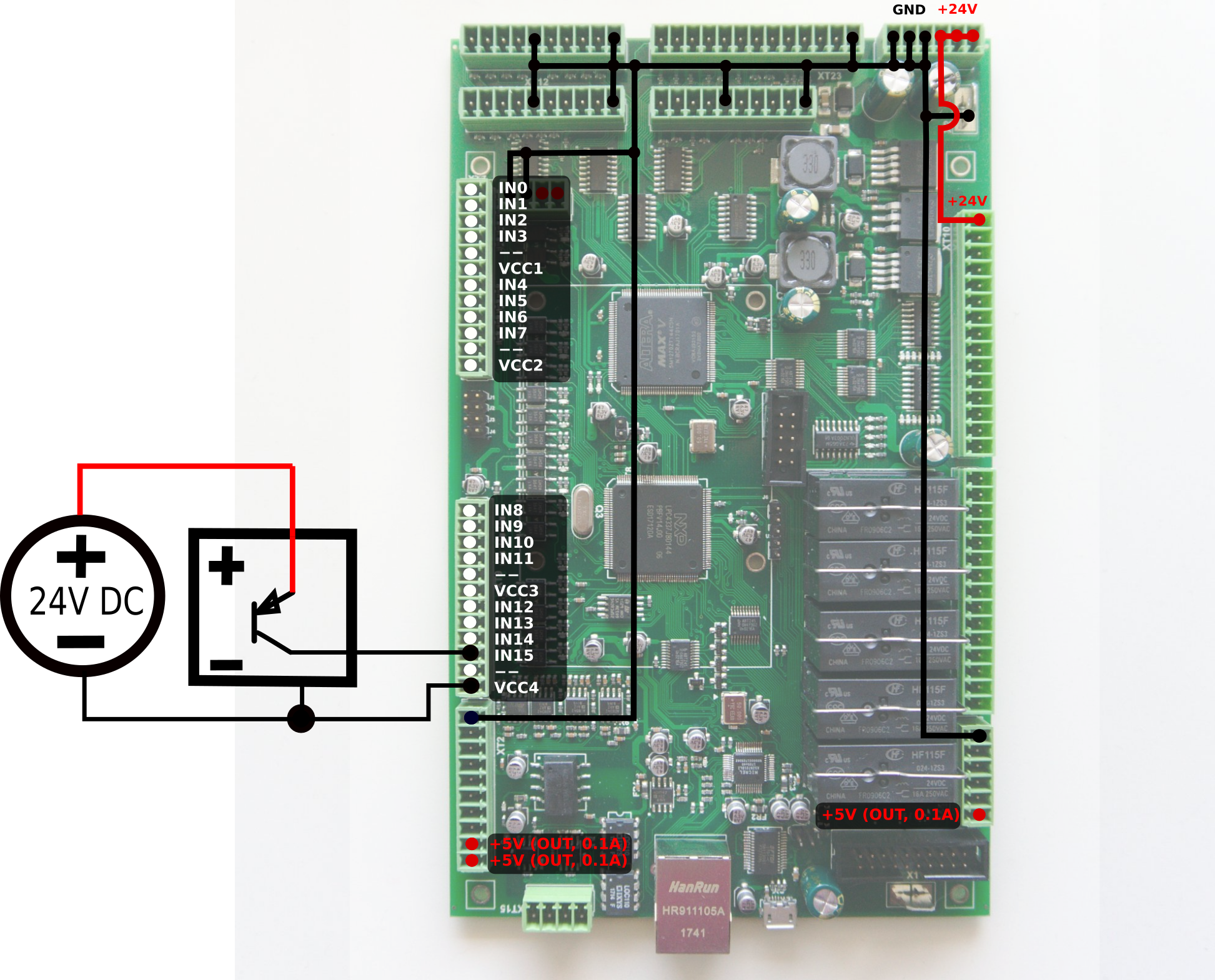

Power supply connection

myCNC-ET7 control board uses 24VDC. The board contains 4 pins for connection +24V (joined internally) and a number of GND pins for convenient connection of external devices. In the diagram below, the top-right 6 pin connector (with 3 pins for GND and 24V each) is used for easy connection of external devices.

A separate 4-pin connector is also available on the board (shown below). This one houses two independent power converters (5V/5V for all new ET7 boards, and 5V/12V for certain older ET7 models) with two GND pins:

For example, this 4-pin power supply connection is often used to power single board computers:

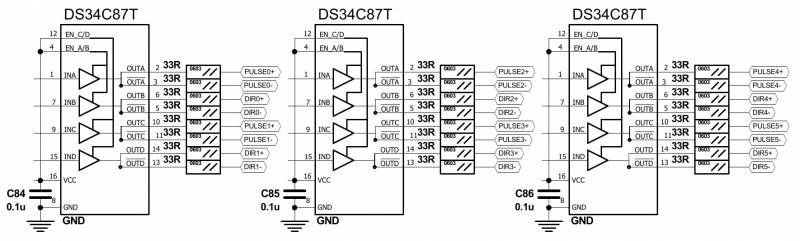

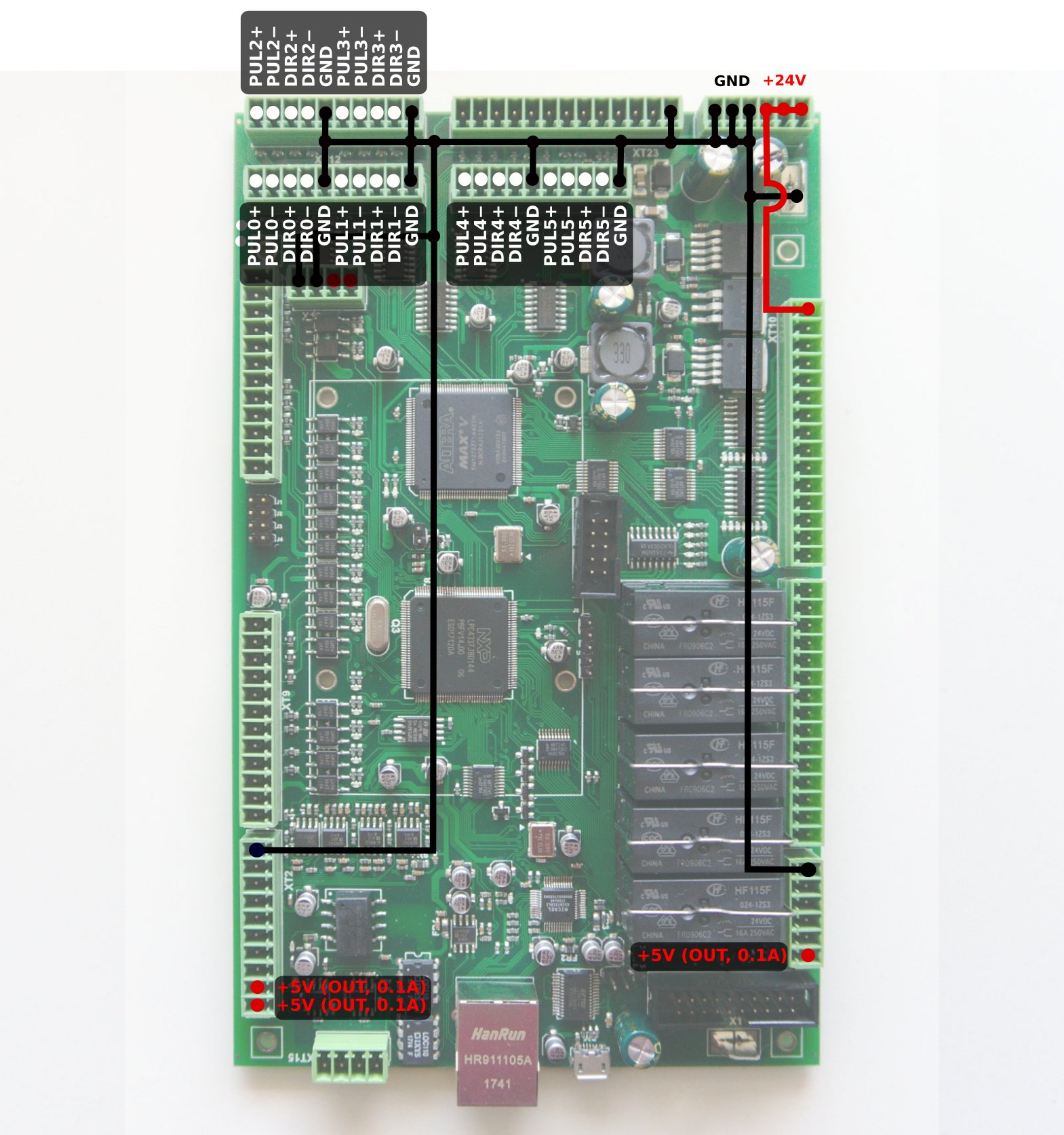

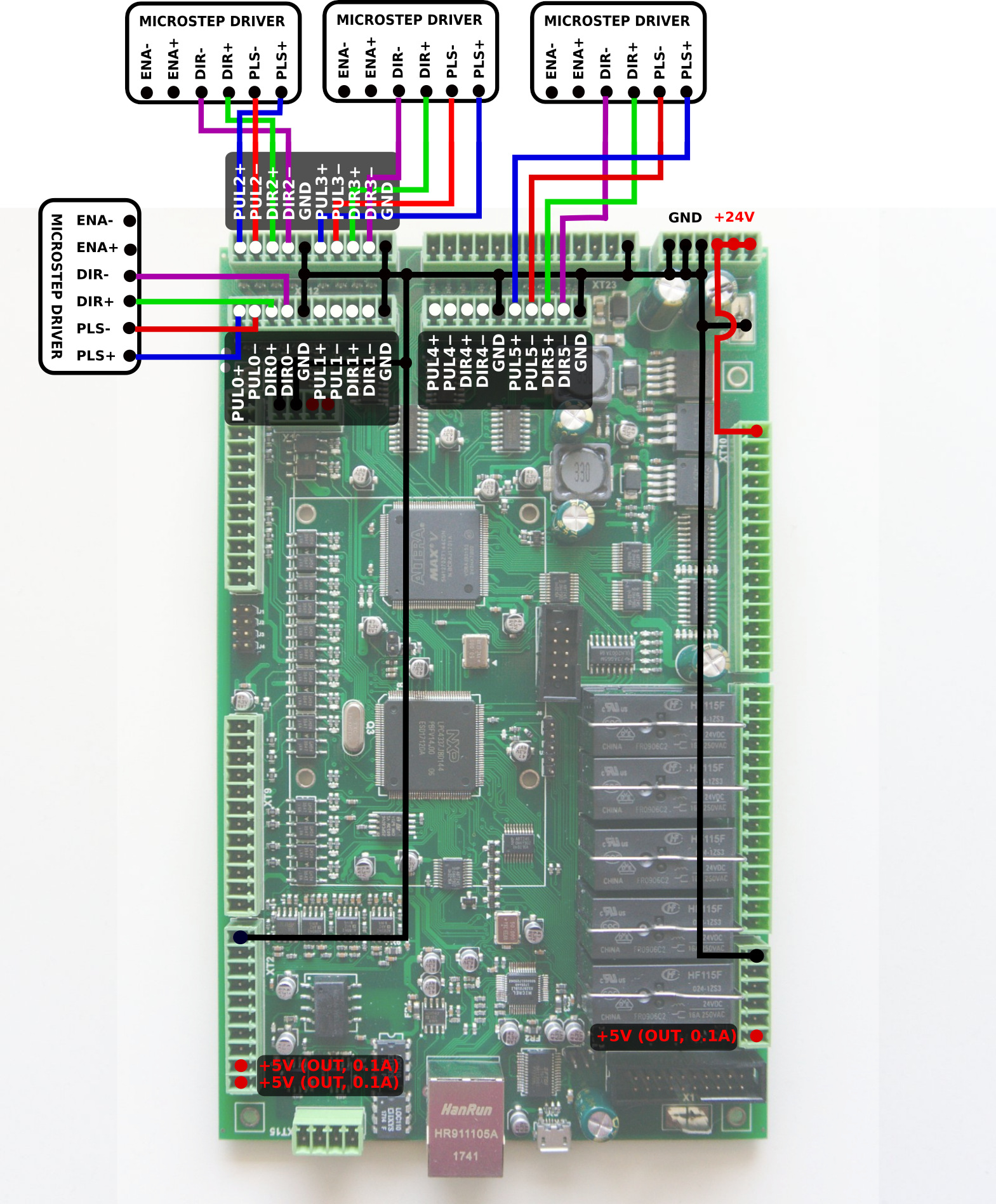

Pulse-Dir outputs

ET7 has 6 channel pulse/dir outputs, 3MHz max pulses frequency.

ET7 pulse dir outputs conform to the RS422 standard and are compatible with most of servo and stepper drivers (line driver with paraphase signals of positive and negative polarity). Internal schematic for pulse-dir is shown on a picture below.

