mycnc:mycnc_setup_examples:plasma_cutting:1024p

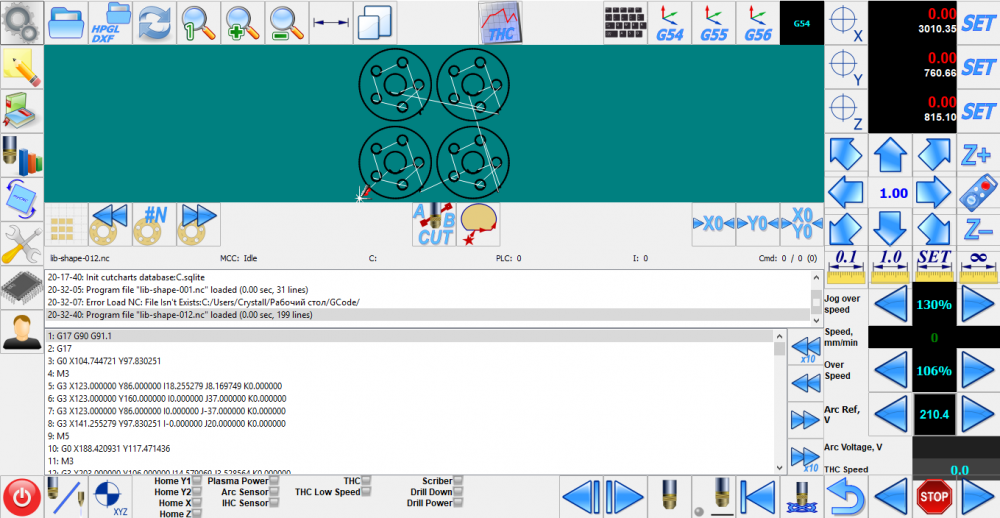

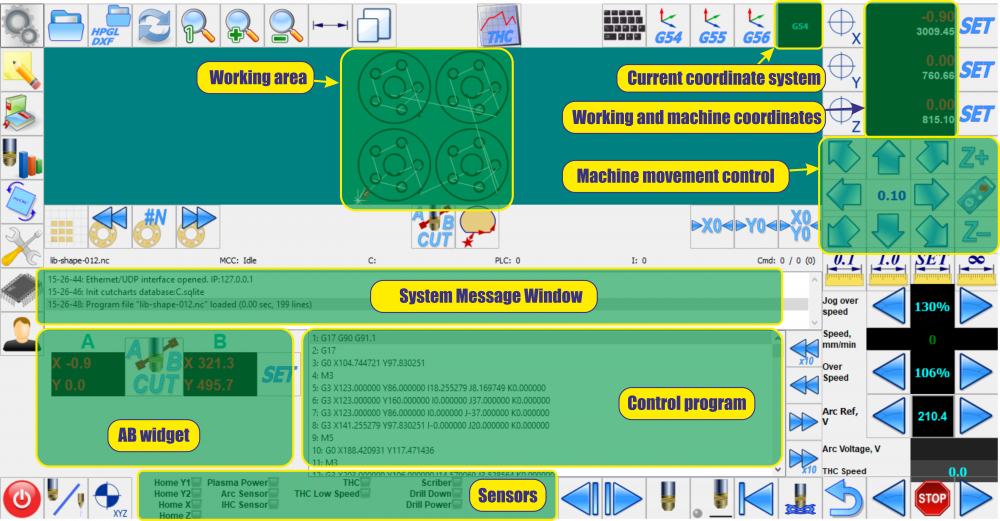

Plasma Cutting profile 1024P-V2 windows and buttons

Basic Windows

Description of buttons and windows

| go to the main window. |

| Nc-list editor. Redirector of control programs. In this editor you can change the previously created nesting patterns, create new nesting patterns. |

| a library of ready standard elements for cutting, milling and other types of metal processing. |

| The window for saving and loading the preset technological mode. A library of technological settings with the option of selecting the cutting mode based on the thickness of the metal, the type of cutting head, and the available combinations of the gas system of the machine. |

| The geometric transformation window of the nesting chart. Rotation by a given angle, correction of sheet laying, mirror transformation of a nesting map along any of the coordinate axes, etc. |

| Basic settings of the program. More details can be found here. |

| System diagnostics window. Verification of inputs, outputs, ADC, DAC, number of installed instrument, current coordinate system, etc. |

| Custom settings. In this window you can transfer any of the frequently changed program settings. |

| Machine shutdown window. |

| Change of cutting technology. Transition from the plasma cutting system to the gas cutting system |

| Download and open the file of the control program |

| Import a dxf file |

| refresh of the visual display of the nesting chart |

| Place the control program on the whole screen. |

| Zoom in of the nesting chart |

| Zoom out of the nesting chart |

| Show dimensions of the nesting chart |

| Show work area with nesting chart |

| The choice of coordinate system G54 |

| The choice of coordinate system G55 |

| The choice of coordinate system G56 |

| Virtual keyboard - allows you to enter commands without connecting an external computer keyboard |

| To reset to zero the working coordinate by X |

| To reset to zero the working coordinate by Y |

| To reset to zero the working coordinate by Z |

| |

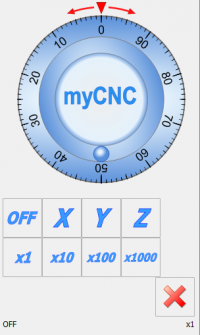

| Run digital pendant. |

| The window for diagnosing the positioning system of the cutter over the sheet during cutting, with the ability to adjust the speed and accuracy of the system. Setting the PID of the tracking system. |

| Run homing for X coordinat |

| Run homing for Y coordinat |

| Run homing for XY coordinat |

| Opening a widget to duplicate one part for the entire desktop or for the required amount. |

| Search for the previous cut-in point |

| Search by the number of the desired point of plasma switching. |

| Launch the widget by two points. This function allows you to cut a sheet without composing a program and without using manual control. |

| Run the widget “cutting from the edge of the sheet.” The function allows you to cut directly from the edge of the sheet to the operating point of the control program. This function is necessary when the thickness of the metal exceeds the capability of the cutting source for punching the metal. |

| Search for the next cut-in point |

| Go back through the control program for 10 lines. |

| Go back through the control program to the previous line. |

| Go forward through the control program to the previous line. |

| Go forward through the control program for 10 lines. |

| Set the step size to 0.1mm. When you press any moving organ, the machine will move the cutting head by 0.1mm and stop. |

| Set the step size to 1mm. When you press any moving organ, the machine will move the cutting head by 1mm and stop. |

| Set the step size to 10mm. When you press any moving organ, the machine will move the cutting head by 10mm and stop. |

| Set the step size to 100mm. When you press any moving organ, the machine will move the cutting head by 100mm and stop. |

| Set the move step to the specified value. When you press any movement organ, the machine moves the cutting head to the specified value and stops. |

| Setting an infinite move step. When you press any moving body, the machine will move without restrictions. |

| Go to the control program one step back. |

| Go to the control program one step forward. |

| Turn off the cutting function and turn on the drawing function. When this button is pressed, the cutting function is turned off and all operations on the control program occur without cutting. This function ignores all control codes associated with turning the cutting on and off. |

| Manual ignition. Inclusion of cutting at any place in the work area, followed by manual grinding with a machine with cutting included. |

| Reset the operating point to the beginning of the control program. |

| Binding of the start of the control program to the operating point |

| Return to the working point. |

| Move the control program backward |

| Stop program |

| Move the control program forward |

mycnc/mycnc_setup_examples/plasma_cutting/1024p.txt · Last modified: by ivan