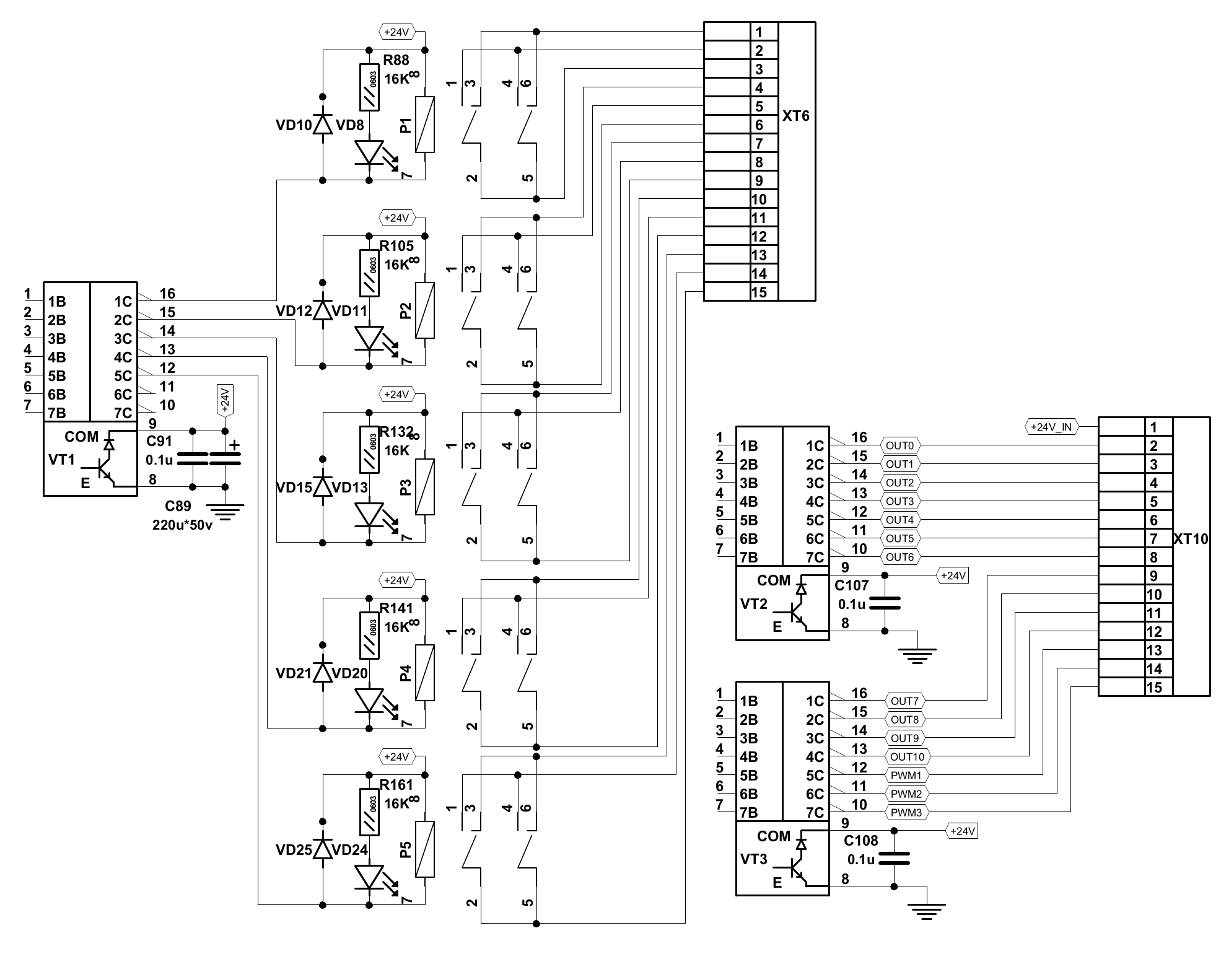

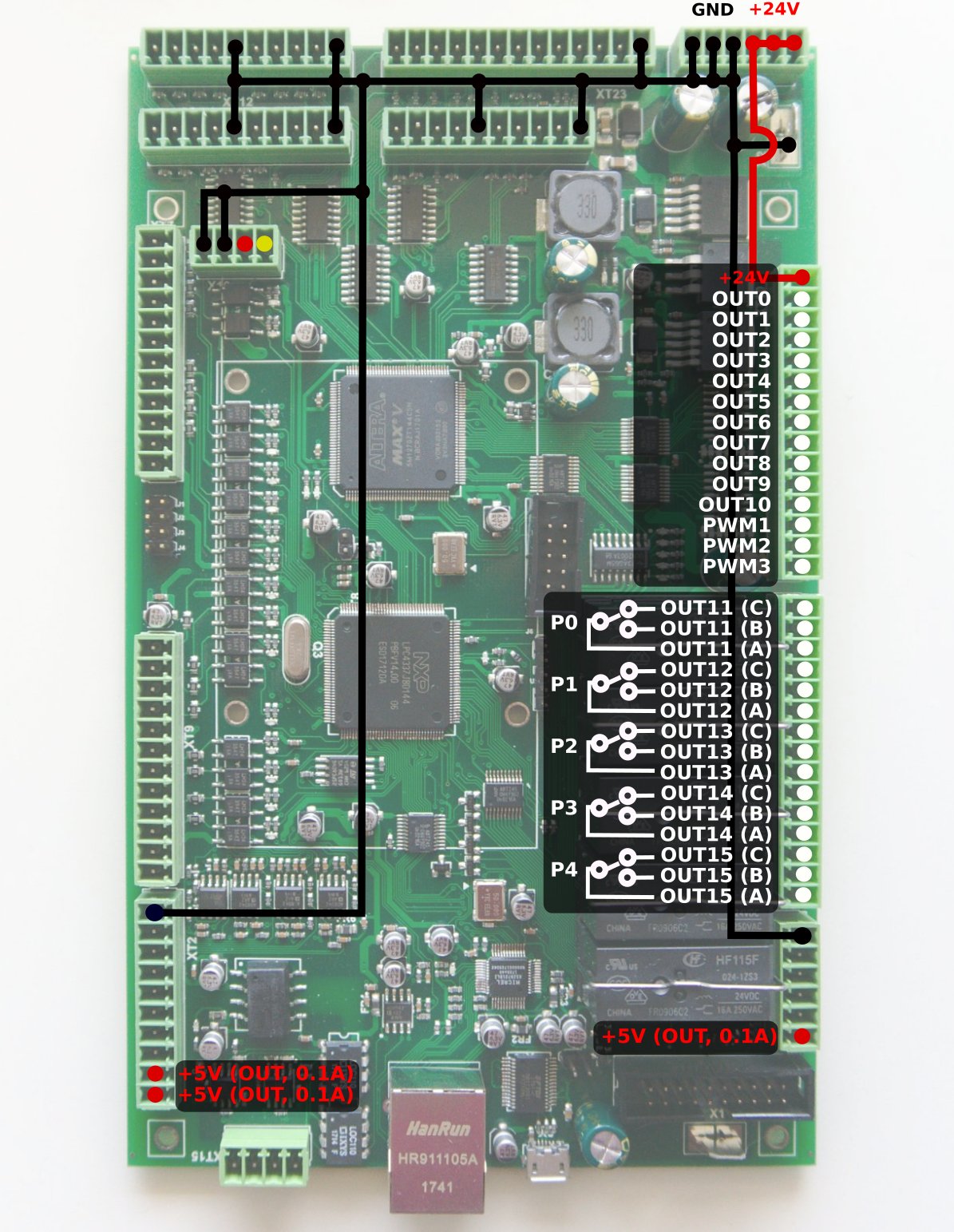

ET7 Output pins

ET7 board contains 19 output pins-

- 5 relay outputs (OUT#11 … OUT#15)

- 11 open collector outputs (OUT#0 … OUT#10)

- 3 PWM outputs (PWM#1, PWM#2, PWM#3)

WARNING: ET7 board rev.1,2 has Output pin names printed on Bottom side of the board. These names are NOT correct and differ from actual output addresses. Please check the table below to find out the actual output address

| SILK print | Actual Output Pin Address |

|---|---|

| OUT0 | OUT0 |

| OUT1 | OUT1 |

| OUT2 | OUT2 |

| OUT3 | OUT3 |

| OUT4 | OUT4 |

| OUT5 | OUT5 |

| OUT6 | OUT6 |

| OUT7 | OUT7 |

| OUT8 | OUT8 |

| OUT9 | OUT9 |

| OUT10 | OUT10 |

| OUT11 | PWM1 |

| OUT12 | PWM2 |

| OUT13 | PWM3 |

| P0A | OUT11 (A) |

| P0B | OUT11 (B) |

| P0C | OUT11 (C) |

| P1A | OUT12 (A) |

| P1B | OUT12 (B) |

| P1C | OUT12 (C) |

| P2A | OUT13 (A) |

| P2B | OUT13 (B) |

| P2C | OUT13 (C) |

| P3A | OUT14 (A) |

| P3B | OUT14 (B) |

| P31 | OUT14 (C) |

| P4A | OUT15 (A) |

| P4B | OUT15 (B) |

| P41 | OUT15(C) |

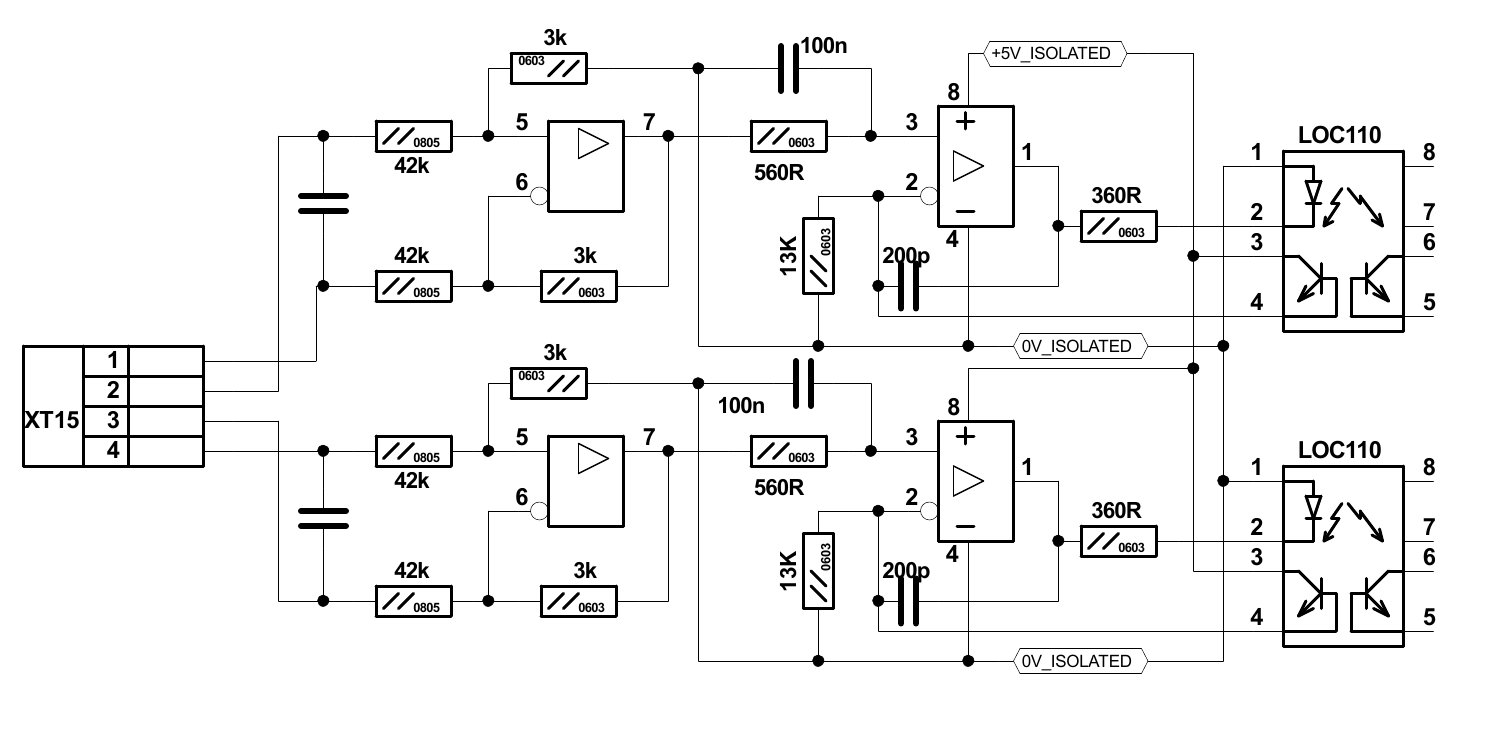

Schematic for ET7 inputs & outputs is shown below

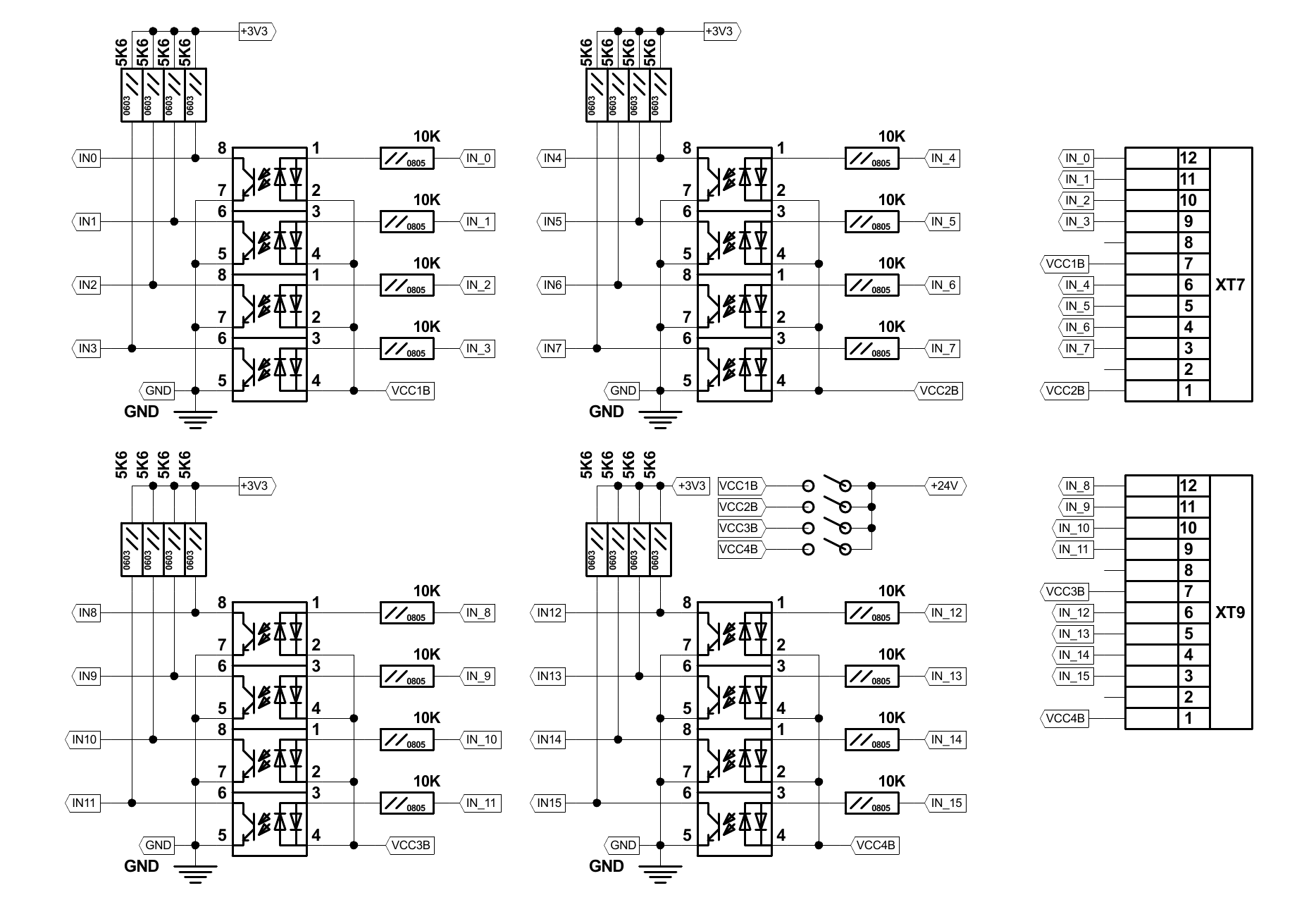

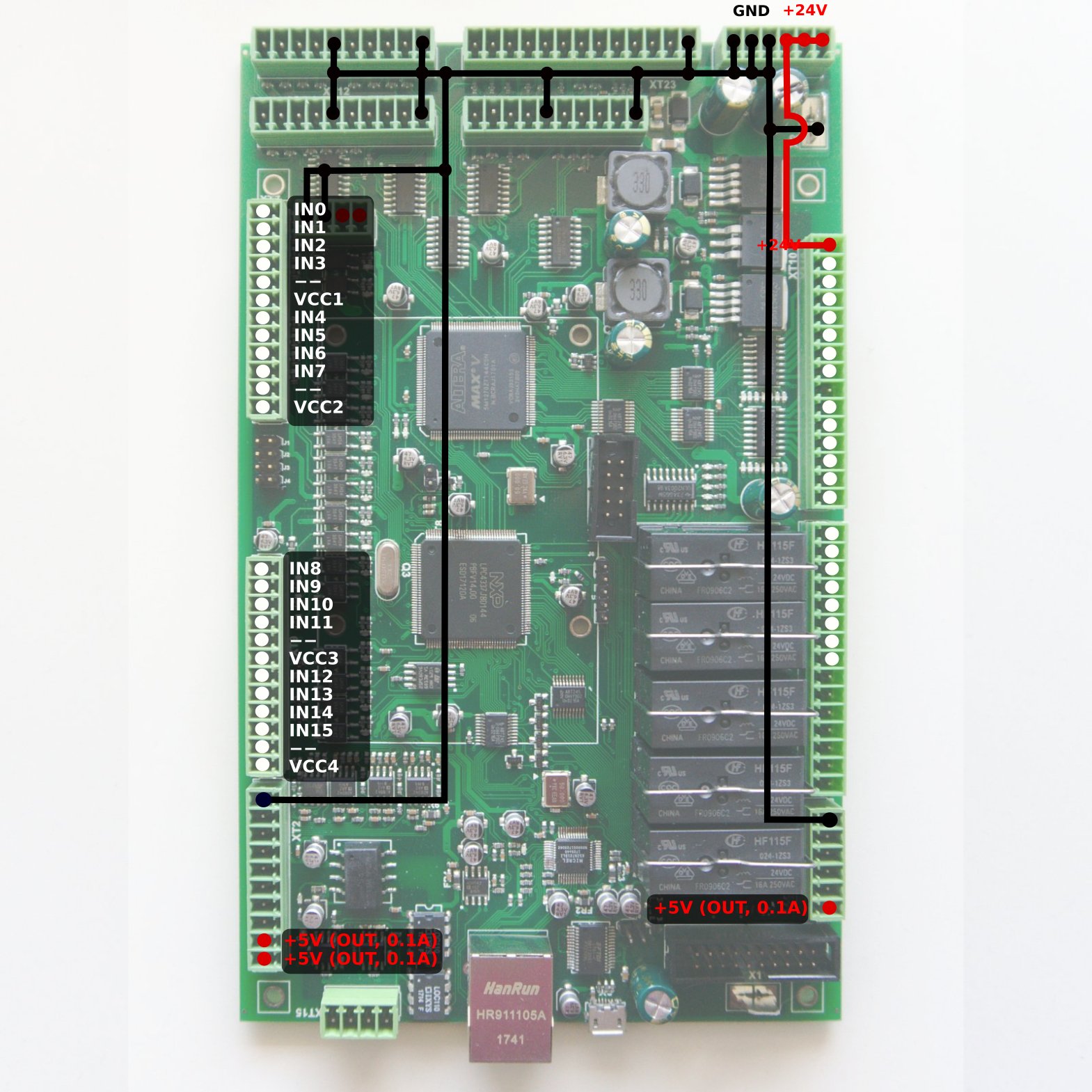

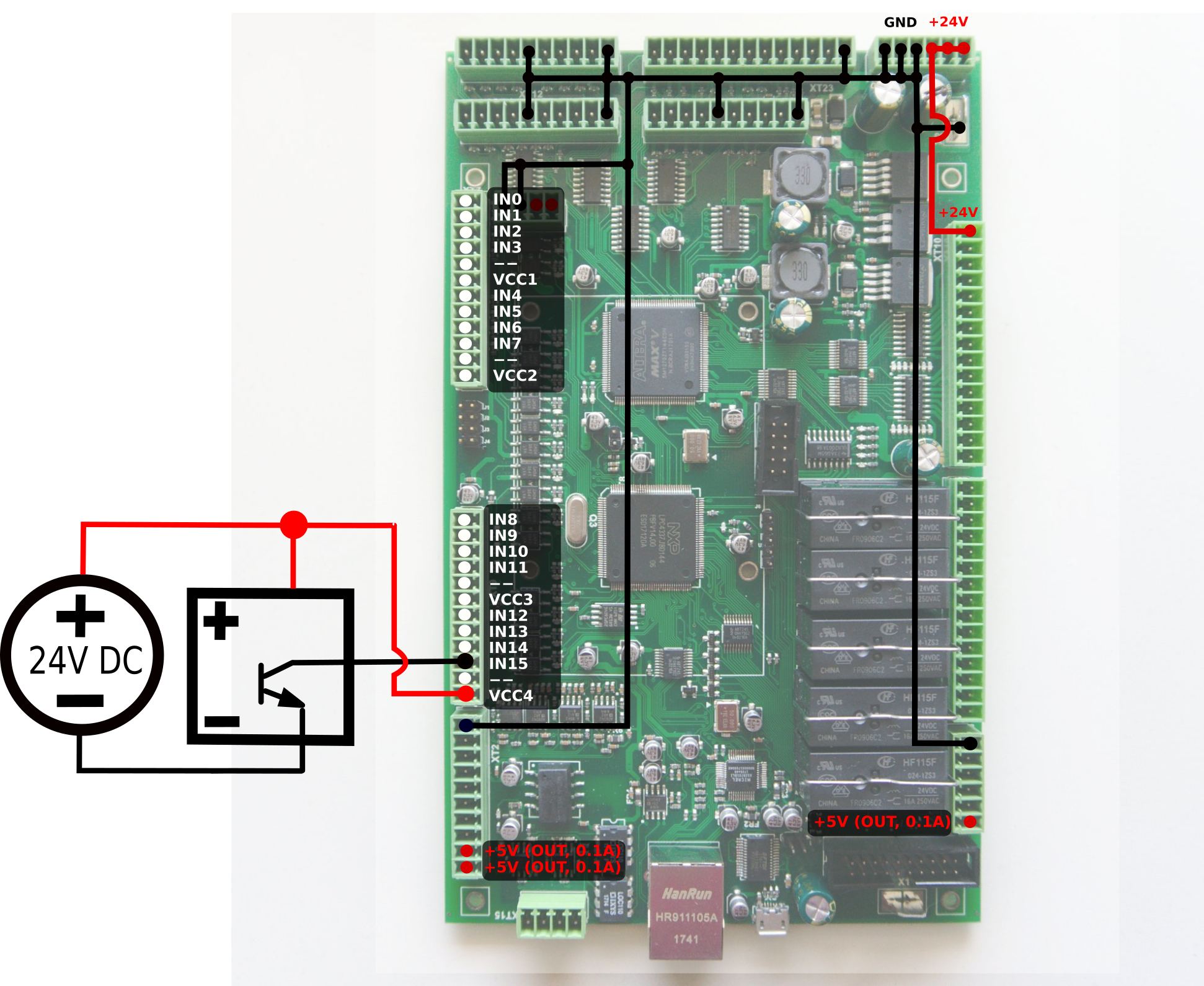

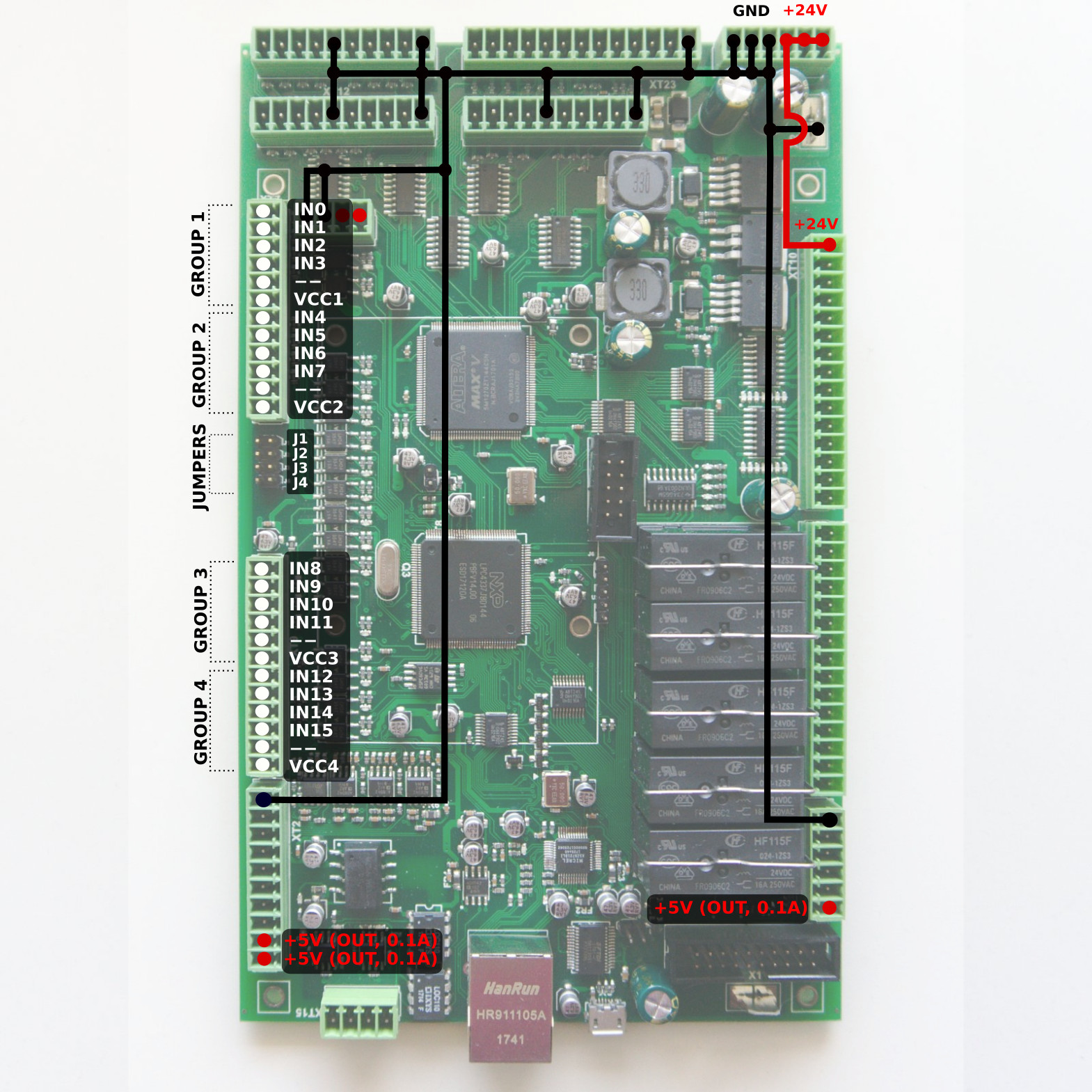

Galvanic isolated inputs

ET7 control board has 16 galvanic isolated binary inputs, 4 groups of 4 inputs each. Each group has separate power supply pins so inputs can be powered from different power sources. Using PNP and NPN sensors simultaneously is possible too.

Galvanic isolated inputs schematic is shown below

Connectors pinout for binary inputs is shown on a picture

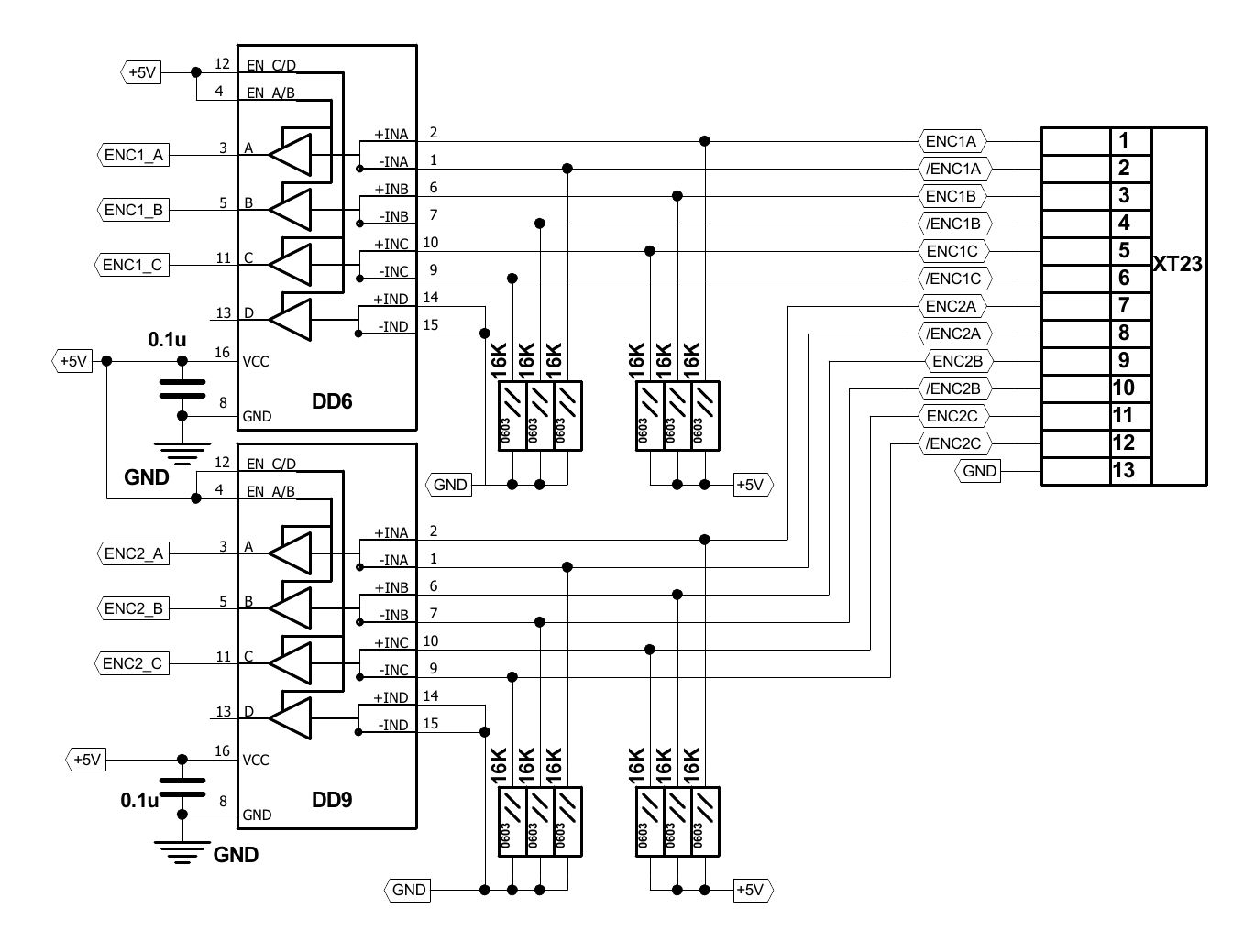

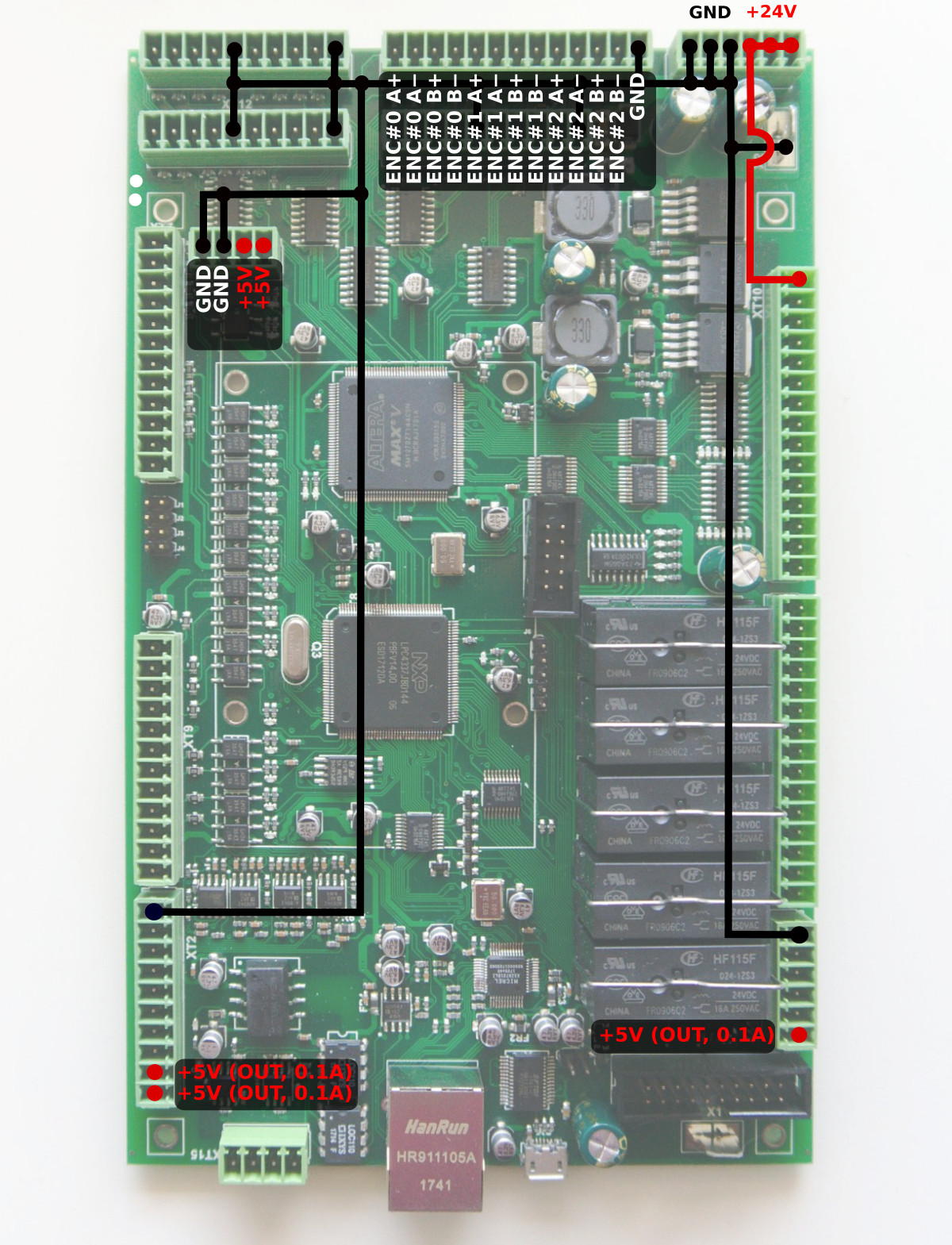

Encoder Inputs

ET7 control board has 3 AB incremental encoder inputs with hardware implemented decoding. Max pulse frequency of encoder pulses is 3MHz. 6 encoder input signals are mapped to General purpose binary input addresses 20…25 and can be used as normal binary inputs. Encoder inputs are line driver differential signal compatible.

Encoder inputs schematic is shown below

Encoder inputs connector pinout is shown in the diagram below:

NOTE: Depending on the board revision version, the +5/+5V power supply in the top left corner may actually be a +5/+12V power supply (on older boards).

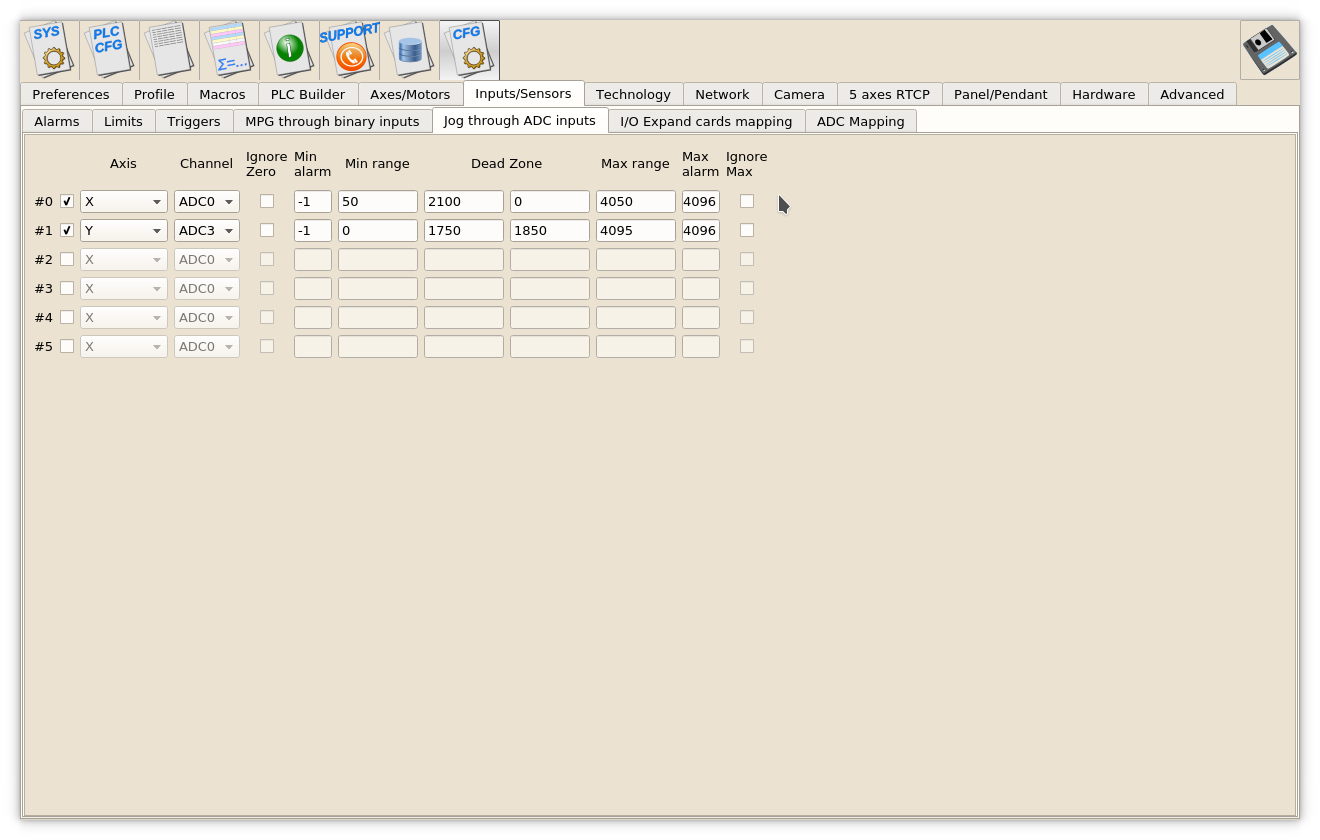

ADC Inputs

myCNC-ET7 controller has 8 ADC inputs.

- 6 ADC inputs 0-5V range

- 2 ADC inputs with galvanic isolation for save and convenient connection of Arc Voltage signal from Power station. There are two isolated ADC inputs - ADC0 and ADC1. Galvanic isolated ADC input ADC0 has the 0…5V (low-voltage) range, while ADC1 is 0..12V, so High Voltage Arc signal CANNOT be connected directly to ADC inputs, voltage divider is NEEDED. Please consult the information below for more info on the ADC0/ADC1 inputs.

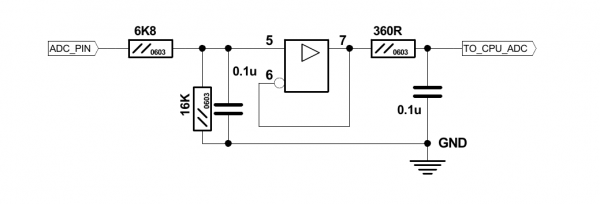

The 0-5 V ADC inputs schematic is shown below:

Isolated ADC inputs schematic is shown below:

Connectors pinout for ADC inputs is shown below

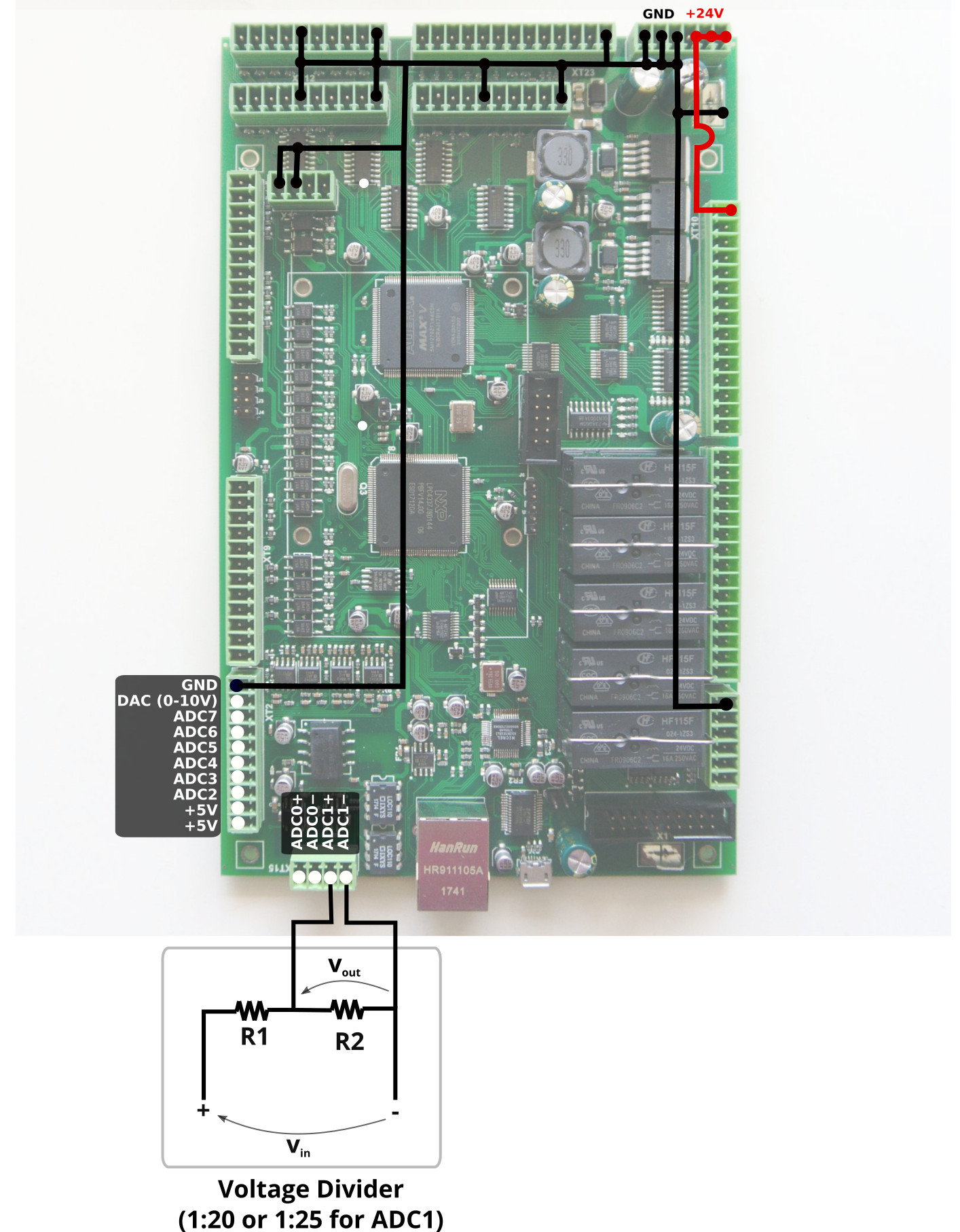

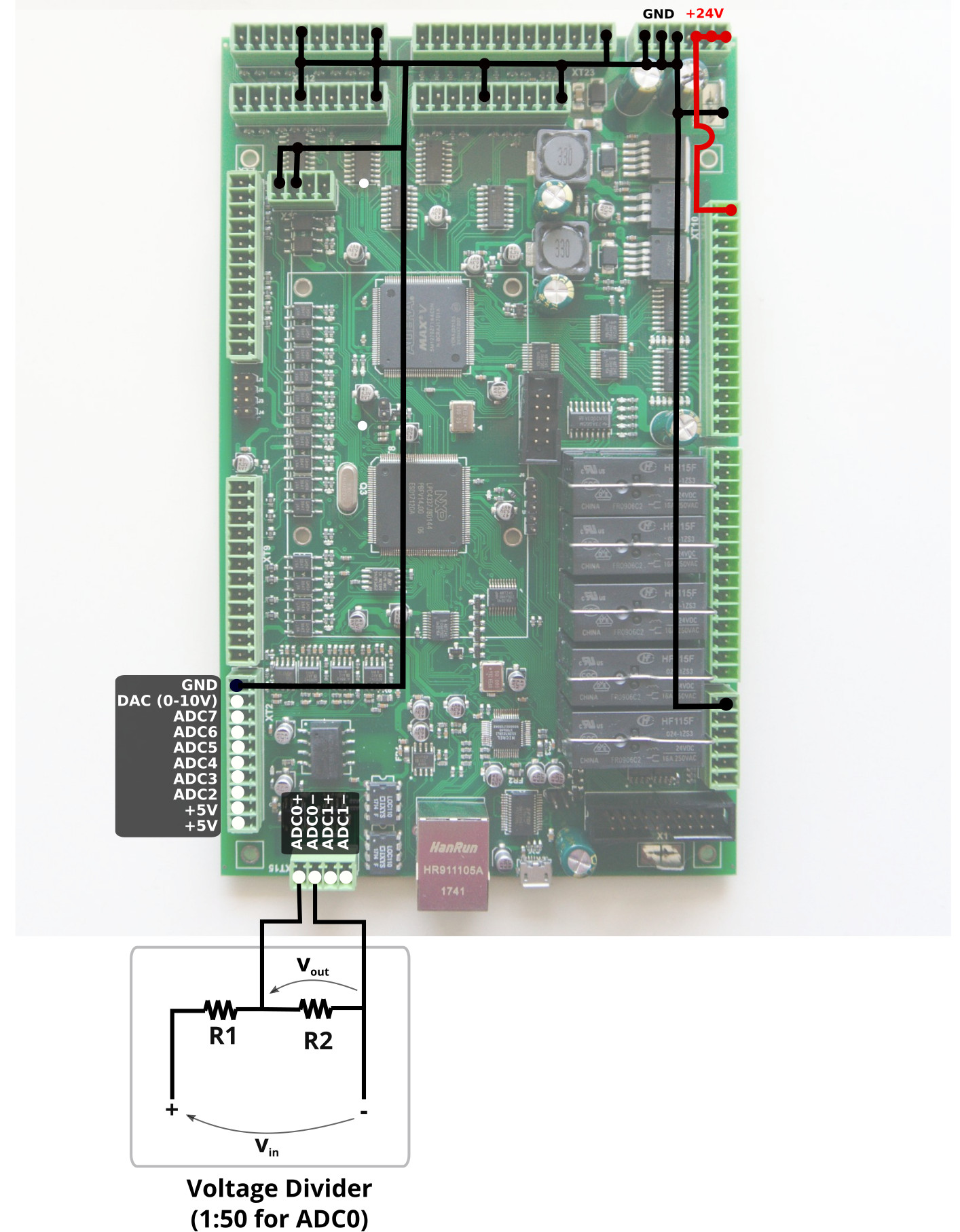

Isolated ADC

WARNING: The names for the ADC inputs printed at the bottom of the board are NOT correct. The silk printing naming for inputs ADC0 and ADC01 are switched. Please consult the above schematics for the ADC0/ADC1 input locations.

A voltage divider can be used for plasma cutting arc. For the 12V ADC ports (ADC1) and voltage in the range of 0-300V, a voltage divider with a 1:25 ratio may be used (a 1:20 ratio can be used for voltages up to 240V).

For example, using the standard Vout=Vin*(R2/[R1+R2]) formula, we can see that for a 1:20 ratio, the resistors must be selected in such a way as to achieve a R1=19*R2 ratio.

Similarly, for ADC0 (isolated, with a range of 0-5V), a voltage divider with a 1:50 ratio is required (for voltages up to 300V). On older (prior to 2020) models of the myCNC-ET7 controller, the range on the ADC0 inputs was similarly 0-12V, however in the interest of user convenience the two ADC ports can now be used for a variety of power sources and voltage dividers.

Non-isolated ADC

Non-isolated ADC inputs (ADC2-ADC7) have a 0…5V Range. Connector with non-isolated ADC inputs also has the GND and +5V DC output pins for convenient potentiometer connection. Picture below shows an example for potentiometer connected to ADC2 input.

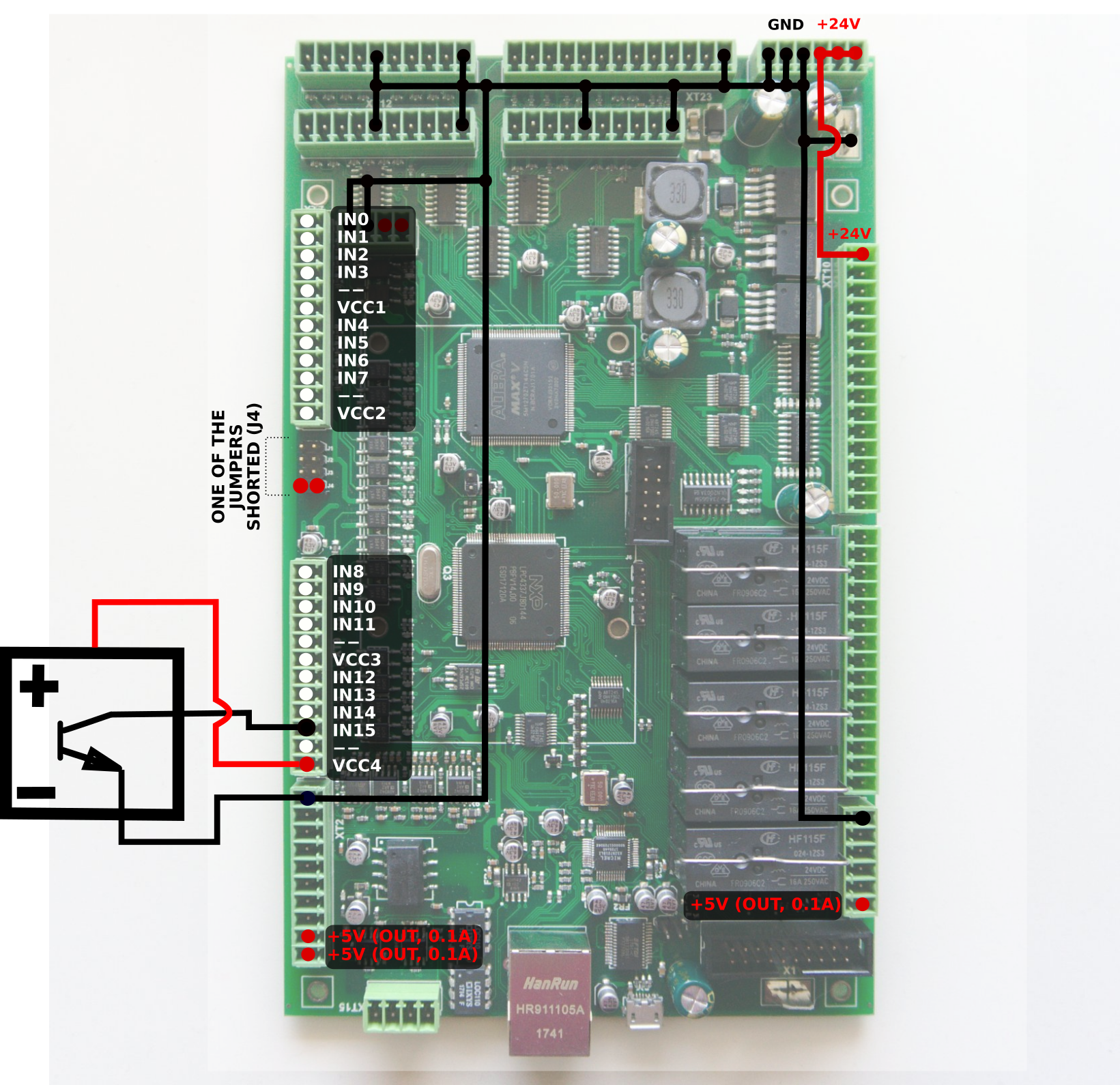

Jumpers J1, J2, J3 and J4

In order for the board connections to function without an external power supply, the connections can be wired as to draw power from the +24V power supply of the board itself. In order to simplify the setup required for this procedure, jumpers 1 through 4 are put in place, as shown in the diagram below:

Each jumper corresponds to its respective IN group number (for example, J4 for Group 4). In this way, in a configuration without an external power supply, the correct jumper for the group can be closed to supply power from the internal +24V. The switch should also short the wire to GNC (0V) in order for the circuit to be closed.

WARNING: If an external power supply is used, respective jumpers for the group should be OPEN

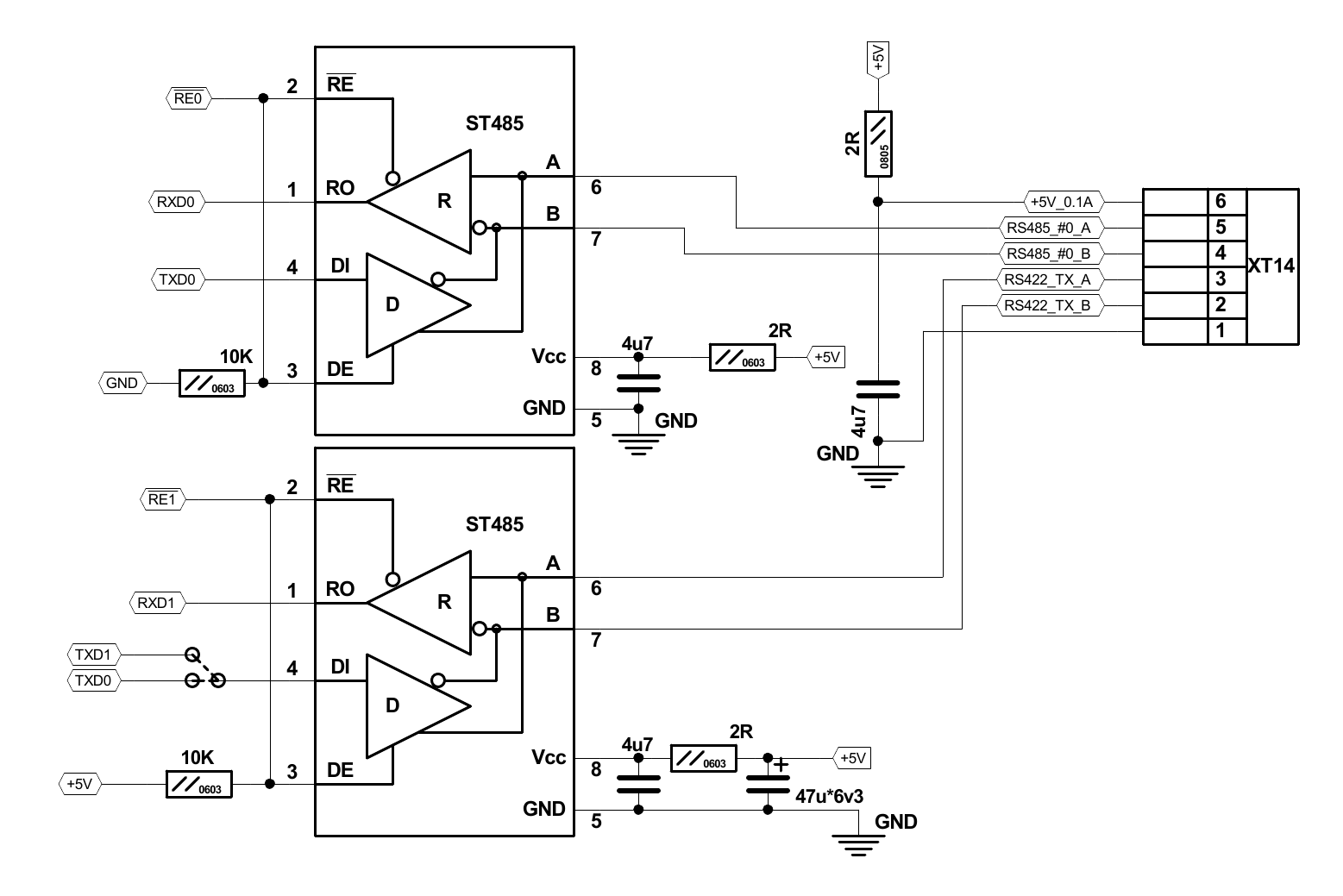

RS422/RS485 Bus

The myCNC-ET7 control board has a RS422/RS485 bus connector. Modbus ASCII/RTU and Hypertherm Serial communication interfaces are implemented in the myCNC-ET7 control board.

RS485 bus is enabled by default.

To enable RS422 interface you need to

- close jumper J(#)

- setup RS422 interface in the control software.

Please contact our support team if you need to use a RS422 bus.

A RS422/RS485 schematic is shown below

RS422 connector pinout shown below. NOTE: While all of the RX/TX ports (RX A, RX B, TX A, TX B) are used for the RS422 connection (such as a Hypertherm machine), only RX A and RX B are utilized in an RS485 configuration.

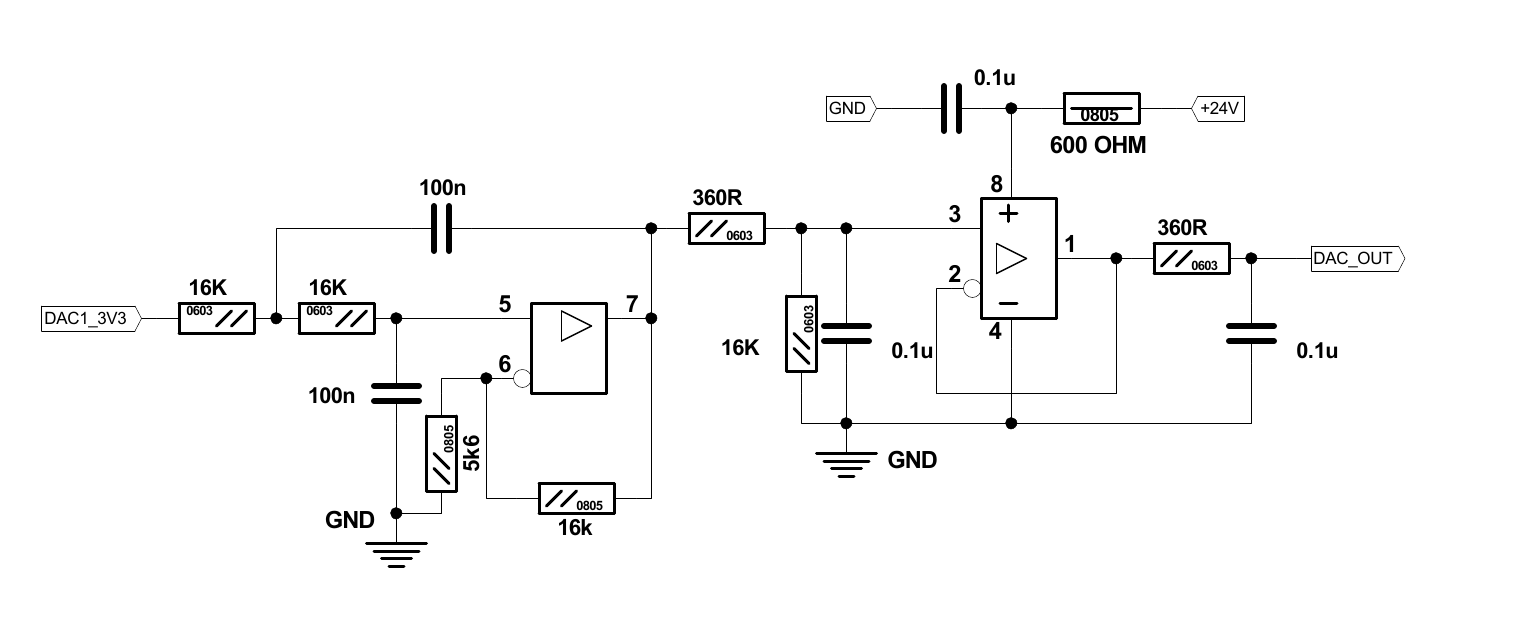

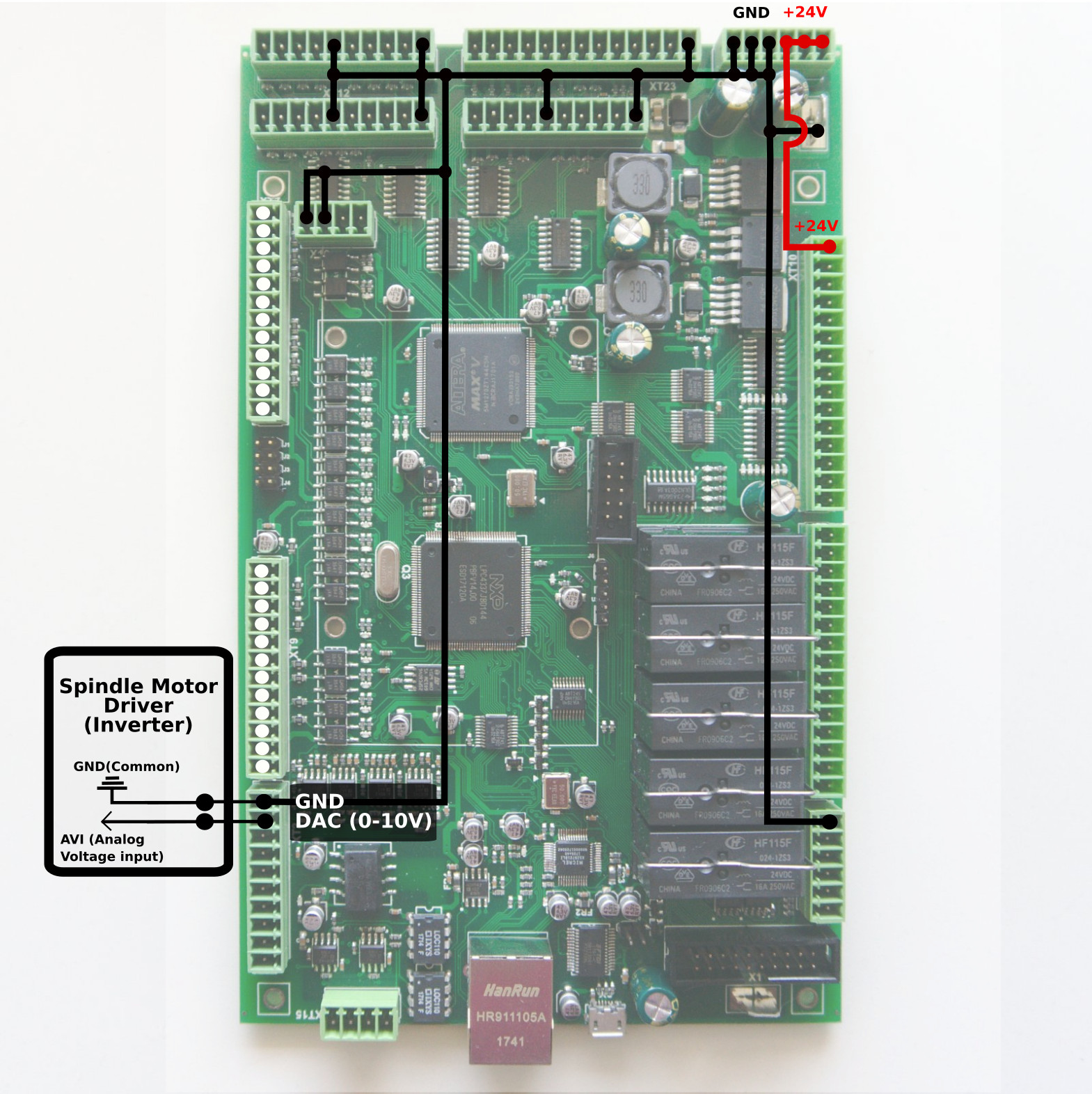

DAC output

The myCNC-ET7 control board has a DAC output for spindle speed control. DAC output range is 1..12V Actual Max DAC voltage (ie 10V, 5V, 6V) can be set up in the myCNC control software.

Connection Examples

Stepper driver connection (4 axes)

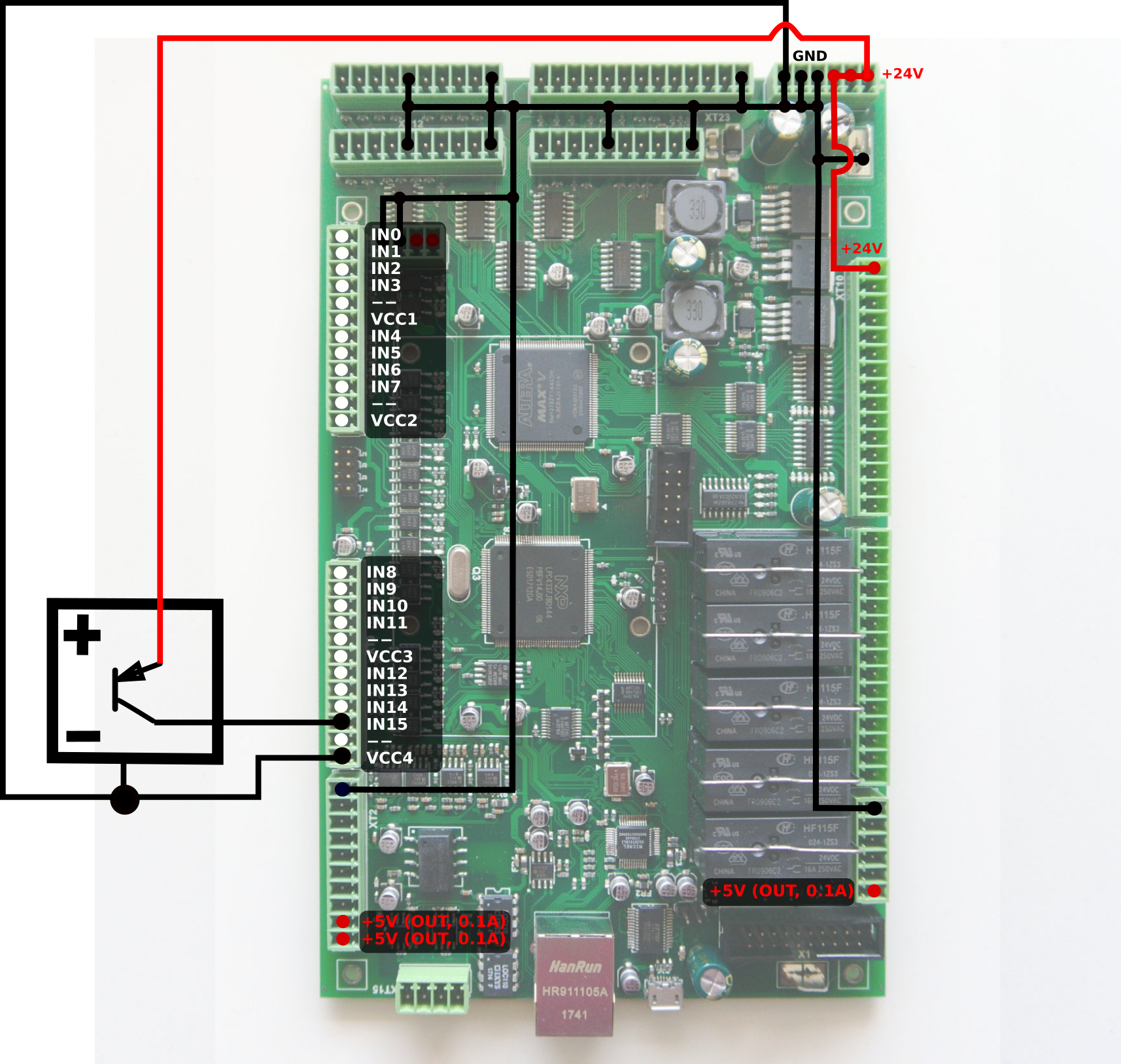

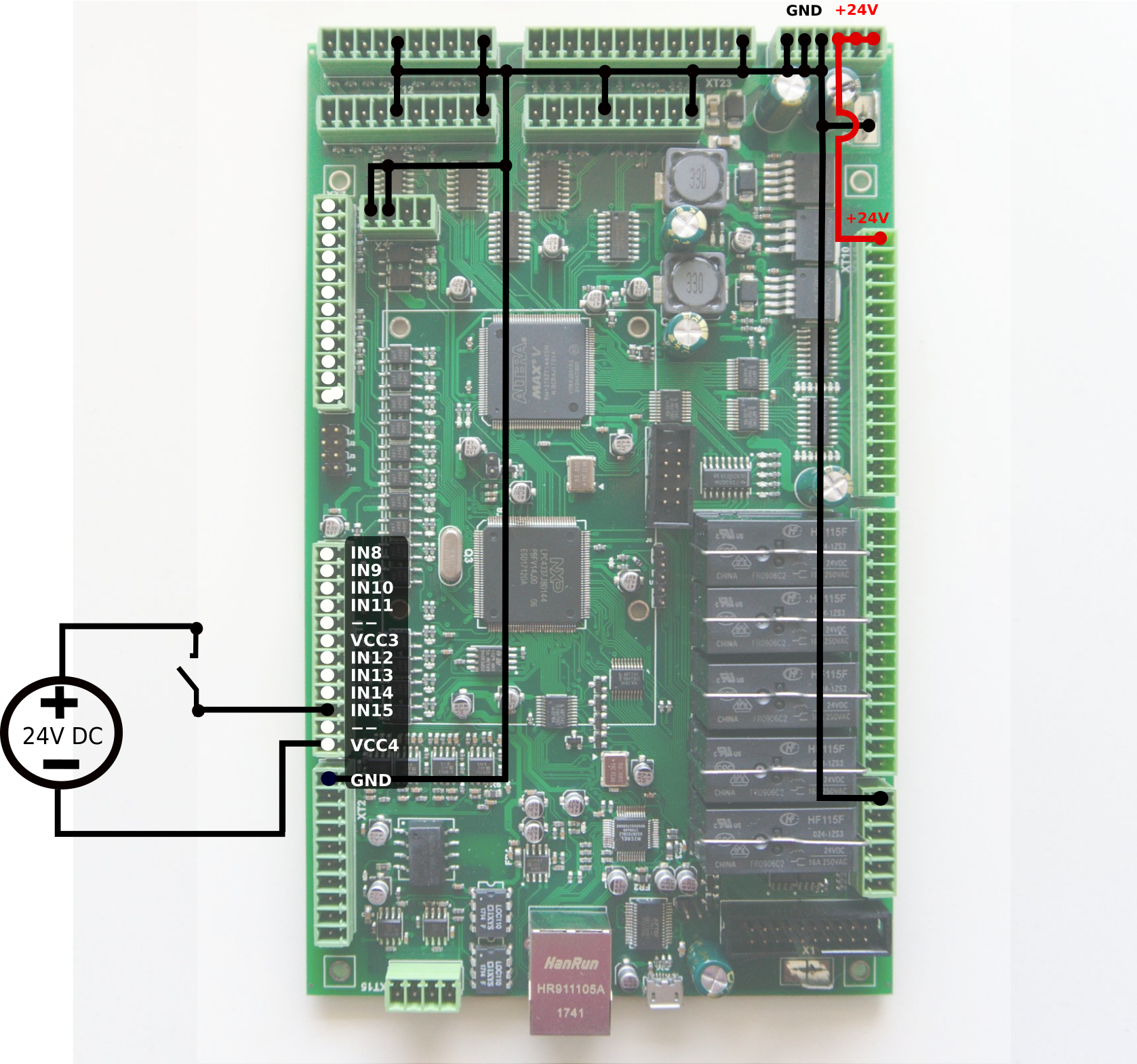

3-wire NPN sensor connection example (external power supply)

3-wire PNP sensor connection example (external power supply)

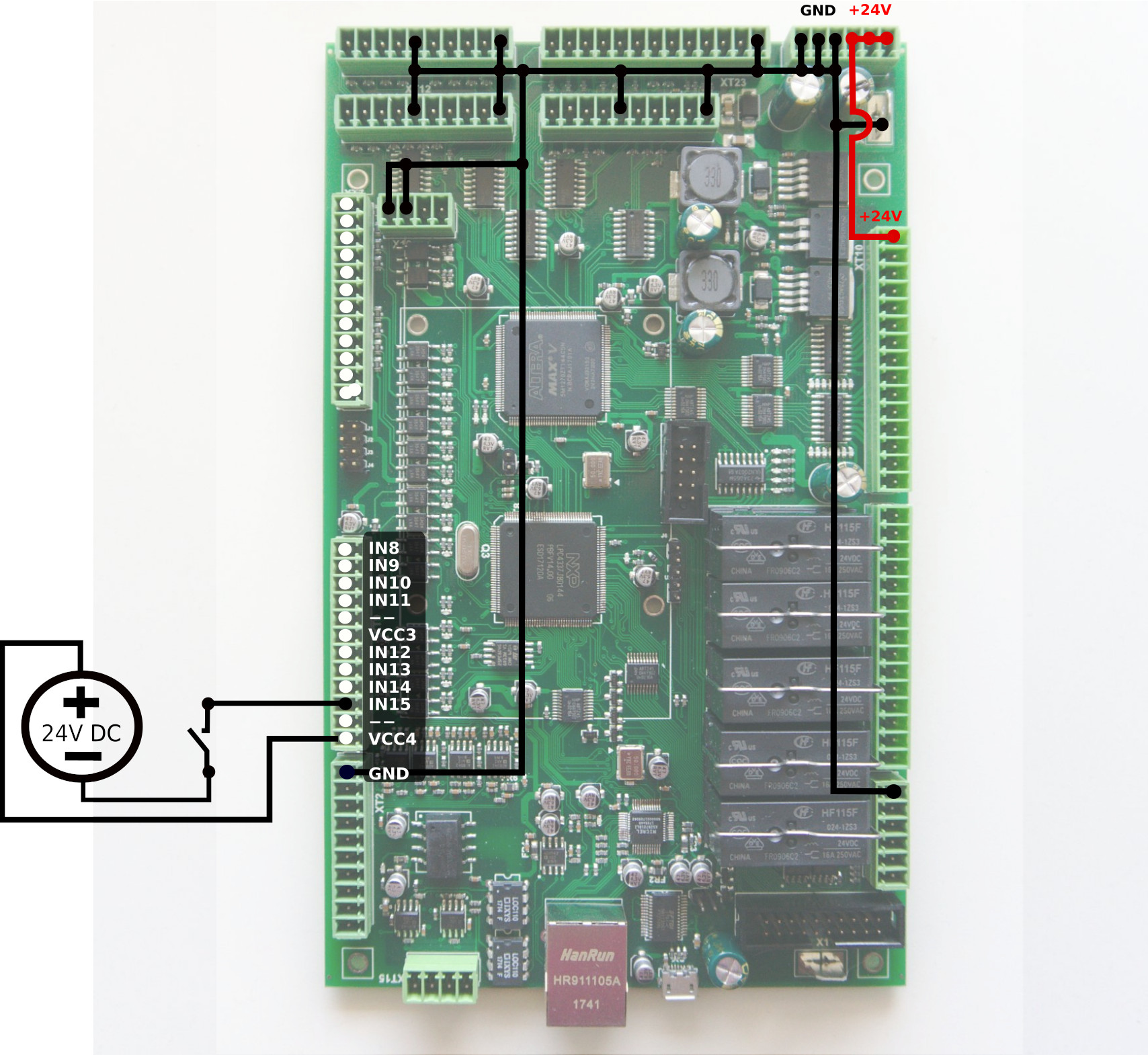

3-wire NPN sensor connection example (internal power supply)

3-wire PNP sensor connection example (internal power supply)

Internal power supply. All of jumpers J1,J2,J3,J4 are open.

As the sensor requires a 24V power supply, it is necessary to connect it to the 24V port, not the 5V.

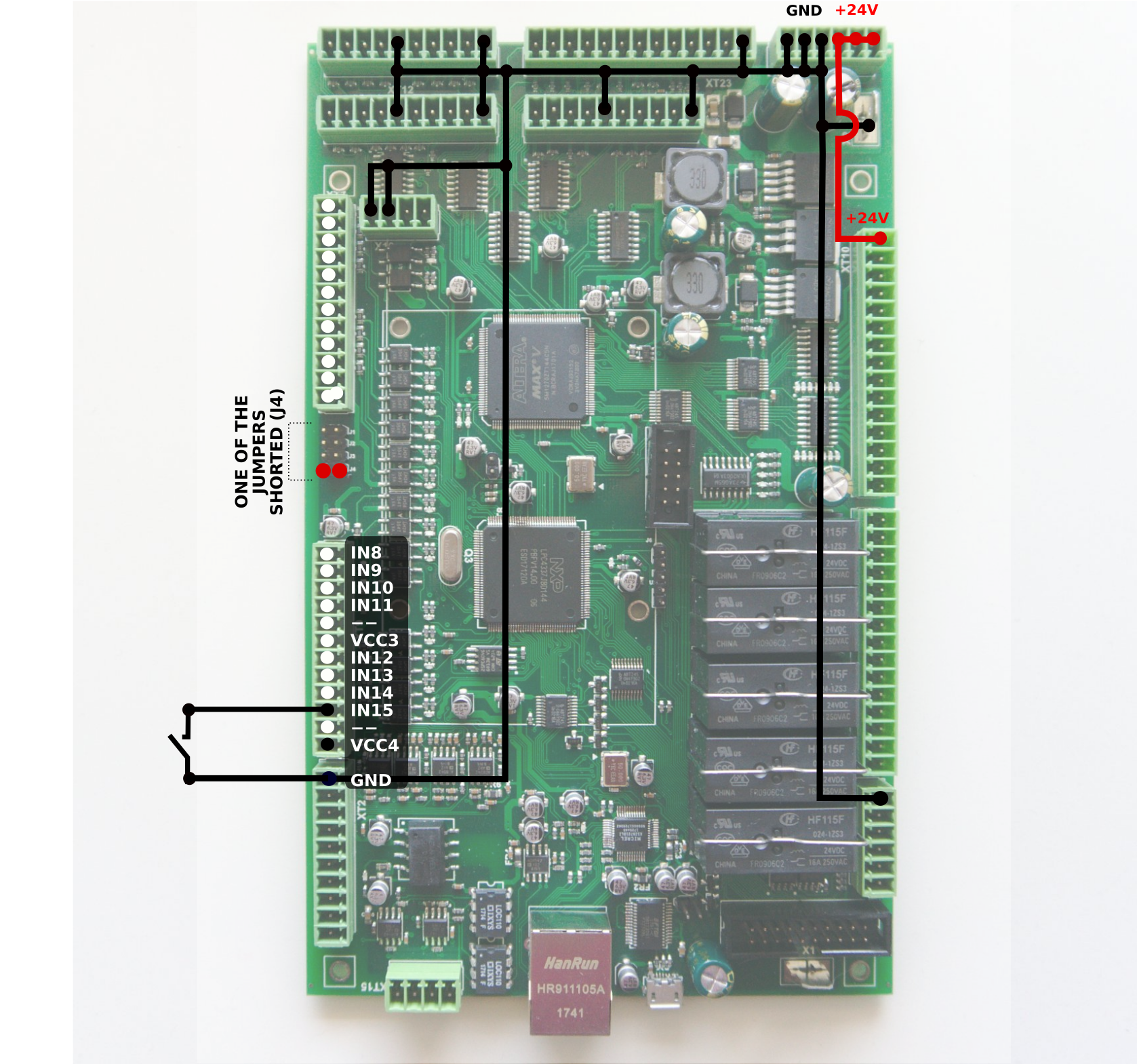

Switch connection example (internal power supply)

Jumper for selected group (one of J1,J2,J3,J4) is closed.

Common wire for 4 optocouple units is connected to internal +24V if Jumper is closed. Switch should short another optocouple input to GND (0V) to activate input pin.

J(#) - in this case, J4 - should be closed to connect optocouple pin to +24V. Switch should also short the wire to GNC(0V).

Switch connection example (external power supply)

Spindle Speed control over DAC (0-10V) output

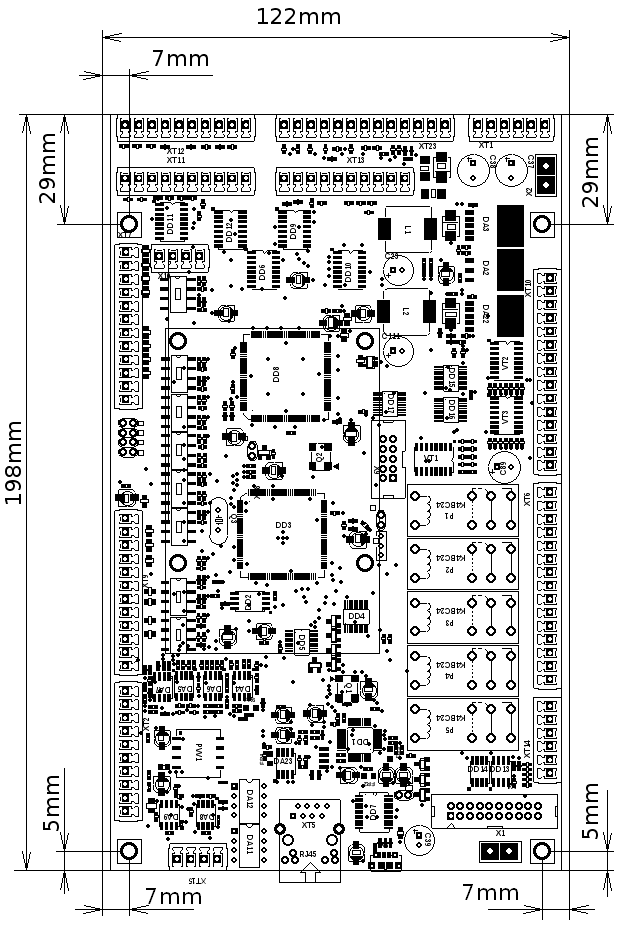

Board dimension

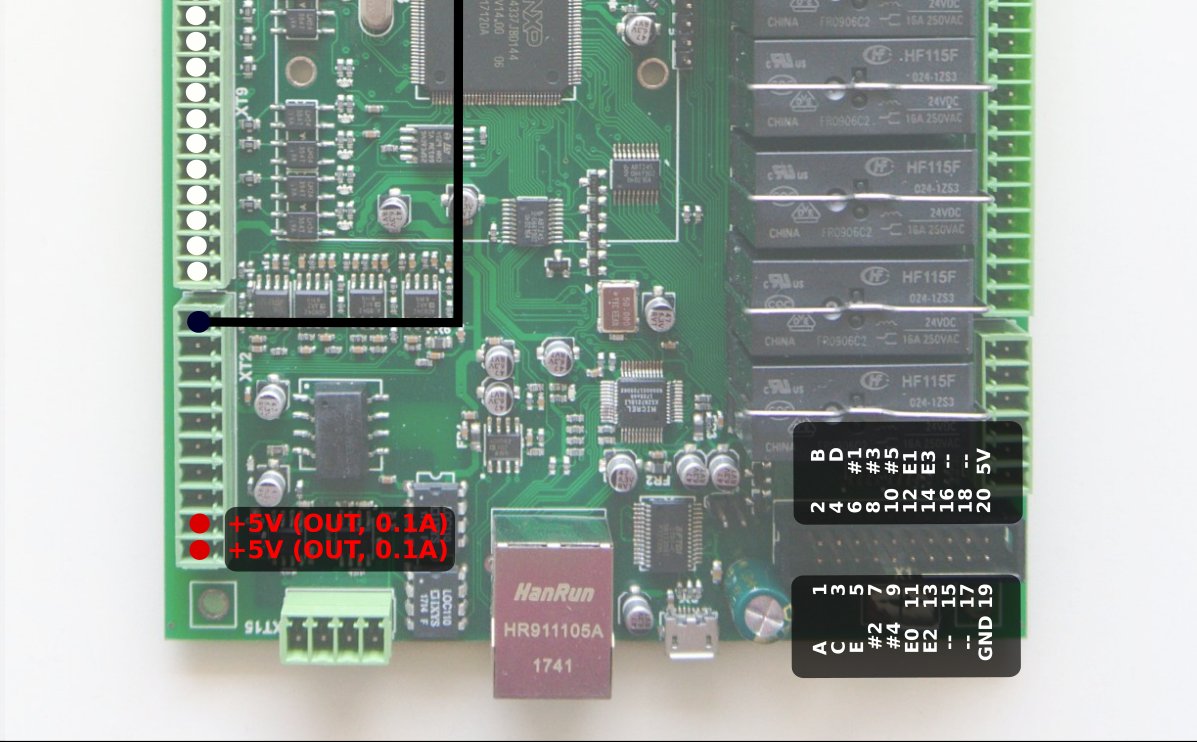

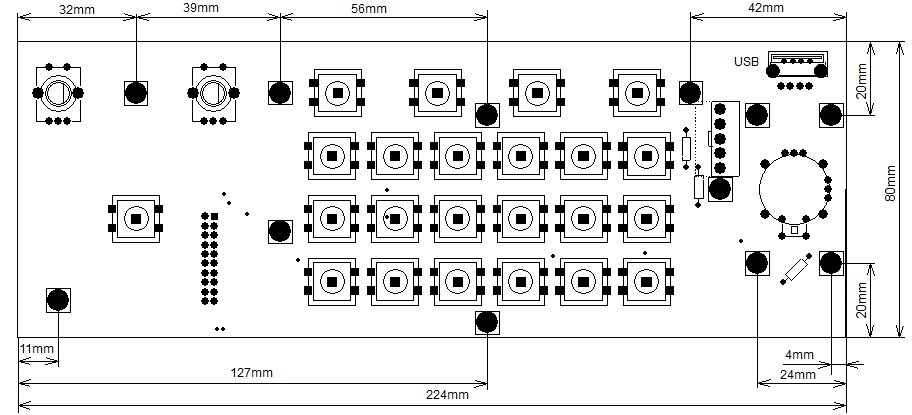

ET7 keypad board

We have a simple keypad board that can be used with the ET7 controller. Keypad board is connected to an ET7 controller through a `20 wires flat cable. Keypad contains 23 keys, 2x rotary encoders and double-axes simple resistive joystick.

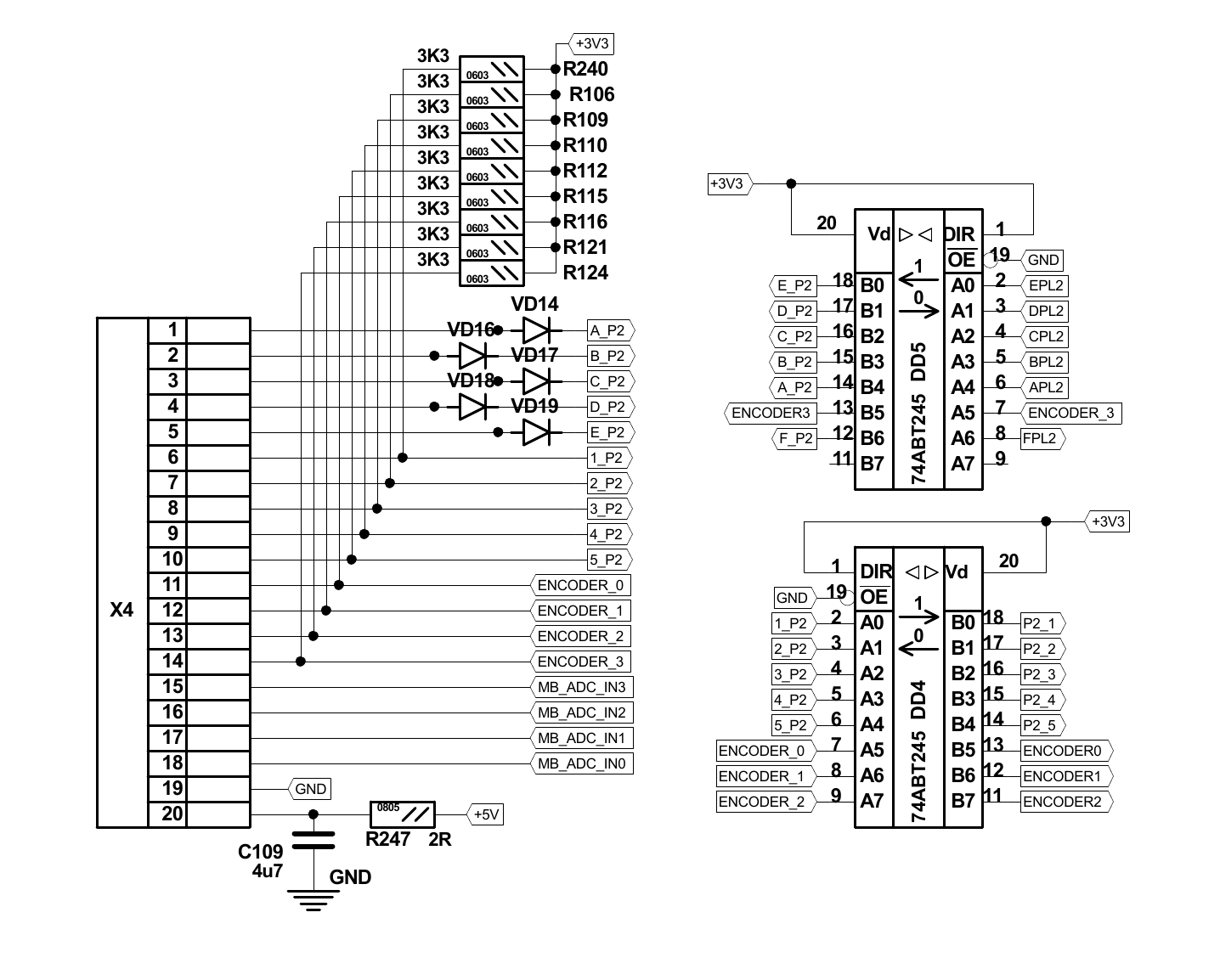

ET7 control board interface to connect external keyboard is shown below

ET7 connector pinout

ET7 connector X4 pinout table

| X4 connector to External 25-keys keyboard | ||

|---|---|---|

| Pin# | Name | Comments |

| 1 | OUT A | Keyboard matrix output pins |

| 2 | OUT B | Keyboard matrix output pins |

| 3 | OUT C | Keyboard matrix output pins |

| 4 | OUT D | Keyboard matrix output pins |

| 5 | OUT E | Keyboard matrix output pins |

| 6 | IN #1 | Keyboard matrix input pins |

| 7 | IN #2 | Keyboard matrix input pins |

| 8 | IN #3 | Keyboard matrix input pins |

| 9 | IN #4 | Keyboard matrix input pins |

| 10 | IN #5 | Keyboard matrix input pins |

| 11 | E#0 | Encoder input (General purpose input) |

| 12 | E#1 | Encoder input (General purpose input) |

| 13 | E#2 | Encoder input (General purpose input) |

| 14 | E#3 | Encoder input (General purpose input) |

| 15 | ADC _ | |

| 16 | ADC _ | |

| 17 | ADC _ | |

| 18 | ADC _ | |

| 19 | GND | |

| 20 | 5V |

PDF: http://cnc42.com/downloads/et7-keypad-dimensions.pdf

DXF: http://cnc42.com/downloads/et7-keypad-dimensions.dxf

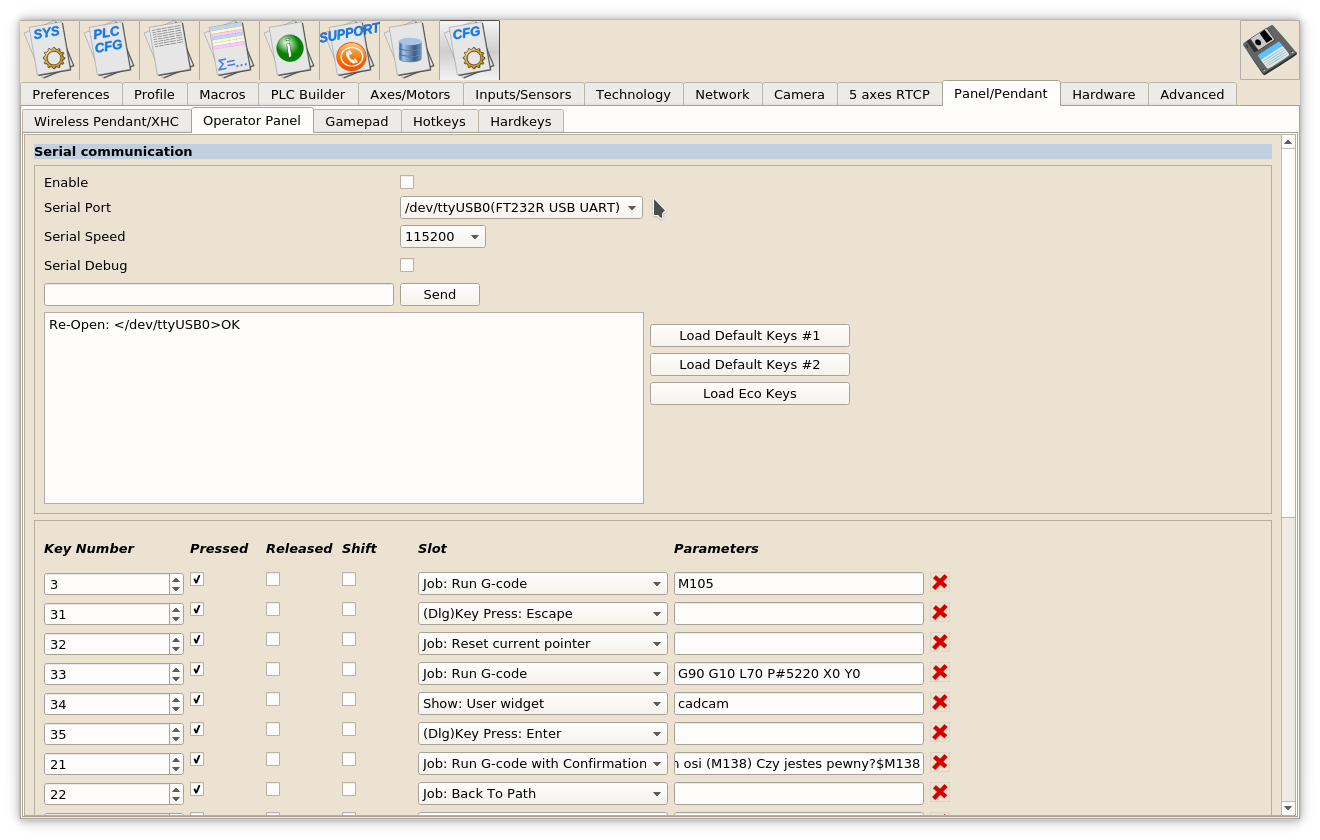

Each key, rotary encoder and the joystick functions can be programmed in configuration dialogs.

Schematics of the external ET7-KEY board is shown below

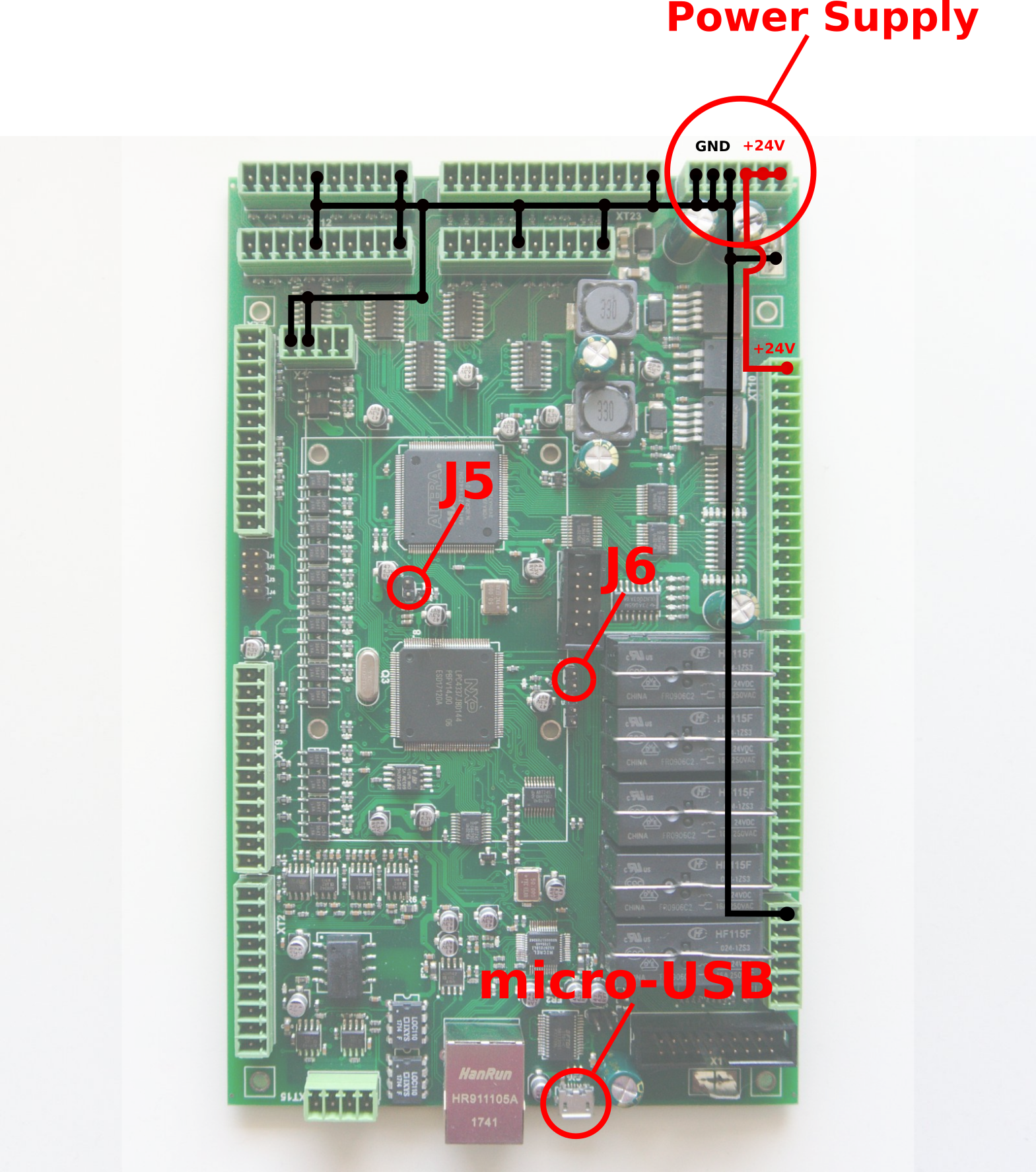

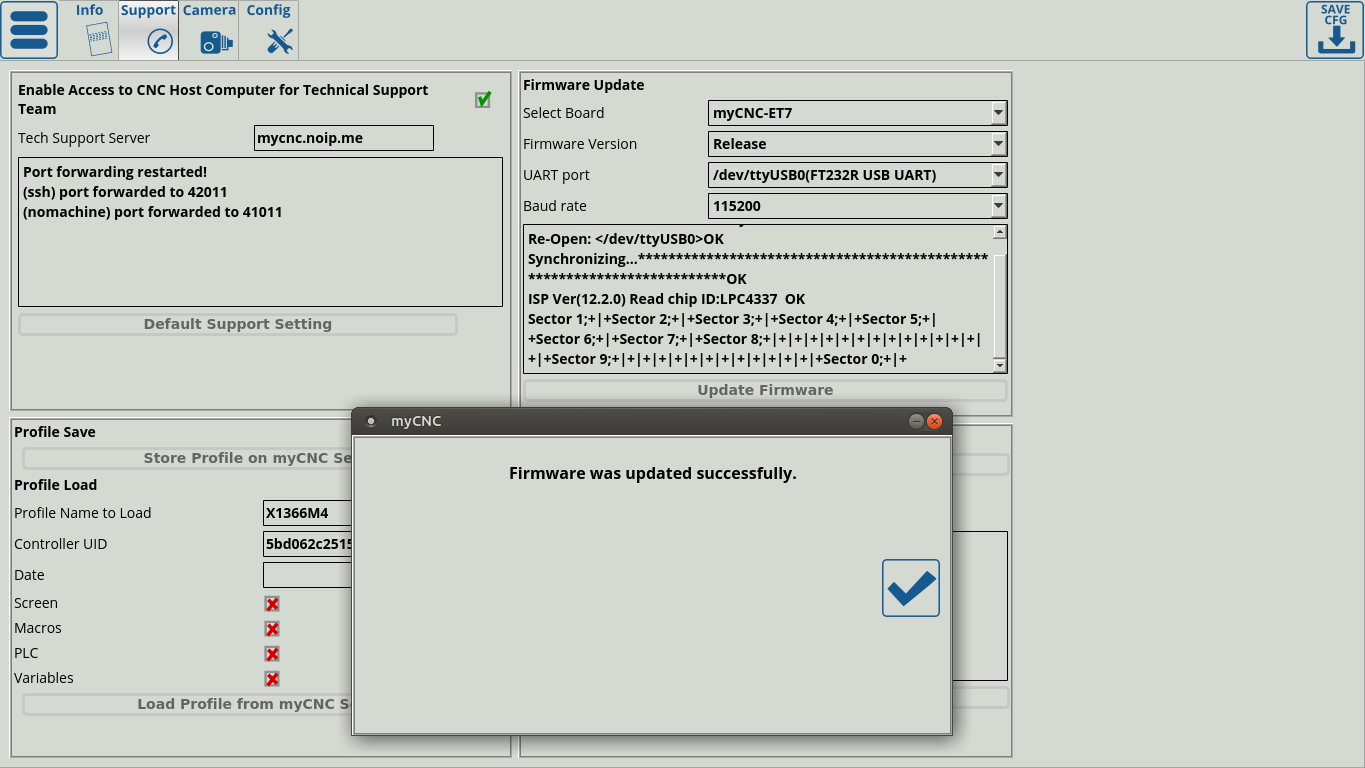

ET7 firmware reflash

WARNING: Unlike updating the myCNC software, the firmware CANNOT be downgraded after a reflash. The myCNC team recommends reflashing the control board firmware as a last resort only, and recommends seeking an explicit confirmation from the support team that the firmware reflash is warranted in order to avoid issues.

myCNC-ET7 reflashing procedure may take up to 3 minutes.

To reflash the board:

1. Plug in the 24V DC power supply

2. Plug in the micro-USB cable into the ET7 controller & a Host Computer with myCNC installed

3. Close jumpers J5(reset) & J6(programming) on the controller board

4. Open (remove) the J5 jumper.

5. Open myCNC software on Host computer (Settings > Support Tab)

6. “Select board” set to “myCNC-ET7”. Make sure to select the correct revision version (R1/R2/R3 or R4/R5/R6).

7. Select “Firmware version” from “Release”, “Night build” or “Testing” (“Release” is recommended)

8. “UART port” - select the port with FT232 attached. If no such port visible, check the micro-USB connection, then close and open the Support tab once again in order to refresh it.

9. Baud Rate set to “115200” for ET7; other baudrate can be selected in case of problems on the 115200 speed

10. Press “Update Firmware” button, Firmware download and reflashing process will be started

11. If “Sector 0; +” message is shown in the debug window, the reflashing process has been finished successfully.

12. Remove all jumpers (J5, J6) and restart the board.

If the reflashing process failed, please check your internet connection and the micro-USB connection, and then repeat the reflashing procedure from Step 3.

myCNC-ET9 (ET7-R4 and above)

The myCNC-ET7R4 (also called the myCNC-ET9) controller is the updated version of the myCNC-ET7 board with some additional functionality. For information on the ET7, please consult the following manual: myCNC-ET7 CNC controller

The board naming is different due to a different chip, which requires a separate version of the firmware from the regular ET7 boards (such as ET7R3).

NOTE: The ET7R5 (Revision 5) and the ET7R6 (Revision 6) controllers use the same ET9 firmware as ET7R4. The functionality between R4 and R5/R6 versions of the board remains the same.

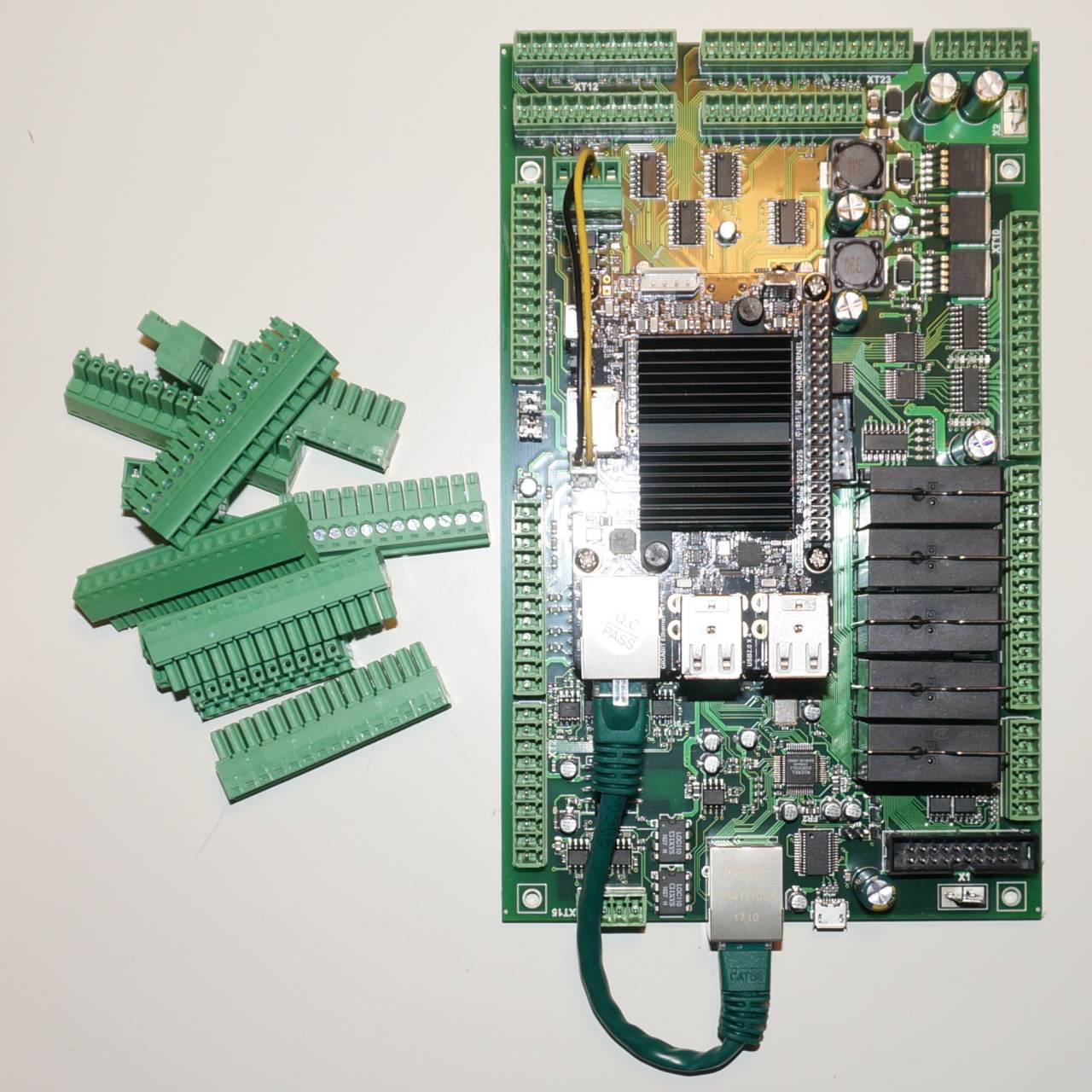

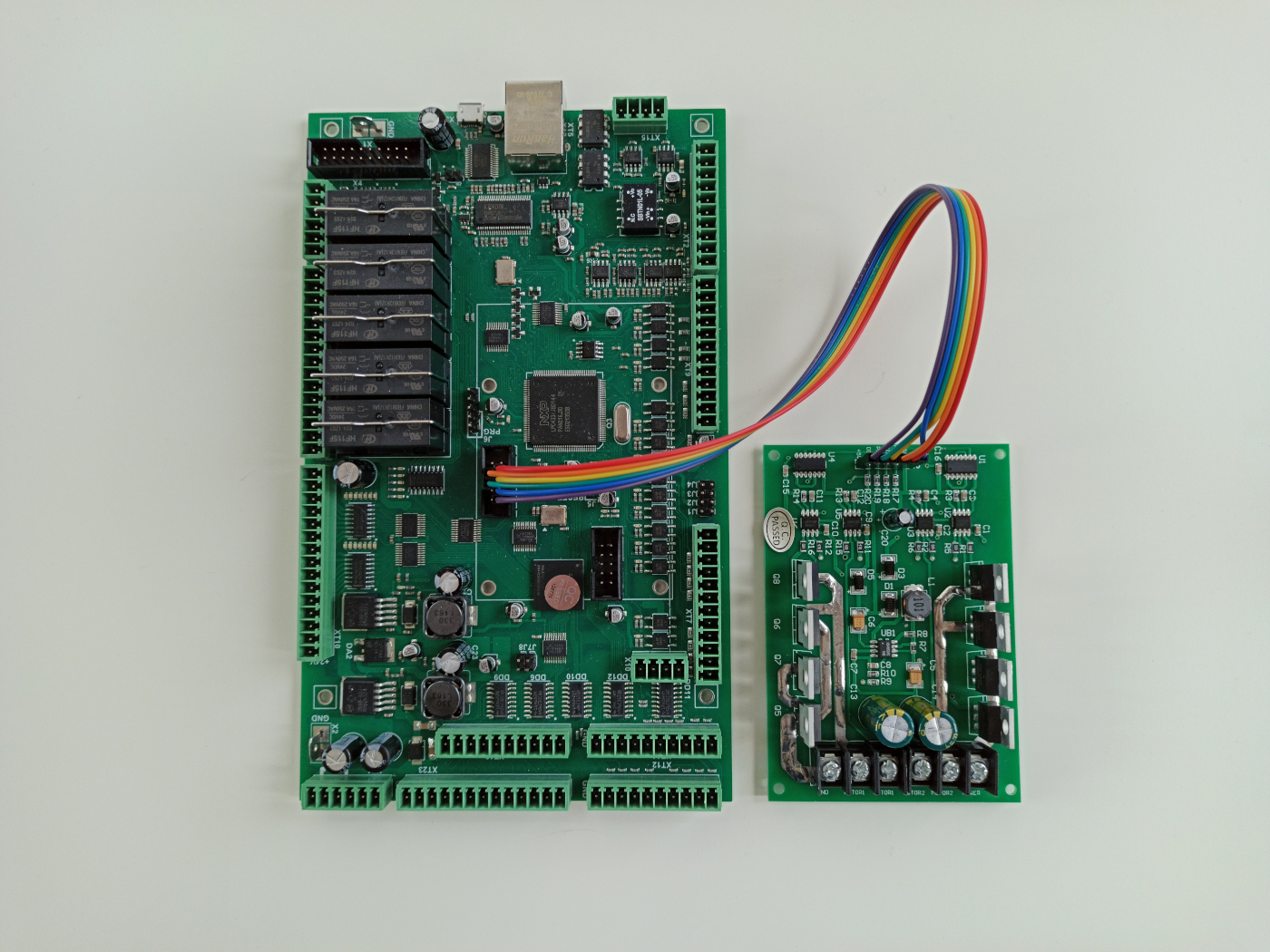

The ET7R4 controller is pictured below:

The myCNC-ET9 pictured with a DC motor driver:

myCNC-ET9 main features in addition to the fucnctionality present on the previous iterations of the board:

- Motor driver can be plugged into an auxiliary connector (outputs #17/#18)

- 2 PWM ports duplicated (PWM1, PWM2)

- Since the driver board is designed for 2 motors, therefore the ET9 has support for both

Reflashing the ET9 board

Reflashing the ET9 board

To reflash the ET9 board, follow the instructions on reflashing the ET7 boards here, however make sure to select the ET7-R4/R5/R6 (ET9) option in the Select Board field.

Failure to select the correct revision version of the board will result in your board being non-operational. Please consult the myCNC support team prior to a reflash should you have any questions.